And with winter temperatures getting more and more extreme (CNN reported 150 million US Citizens under Wind Chill alert for 2018 New Years Eve and record lows expected in 27 locations, with further 24 record-breaking lows for today -Tuesday-), I think it is normal to start thinking about the long term future of the winter hunt or FT Match and how to prepare for it.

Some may say that the solution is a PCP, but that is not quite right. Filling procedures need to be different in Sub-Freezing temperatures than in warmer conditions, and the lubing of the hammer/action also needs some attention. Shot count may or may not be affected, it depends on how your regulator works (or not) at sub-freezing temps.

Sadly, there is a lot of misinformation out there, from some manufacturers claiming that their (insert the name here -Nitro Piston / Re-Axis / Gas Piston / NP2 / Vortex Gas Spring, etc.- ) are not affected at all by cold weather, to those "experts" that perform tests with large freezers and/or in cold cities (there are about 14 cities in the US and their urban areas with populations in excess of 1 million that statistically have more than 100 freezing days in a year, and the list is growing), that show decreases in performance of between 8 and 13%

RANT WARNING!

IMHO:

Some of those videos perform what I would call "Scientific Murder".- invoking one bit of science to explain everything that is going inside a cold airgun, most of them use the Gay - Lussac Gas Law, which a particularization of the Ideal Gas Law.

In their minds, the pressure in a vessel that is dependent on the temperature once a specific volume of gas has been sealed in, is the all-explaining, all-encompassing law of physics that explains the decrease in performance of some airguns (those tested).

And the fact that the reduction in MV coincides numerically with the calculation of the loss of pressure is the proof-positive that all gas springs HAVE to suffer the same reduction in output.

Problems are:

1.- The Gay-Lussac Law in essence is just a manifestation of the Law of Conservation of Energy, therefore MV has nothing to do with energy unless we understand that there is a quadratic relation between them

2.- There are other aspects besides the "spring force" that determine the output of a gun. Some guns are more efficient than others, some are less. From seal sizing and hardening with cold, to lube thickening/sticking, to lead hardness, to air density, and others, the "Force" of the spring is definitely not the only quantity that matters.

The OSS (Over Simplification Syndrome) is a common human trait. We generalize the bad things that happen in our life and attribute it to one single cause of our choosing (from the specific "god of ---", to "those blooming inmigrants", to "those -expletive- -religious group-") without stopping to think that perhaps our problems are more complicated than the one-dimensional life we imagine.

It is so common, in fact, that it's one of the preferred tools of tyrants to control a population: Drive down the educational standard, turn them all into simpletons, then control them through their fear of -mostly imaginary- enemies.

RANT OVER

So, let's look in detail at what can happen when one gun is prepared, from the beginning, to be as stable as possible under all environmental conditions.

Granted that this is another one of those "ONE GUN" experiments, but in this particular instance what was done to the gun is a KNOWN quantity, whereas in the cases I've ranted about above, the specific condition of the specific test gun is a complete unknown.

An important factor here is to define what is "cold".

When we landed in South Connecticut some years ago, we took it for granted that winters with temps in the 258° K ( about 5° F) would be normal winter temps. Then we started noticing the temps in Minneapolis, Chicago, Minnesota, Milwaukee, Rochester, etc.), and realized that there were much colder places.

What has changed in fairly recent years is the deepening of the "Polar Vortex" that has driven the winter temperatures in the EAST of the US to record lows year in and year out.

Then we moved to Maryland and I hoped I would not have to shovel the usual 9 ft of snow and that the winters would be less harsh. Well, so far at least, one of the hopes is true. No shoveling till today, but temps in the 260° K (about 8° F), belie the fact that summers here will reach 303 °K (about 86 °F) with over 93% humidity.

So, the tests I am going to describe were done in Maryland, are valid for the gun tested (a 0.20" cal D34 converted to N-Tec) and are not intended to be a "universal description" of what can be expected from the run of the mill, OEM issued, airgun equipped with a gas piston of any name.

The test setup was quite simple:

Do note however, that I am using the infrared lit screens. At least THIS chrono operates with infrared light. And trusting the infrared (heat) emission of a cold sky is inviting disaster in a test.

It started life as limited edition D34 with a short Lothar Walther barrel of our own design, and a Premium stock.

The internals were then changed to N-Tec as described in the above-mentioned blog entry.

The stem of the N-Tec piston was lubed with Ultimox PTFE oil and the OEM seal was lubed with powdered MoS2. The central "dead area" of the seal was filled with a UHDPE bumper.

Piston's skirt was buttoned with UHDPE.

Trigger sears and stem button were coated with dry-lube.

This gun has been tested under fire in a few FT Matches, taking 2nd in the 2016 NY State Championship Open Piston class with a score that would have been middle of the pack with the PCP's:

So, my point is that it is a "Well Characterized" entity.

In the humid Maryland summers at 303 °K (about 86°F) and 95+ % humidity, it shoots the H&N FTT at around 770 fps

In Ohio's Fall, it shot 805 fps at 288 °K (around 59°F) and less than 30% humidity.

So, how would it perform under Maryland winter weather at around 263°K (14°F) and 15% humidity?

The rifle was almost cocked and let down three times before setting it out in the cold to acquire the ambient temperature.

Then it was left in the cold for one full hour.

After a full hour had elapsed, we took a reading of the outdoor thermometer:

Freezing, yes, but not as cold as the Minneapolis winters.

Then we shot three shots for warm-up/conditioning that read: 764, 777, and 787 fps

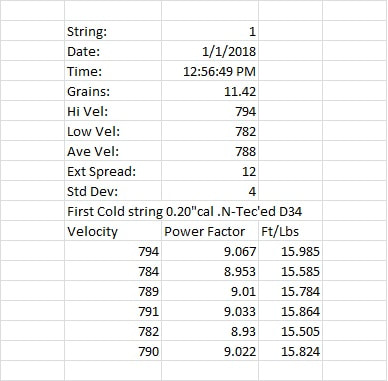

Once we were out of the "cold bore" scenario, we shot a 6 shot string:

So, if the Gay-Lussac Law had predicted something like a 13% difference in the gas spring pressure and therefore a similar reduction in the spring force, what happened with the 11% here?

Of course when hunting, or even when shooting FT, you do not rely on taking 3 shots to then take your "for score" shots. Your gun needs to be able to shoot within reasonable limits even if the next bunny or squirrel (whether metal or not) does not present itself in a short time.

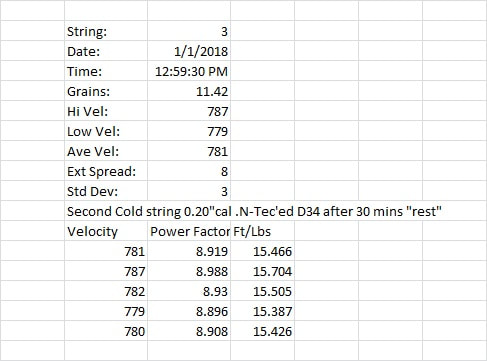

So, I left the gun out and waited ½ hour, these are the results:

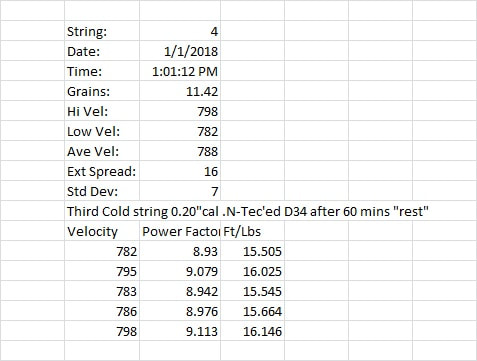

And not happy with only these results I set the gun outside to wait for the next target a full hour, and this is what the gun gave:

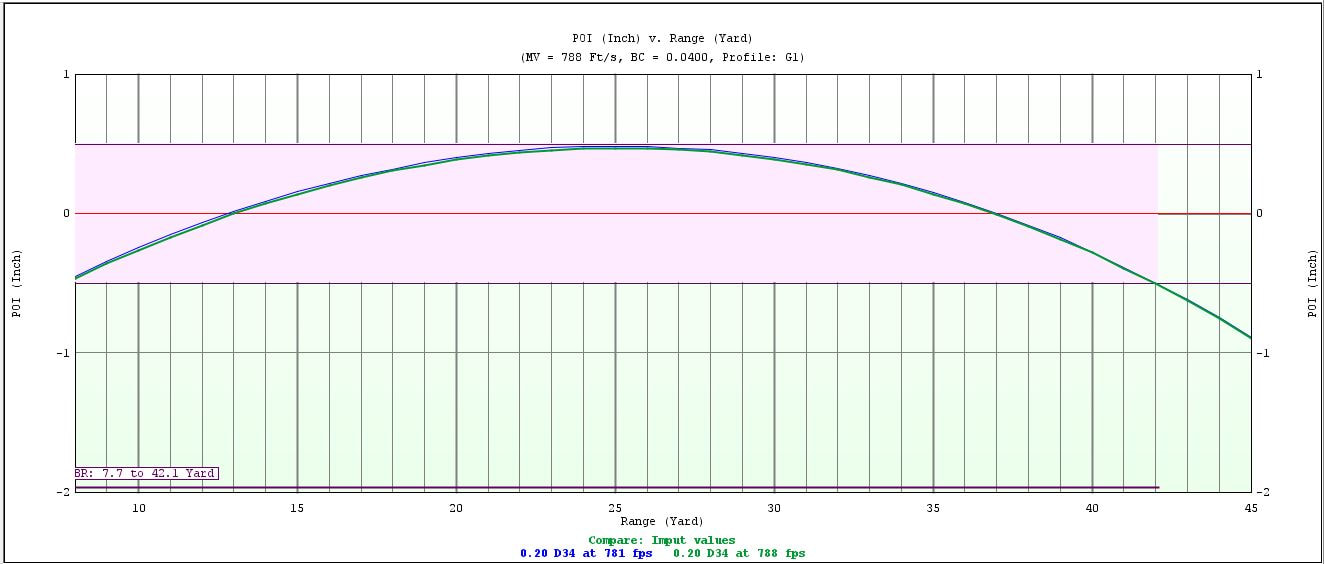

Now, in REAL terms, ¿what can we expect from a change in MV of about 5 to 6 fps (from 788 where we did all our zeroing and trajectory to the first of string "cold" shot of 781-782)? Assuming we are ethical hunters that check their zeroes before actually starting to hunt and possibly, check the trajectory as well.

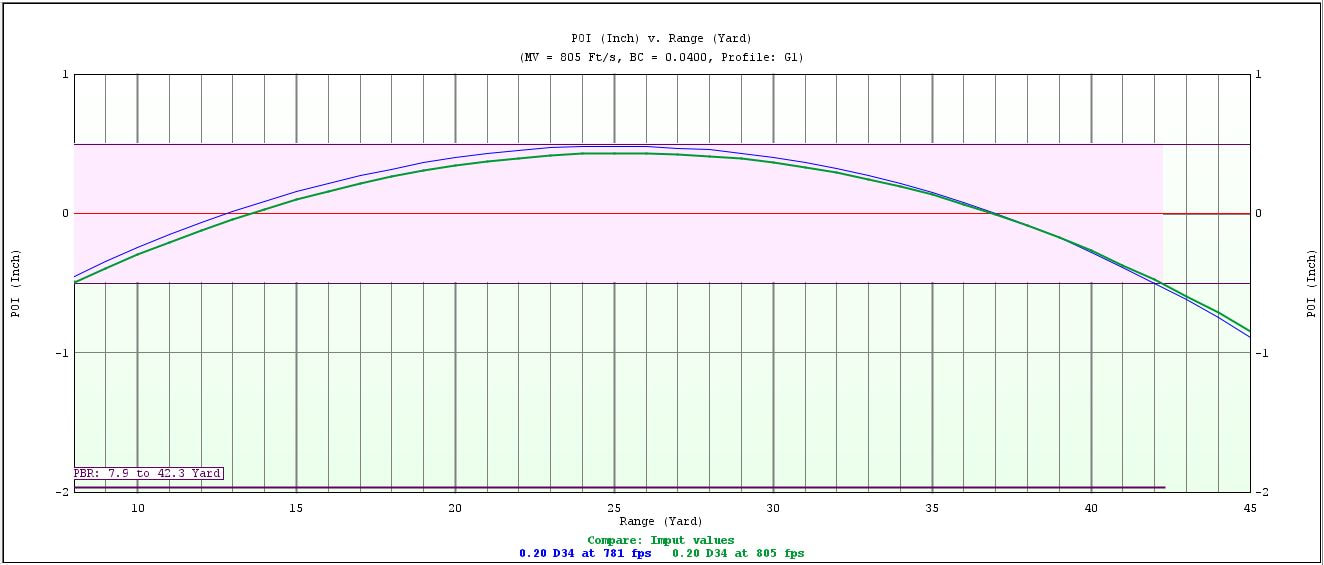

From actual shooting and using PP-Calc, I know that the H&N FTT pellet out of this rifle gives a BC of about 0.04 (yes its a good one).

And that, using a 37 yard zero with a Kill Zone of 1" (½"up or down from the LOS). gives me a PBR of 43 yards.

I would have to be shooting at 60 yards to have one pellet diameter of difference.

So, why do some gas spring guns live up to expectations and some others don't?

Where is the difference between the 2% MV loss and the 13% loss of pressure?

PROBABLY, and this is only a hypothesis because I can only talk about my gun and I will not generalize one way or another, the difference is in what my UK friend Tony Leach calls "The Lost Volume", that is: that swept volume of air that does "nothing" to propel the pellet because it is produced "in excess" under "normal shooting conditions". In other words, this gun may not be operating at PEAK EFFICIENCY, but it is operating at the PEAK STABILITY.

And THAT, my friends is what matters most in reality.

Over the 18 years that I have been dealing seriously with airguns, and the 6 years that I have been doing this professionally, I have learnt only TWO things:

1.- That pellets do NOT like flying faster than 875 fps

2.- That the devil is in the minutiae.

ALL those little details that people tend to disregard as "unimportant", or as "secondary factors that are material and design dependent" are what makes or breaks the reliable performance of an airgun.

Keep well, keep warm, and shoot straight!

RSS Feed

RSS Feed