Or "Resilience"

Preparing the shoot

When we arrived, we saw a very well setup field. Mostly for HFT, but perfectly adequate to our needs.

Here are some more pictures of the excellent Lazio Airguns field:

Sadly, some of the members of the team were experiencing extreme delays in getting to Rome. Some shooters even arrived without a rifle to shoot, and so, some agonizing trips to the Fiumicino Airport ensued, trying to get hold of the guns.

In then end, "with a little bit of Luck" all shooters and guns showed up, in time for the official "Zeroing/Practice range" to open.

The two terrains

GrottaFerrata is a small town in the "Parco dei Castelli Romani" that basically houses all the "Summer Manor Homes" of the most powerful families in Rome.

Next to GrottaFerrata is the well known (and famous for its wine) town of Frascati. Where the new "Social Venue" was located, Villa Tuscolana.

But the terrain between GrottaFerratta and Frascati is pretty similar:

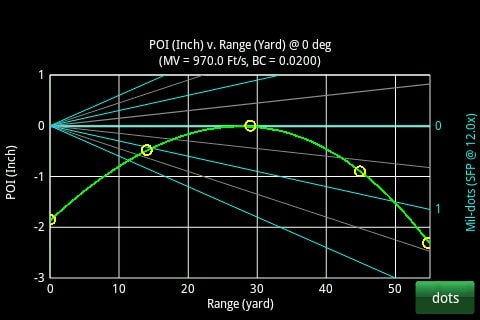

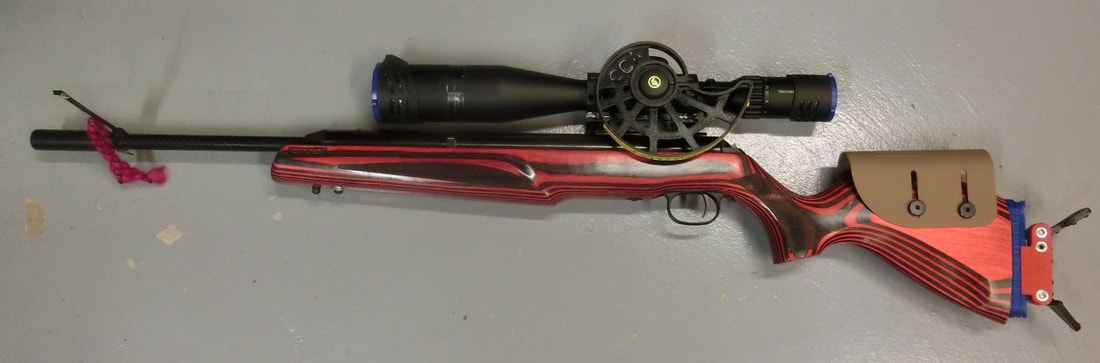

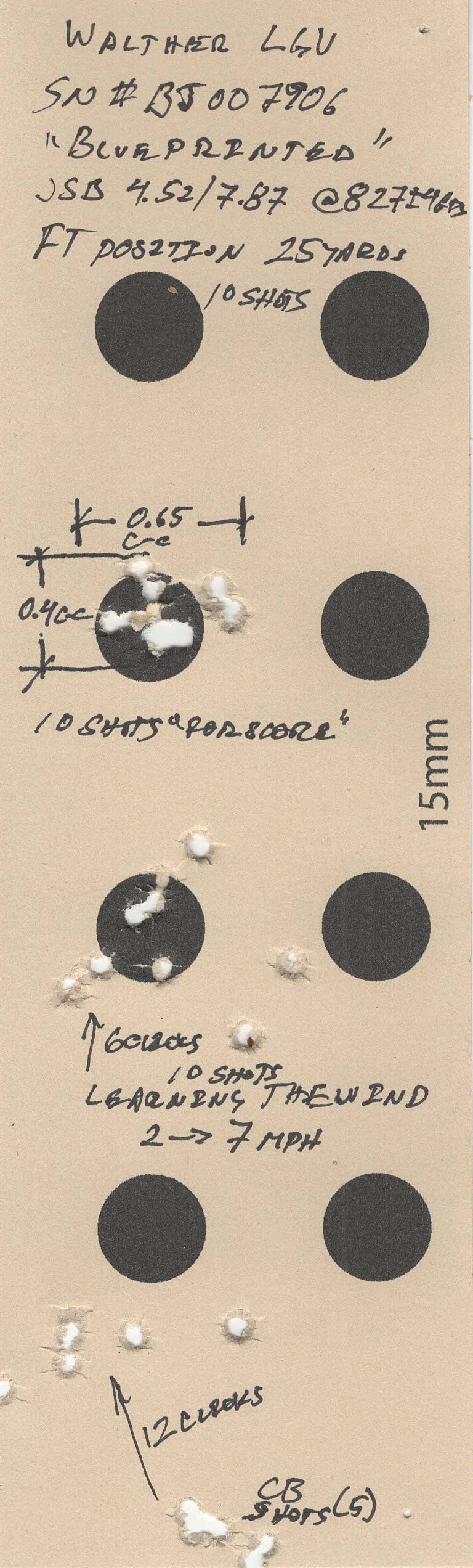

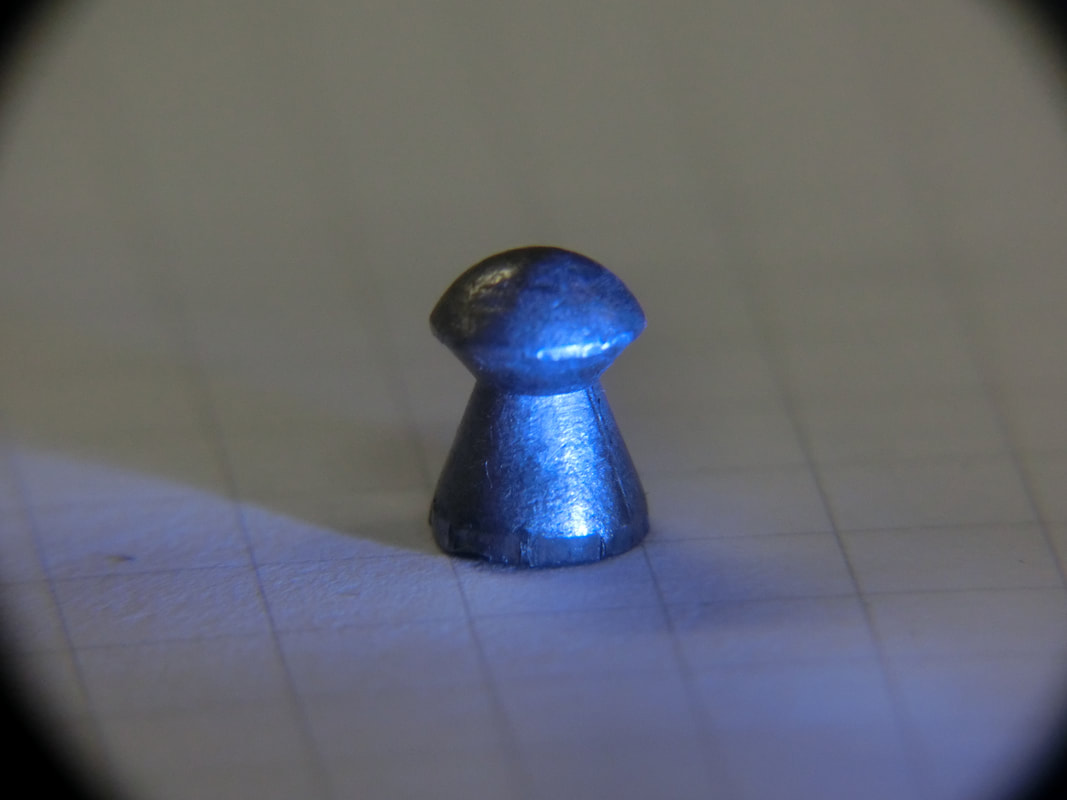

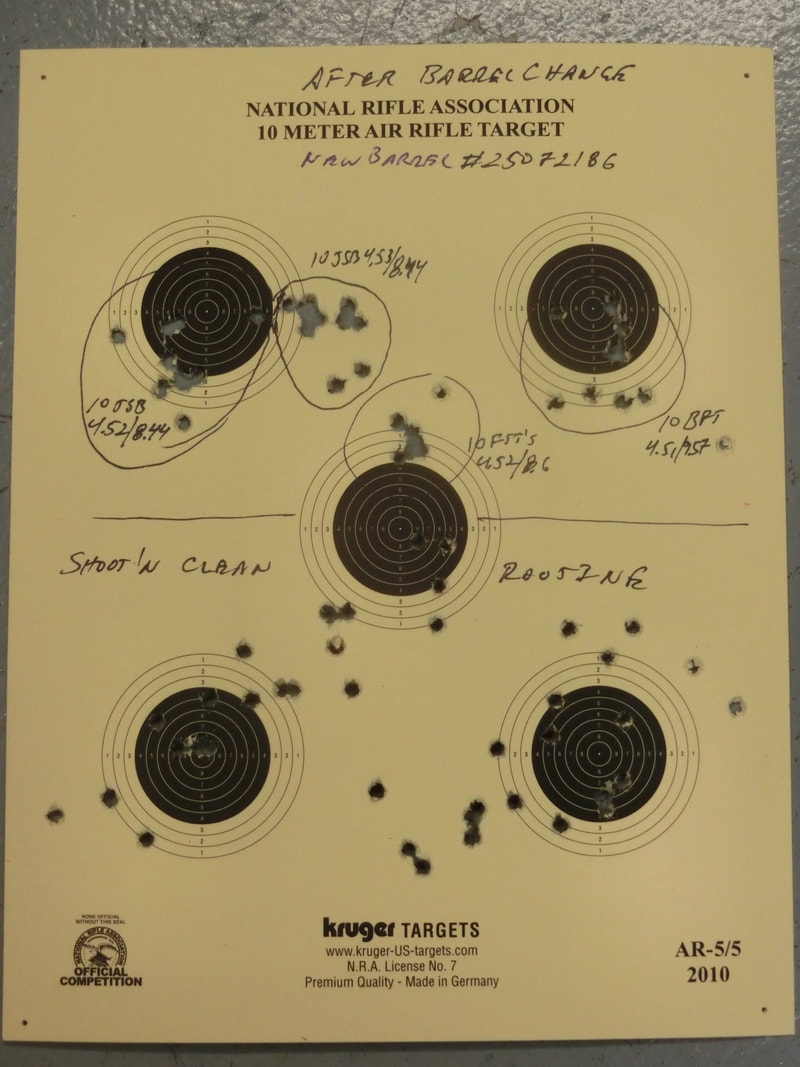

As soon as we could register our equipment and get it approved for competition at Villa Tuscolana, we adjourned to the range and took some time trying to learn the conditions.

RSS Feed

RSS Feed