We were talking then about the Diana 280. A small, handy carbine that was designed from the ground up to yield 12 ft-lbs. Sort of a "short action" D-34.

I obviously understood what he was referring to by "de-tune", but then it struck me that the specific way of putting it was very American.

If you "tune" something it is to get more power out of it, ¿Isn't it?, ¿how could there possibly be ANY other understanding of the verb "to tune". At least within the airgunners' circles.

That exchange prompted a train of thought that carried from my insistence in "tuning for optimal stability", to the sometimes jokingly expressed recriminations about issuing D-54's at "NERF gun level" of 12 ft-lbs.

Since there is precious little I can do for the time being between the weather and my health, I decided to dig on my records, do a little bit of experimenting (not much, mind you), and then respond with some facts.

Usually, when I build a CCA WFTF D-54 "engine" (understanding this as the metal powerplant heart of the house section of the gun), I have to cut off 2 coils and change from full power springs.

¿Why?

To answer that we need to go back to how the Int'l HMO Piston was designed.

Back in 2007 I was designing the piston to yield at least 12 ft-lbs when used in Latin America.

Latin America has a number of country capitals that are above the 7,500 feet above sea level range.

Piston airguns do not have their own air supply, they work with whatever is available in the environment.

Experience had shown that at that altitude, power output was reduced to about 84% of what could be obtained between sea level and the first 1,000 FASL; so the piston was designed in such a way as to yield 14 ft-lbs. at sea level.

Some calculations and a little final tweaking yielded the current spec for the Int'l HMO piston.

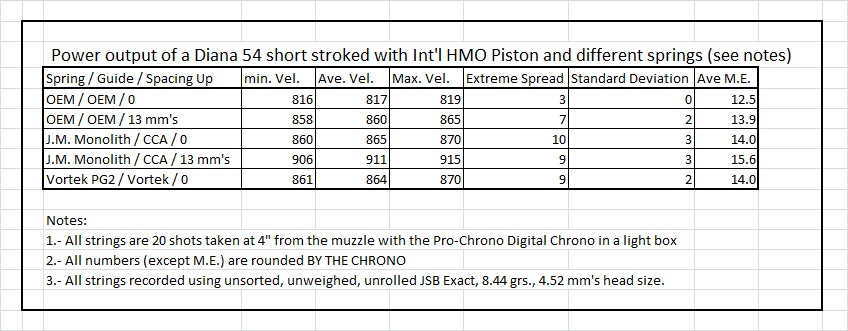

So, what CAN you get when you put an Int'l HMO piston in a D54?

I gathered some data, ran some experiments, and these are the results:

Cocking effort of all these setups was under 23# of peak force.

It is important to mention that even with 13 mm's spacing up, the spring is much less stressed than the OEM arrangement where the stroke of the OEM piston requires a compression of a full 100 mm's. So expected life of the spring should be quite interesting. Perhaps not the 20-30,000 rounds of the least stressed WFTF version, but interesting none the less.

¿Could you get more power?

A little, yes, but the spring is fast approaching the region of diminishing returns.

In this context, if someone absolutely WANTS to shoot heavy pellets, the full stroke gun is the only option.

I emphasize the word WANT because when you "tune" for stability, the BC of the 8.44 pellet approaches real fast the BC of the 10.3. Thereby negating the perceived advantage of the heavy pellet either in trajectory or in wind deflection.

In most instances I've seen in the field, driving hard the 10.3 pellets usually yields BC's that are inferior to the lower weighted projectiles driven to reasonable speeds. And by driving hard I mean that even a very capable engine like the D54 is not really made to yield more than 17½-18 ft-lbs in 0.177" cal. which means a 10.3 grs. pellet having a MV of 875 fps. Not as an airgun. Guns that yield more than that are usually dieseling to different degrees and that, again, usually carries over an increased probability of pellet deformation upon firing, which will degrade the BC of the pellet in flight; and inconsistencies as fuel is burned up.

In larger calibers, up to 0.22", the engines are quite capable of delivering more power due to an increase in Expansion Ratio.

Sorry I cannot post targets; with so much snow I found it impossible to do any testing.

Do NOT put too much emphasis on the uniformity of MV's. As long as MV's are within an extreme spread of 15-17 fps, which SHOULD translate into Standard Deviations of 5-6 fps. you should not worry too much. I've seen too many rifles shoot very uniform MV's just to be disappointed at the poor results where it counts: AT the TARGET.

Keep well and shoot straight!

RSS Feed

RSS Feed