A nine+1 entry series by John Cerne, Yogi, and Hector Medina

Or, we could even have a joke: "A scientist, a yogi and an engineer enter a bar . . "

Truth is these blog entries (we THINK we will stop at 9) that we plan on publishing every fortnight, started as a casual conversation; not in a bar, but in a forum; were then taken to PM's, and when the project really started to flesh out, formal EMail's started flying all around.

We formally convened on Valentine's Day 2020, and it was truly an auspicious day because everything has gone reasonably well. It has been a pleasure, and a great privilege, to work with these two gentlemen over the last 13½ months.

So, let me introduce my friends to you.

The originator of all this was my friend "WL", who chooses to use ONLY the nick/handle "Yogi", both here and when posting in the GTA forum; he had some very pertinent questions about transfer port (TP for short) geometry (diameter, orientation, length) and when I explained my theories, he ventured the idea of underwriting the effort to ship different guns to different people that could study and explain the possible relationships.

At about the same time, John Cerne, who uses the nick/handle "JohnC" when posting in the GTA, came up with the idea of looking into the overall dynamics of the shot cycle in spring-piston guns.

Now, John has a PhD in experimental condensed matter physics and is a physics professor at a well known research university so, his participation was an opportunity that was too precious to let go.

He was very enthused with some experiments by Jim Tyler on measuring recoil motions in airguns, which were published in the British "Airgun World" magazine..

On my side, I had recently finished the collaboration with Steve Herr (NitroCrushr) about the Four Part "Saga of a DIANA 56 T/H" and, as closure of that report was the receipt of Steve's sled. I hadn't had time to study in detail how to expand its functionalities, so the project proposed by John seemed a suitable vehicle with the ideal candidate. I proposed the joining of forces to all three parties, with the caveat that the TP geometry aspect would be looked at just tangentially, still, Yogi was generous enough to help us get everything underway.

And so it is that we (99% John) have been working in these ideas, developing the tools to START interpreting and understanding the REALITIES behind the APPARENTLY simple mechanical devices we love (and sometimes hate) that are spring-piston airguns.

We FULLY REALIZE this is just the beginning of a new conceptualization. And we realize that we will not do it all on our own. So, part of the intention of this NINE part series is to give (in the spirit of the 1950's "Popular Mechanics" magazine) almost anyone with a modicum of common sense and practical skills, the knowledge and understanding to make up HIS/HER OWN research devices/apparatus, and enable them to start researching into the phenomena that actually make our airguns what they are, what gives them "character", what makes them "tick".

We also HOPE that the industry realizes that the shooters are becoming more and more sophisticated, and that some "Benchmarks" CAN be set that are quantitative and hard-data based enough to dispel all the mystery and "dark-arts" atmosphere that surrounds the "tuning" of spring-piston air rifles, or the qualities of a design.

Now, regardless of how much science you want to put into anything, NOTHING regarding human interaction with machines is written in stone (or parchment / paper). It is not a dogma of faith. Because we, humans, are vastly different. So, we don't purport to have arrived to the ideal recipe for a gun that will work for everyone, but we do think that measuring some key aspects of the shot cycle should enable users to select better the gun that will suit them; and allow manufacturers to come up with better products.

I know that, in a way, we cheated. Why? because we chose for this exercise three of the best examples of spring-piston airguns of all times (Walther LGU, Walther LGV and FWB 124). We know that the dynamics in these three highly tuned airguns are as good as they can get, AND we had the added advantage that the Walthers are basically the same rifle, just one uses the barrel as a cocking lever, the other has a fixed barrel and a separate cocking lever.

BUT, in our defense, we will say that this also allowed us the tangential look into the TP geometry, since one (the LGV) has a long transfer port and the other (the LGU) has a short one.

The nine parts of this series are:

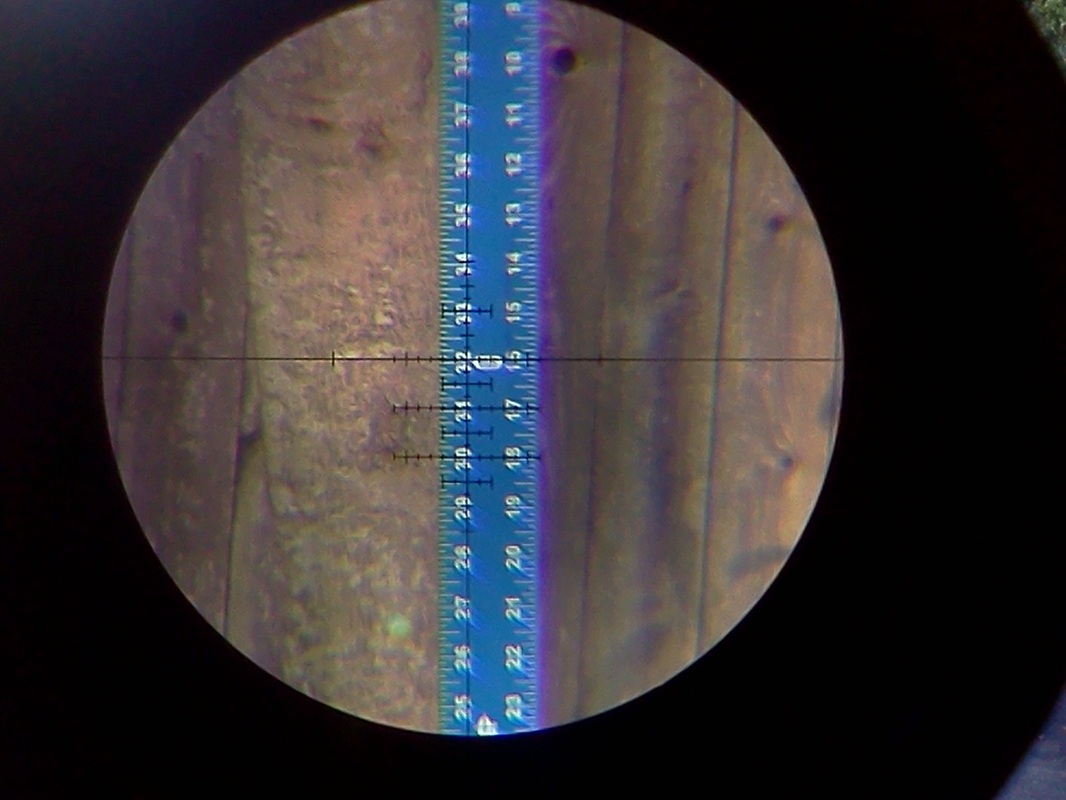

Chapter 1. Diagnostic equipment: How can we understand better what our air rifles are doing?

Chapter 2. How do the Walther LGU, Walther LGV and FWB 124 compare?

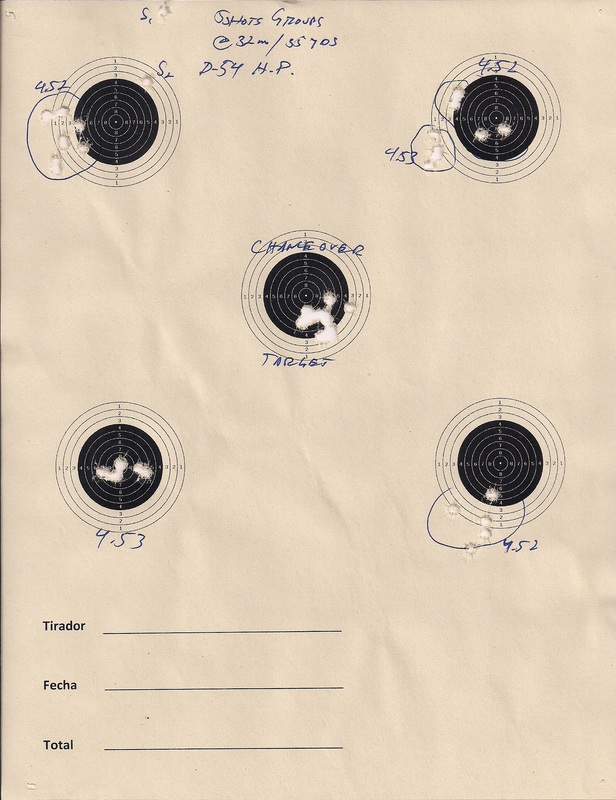

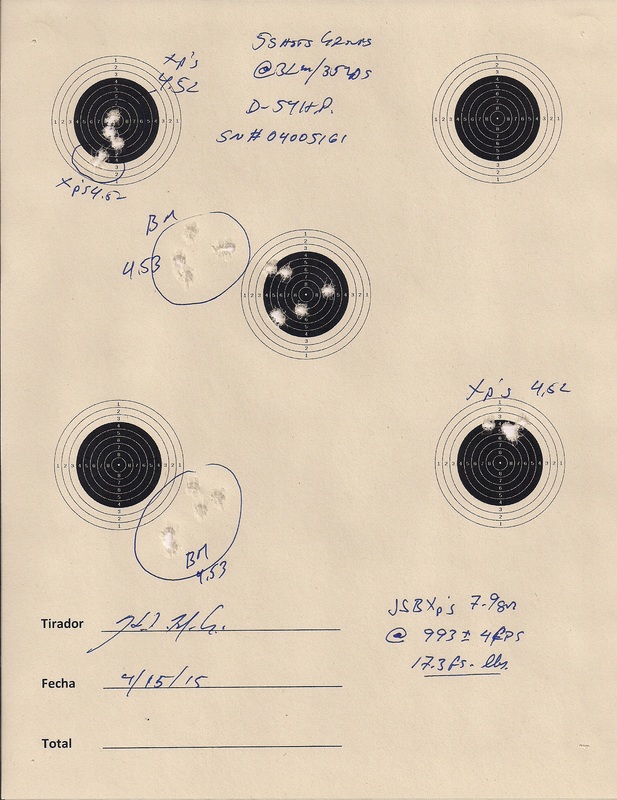

Chapter 3. Group statistics: What can target groups tell us about the accuracy of an air rifle?

Chapter 4. LGU/LGV powerplant swap: How does swapping airgun pistons and springs in an LGU and LGV affect performance?

Chapter 5. Does Krytox improve performance?

Chapter 6. Does more mass in a springer air rifle result in better accuracy?

Chapter 7. Does a higher energy spring decrease accuracy in a springer air rifle?

Chapter 8. What happens when you remove the LGU’s muzzle cap?

Chapter 9. Conclusions: What does this all mean?

So, without further ado, I yield the floor to John Cerne.

RSS Feed

RSS Feed