Luckily, that character has not been lost. I have more than a few good friends that are true "Yankees" in the best sense of the word. One of them lives in Pennsylvania. So we'll call him the Pennsylvania Yankee.

When the LGU first arrived to American shores, we invited some shooters to be part of the pioneering group to purchase the first few. From there, our first review and testing came out:

http://www.ctcustomairguns.com/hectors-airgun-blog/the-walther-sport-family

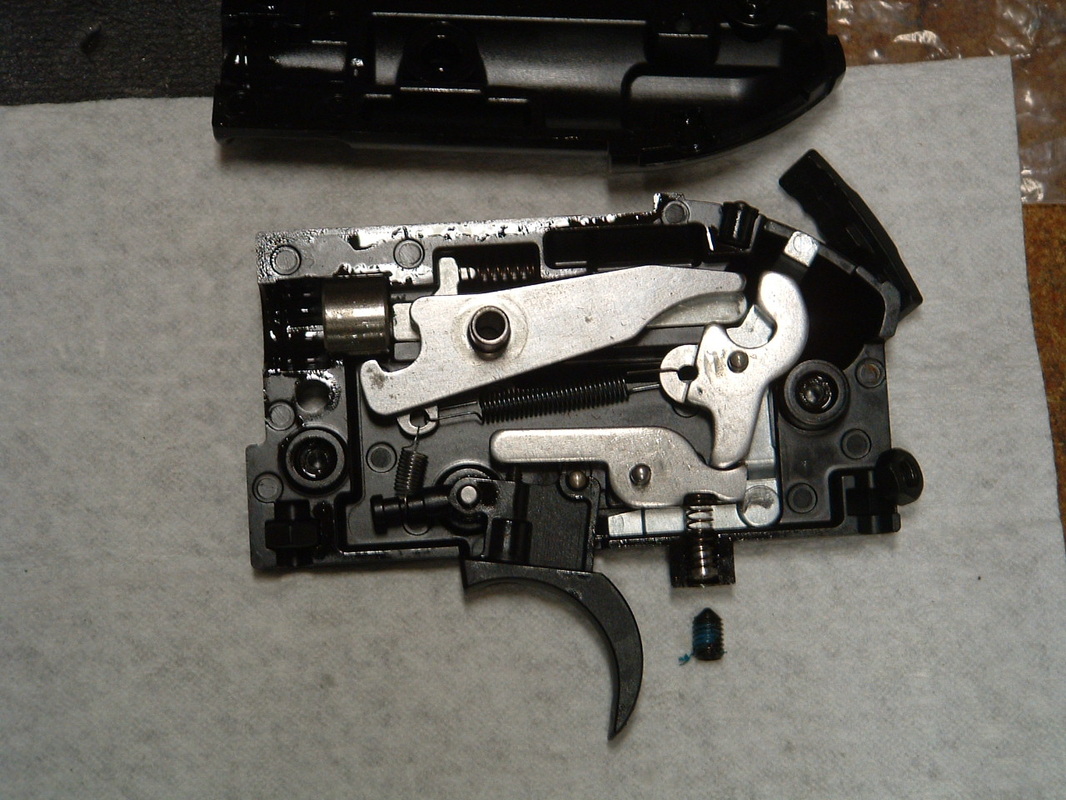

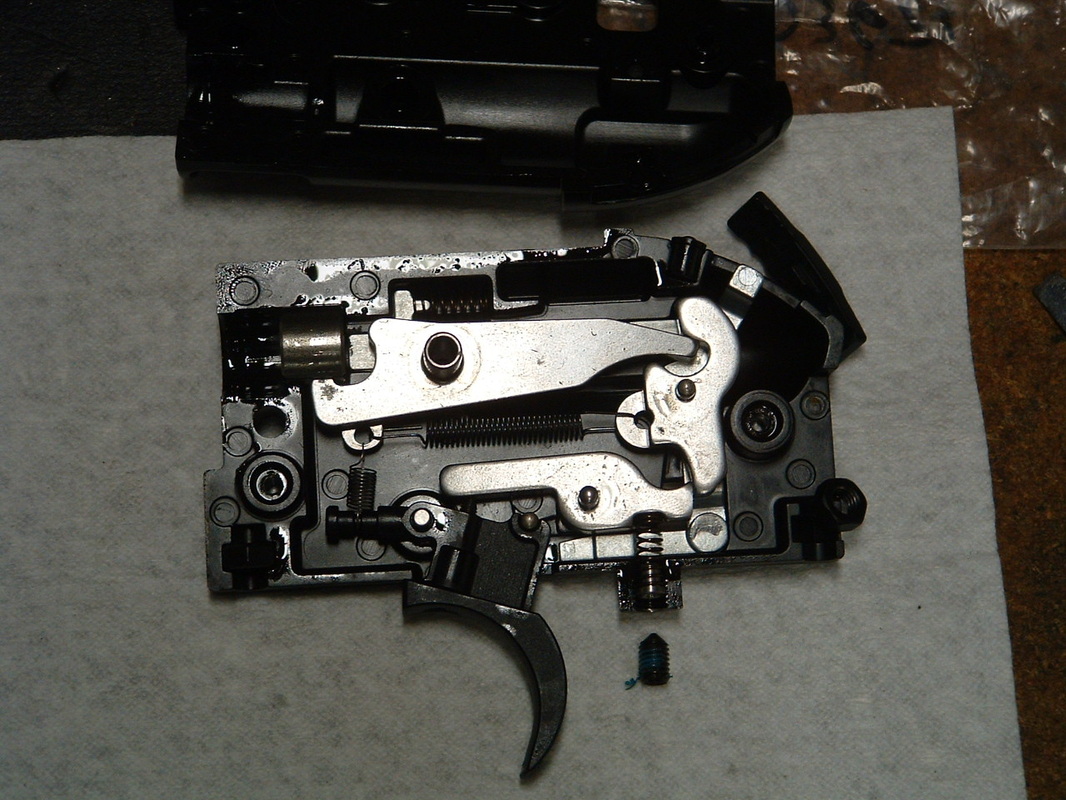

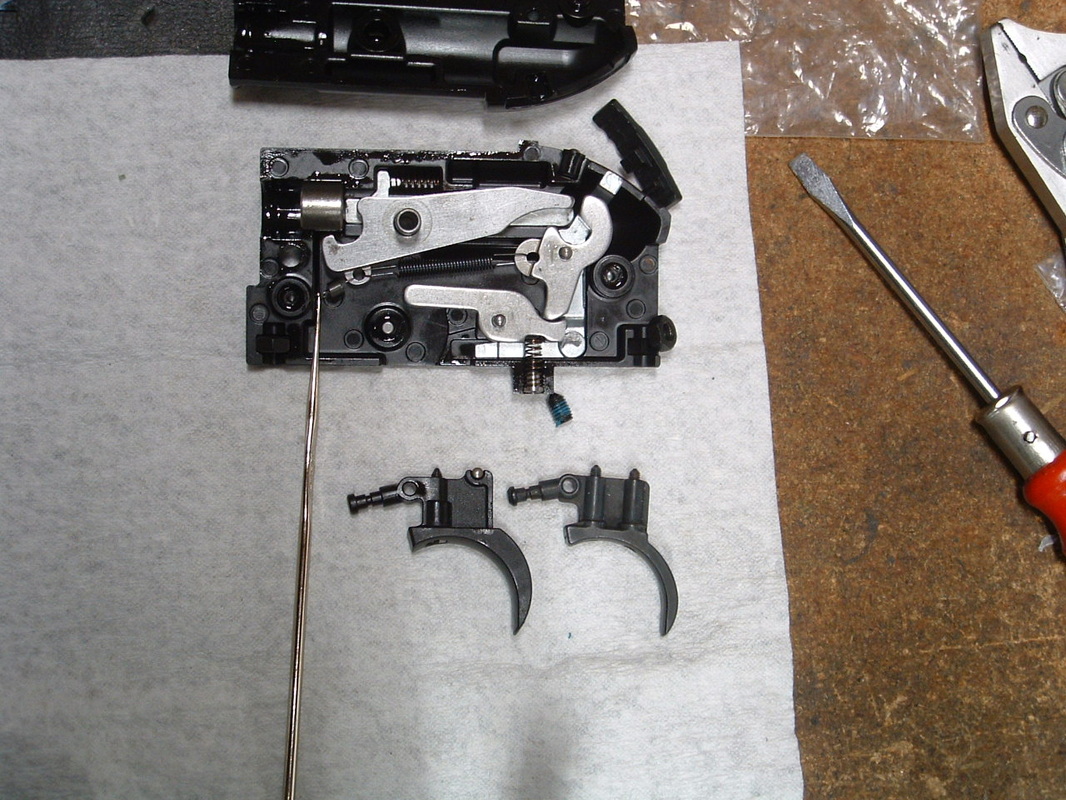

Because the trigger was so terrible and we knew that in advance, from some reviews of the LGV that bears exactly the same trigger unit, we got Match triggers for everyone and posted detailed instructions on how to swap the blades, where 2 out of 3 adjustments are located. That set of instructions can be found here:

http://www.ctcustomairguns.com/hectors-airgun-blog/swapping-the-walther-lgus-trigger

Do note that ALL DISCLAIMERS posted there also apply for this post.

But after a while, my good Pennsylvania Yankee friend and airgun tinkerer extraordinaire came up with some comments and some tests that warranted a further look into the trigger unit first, and then into the power plant.

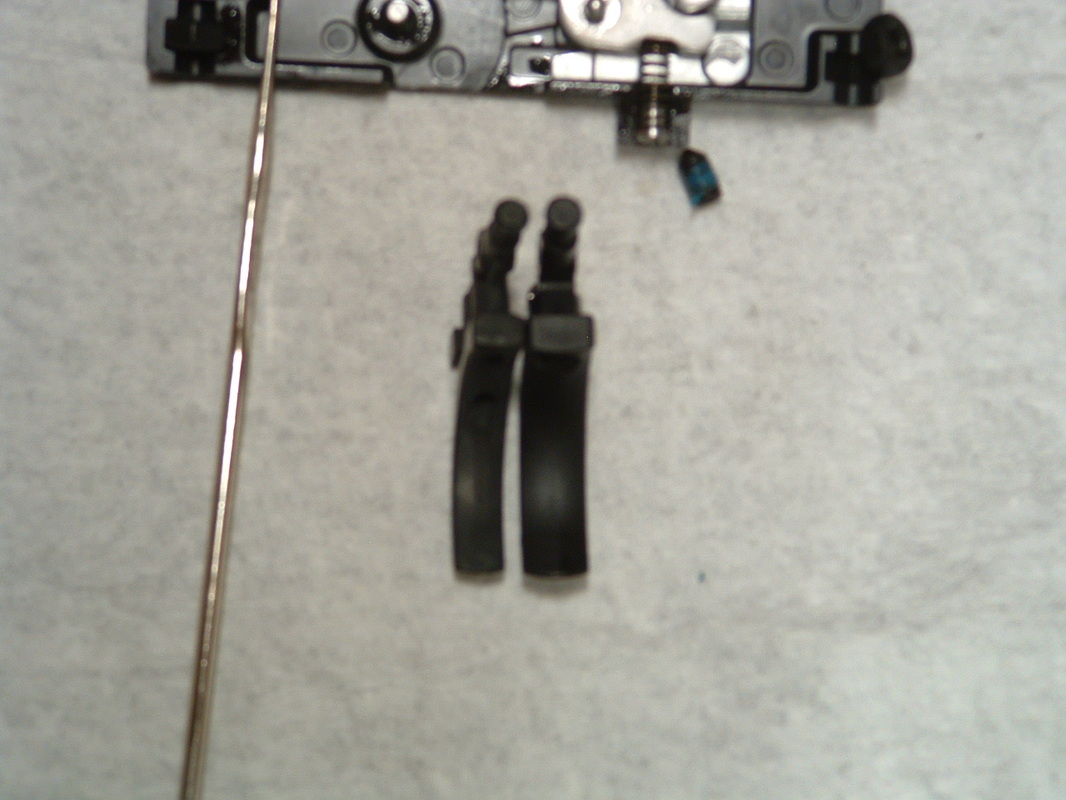

The first thing our good "Pennsylvania Yankee" told us was that there was really no need for the metal trigger.

WHAT!!!!! LOL!

¿After all the chastisement Diana went through when Doc. Beeman started his negative disinformation campaign stating that Diana triggers were plastic and therefore inferior to the point that the T-06 version now incorporates a metal trigger blade?, and now ¿a dyed in the wool airgunner tells me that he prefers the plastic triggers? Well, the world is changing indeed!

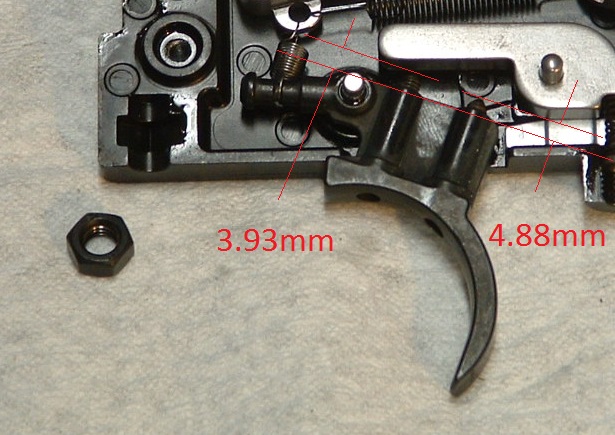

For the UK market (and with a substantial price difference), Walther made available the adjustable metal two screws trigger blade they call the "Match Abzug" or "Tuning Trigger".

It is so complicated that one of the foremost spring-piston shooters in the world, wished someone would post somewhere a "starting point" of where the screws needed to be so as not to loose so much time.

Here is what worked for me in my gun:

BUT, ¿what could be done with the OEM plastic blade to make the trigger crisp and clean-braking?

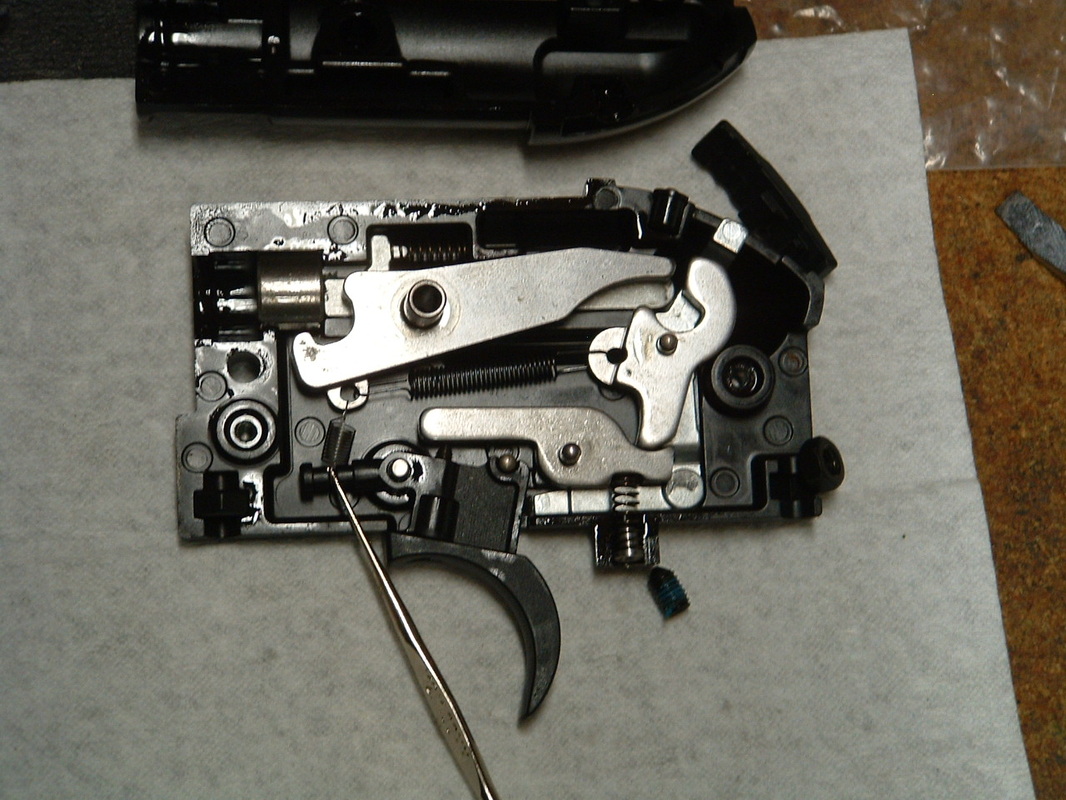

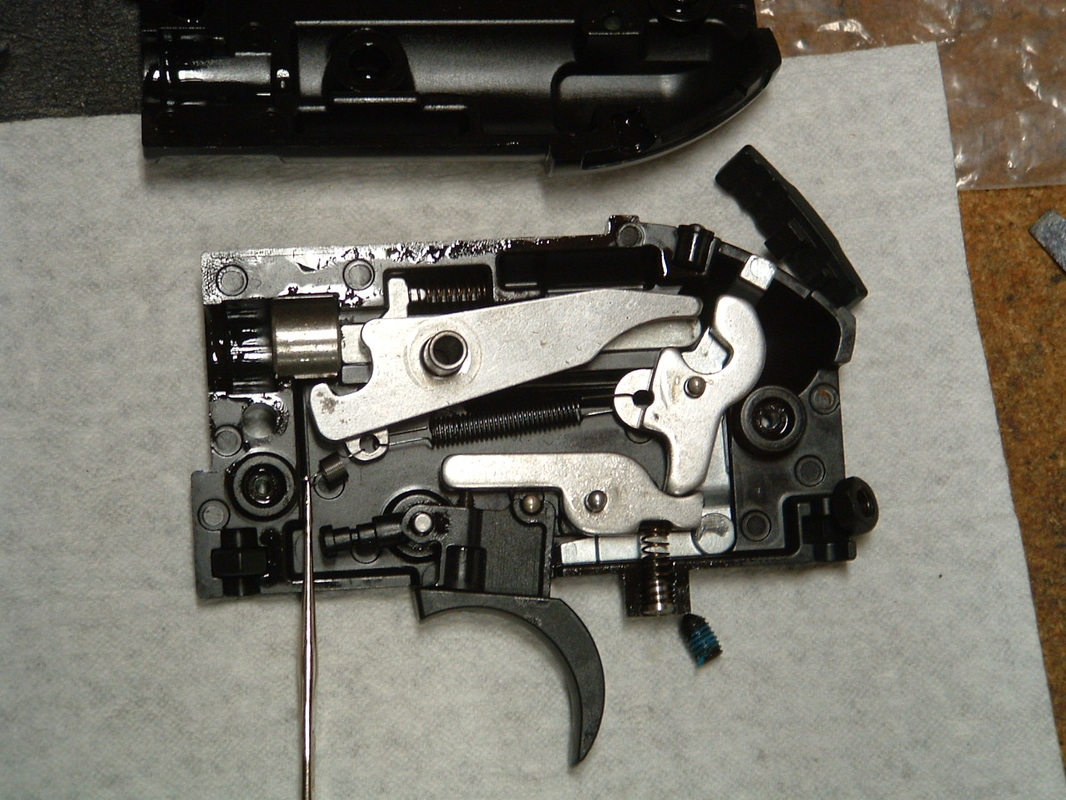

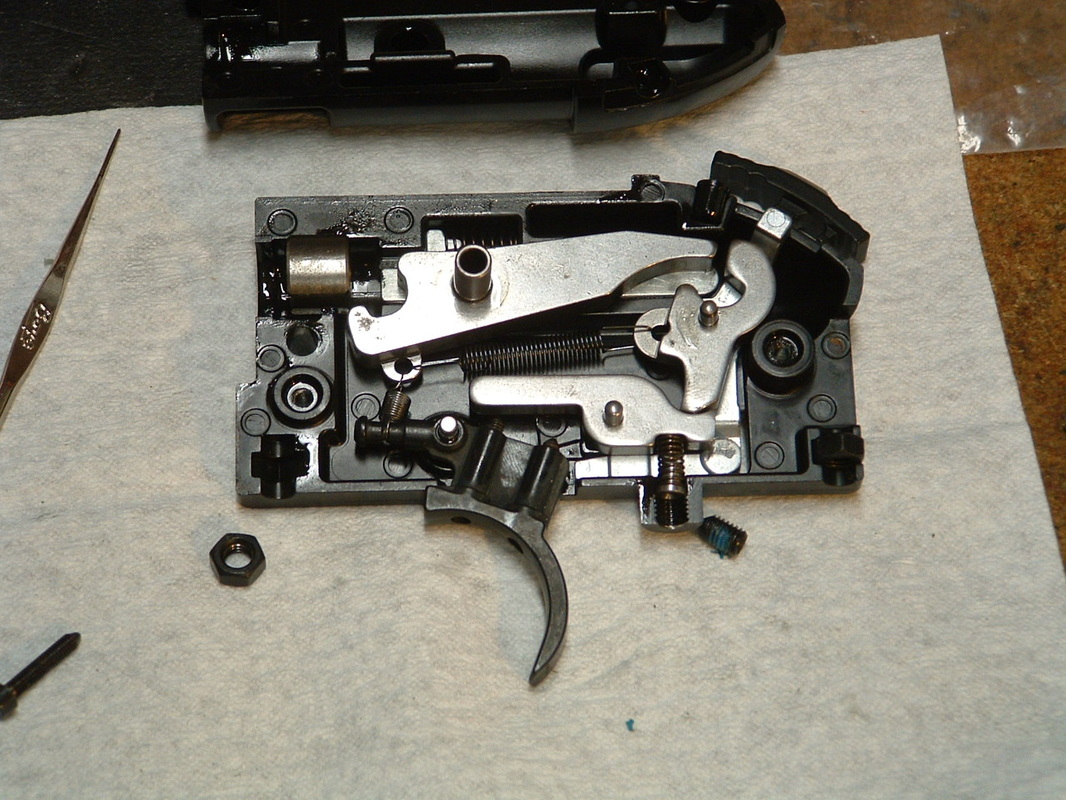

Part of the answer is to polish the surfaces. Stoning is one way, but not the safest.

Jeweler's rouge works better, though it takes patience in hardened surfaces, it is also the least prone to failure method because it removes so little material that the surface hardening of the trigger parts is preserved.

The other part is to round and polish the screws' faces, whether it is the one screw of the plastic blade or the two screws of the metal blade, making the screws pointed against a gritty surface is not precisely the best way to get a smooth, crisp, clean, repeatable trigger release.

After thorough testing I can say that it is true, the single screw trigger blade feels better, releases crisper, is more gentle, predictable and consistent than the metal blade with the two screws.

The metric screw (M3X0.5X20 or 25) will cost you substantially less than the metal trigger blade and, above all, you do not need to disassemble the trigger unit/rifle to do this swap.

Doing more with less, ¿what could be more "Yankee" than that? LOL!

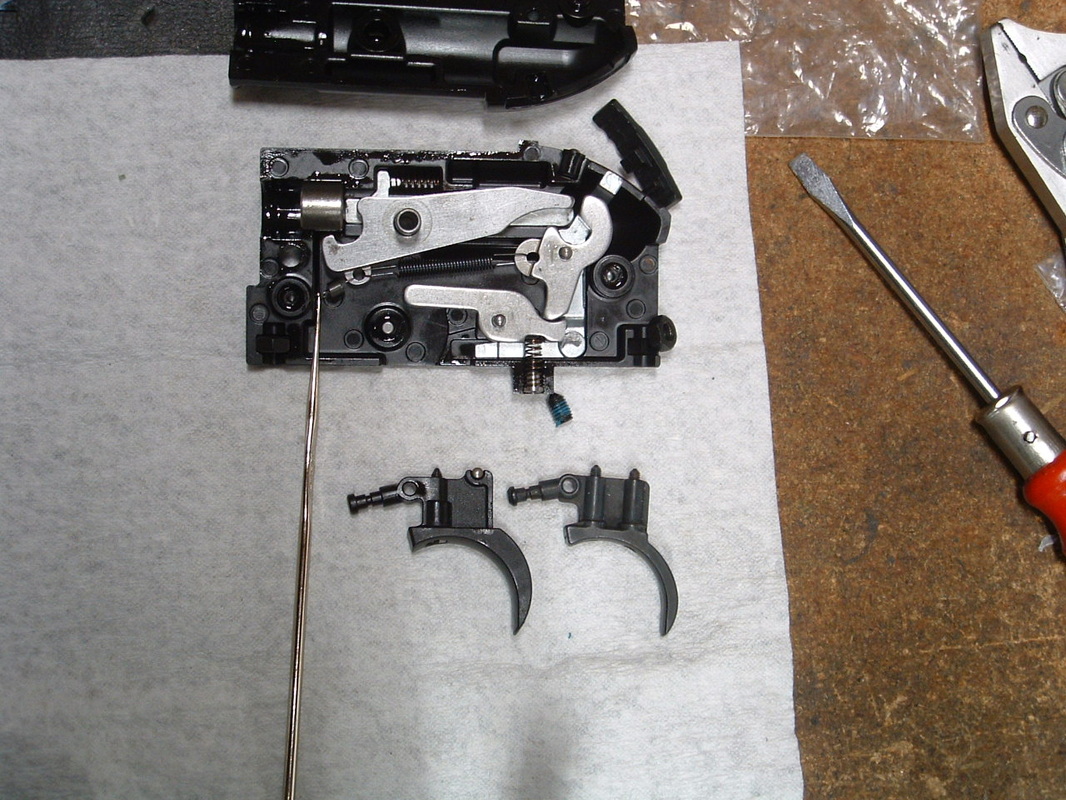

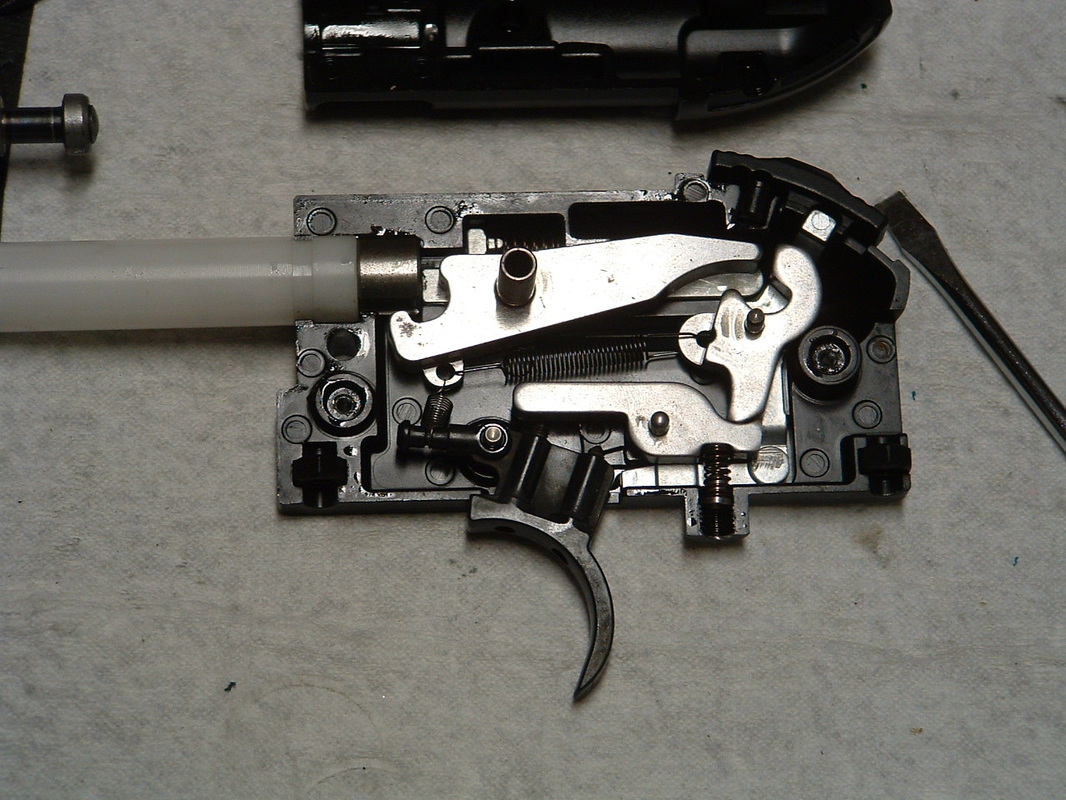

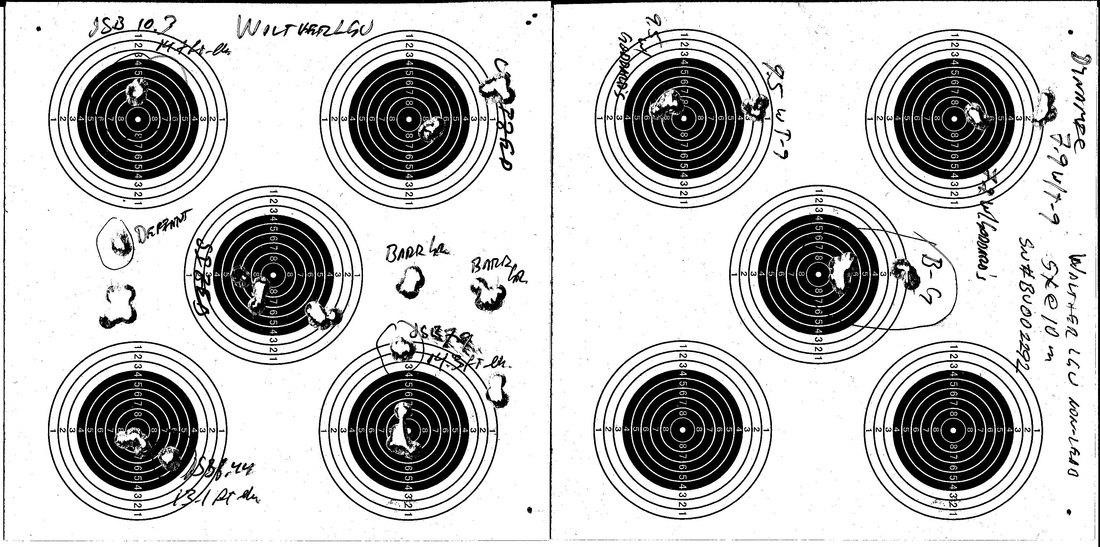

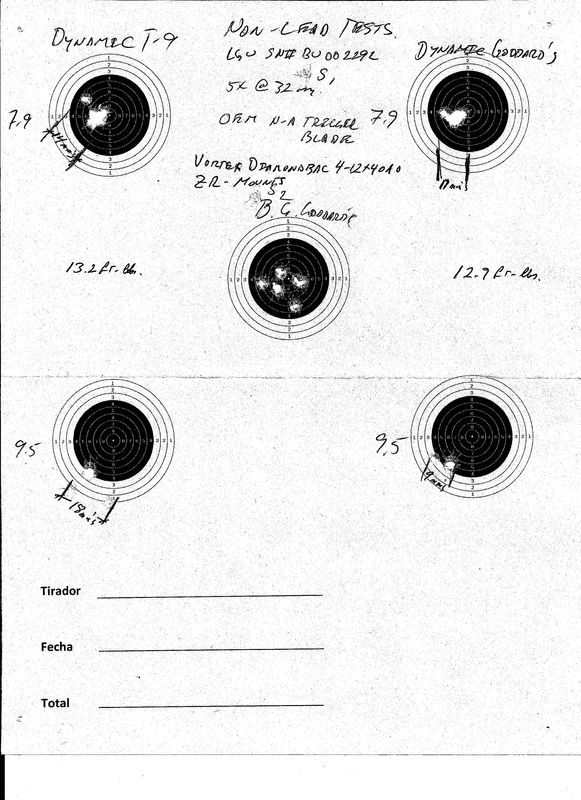

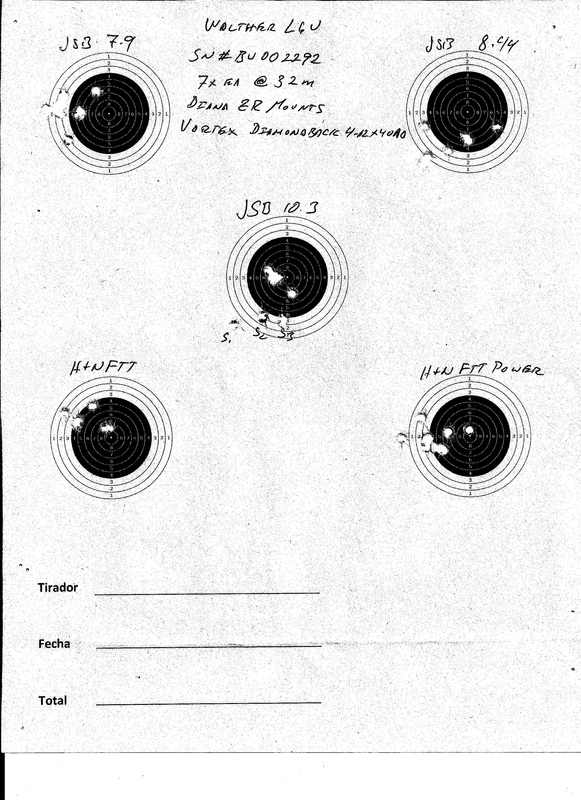

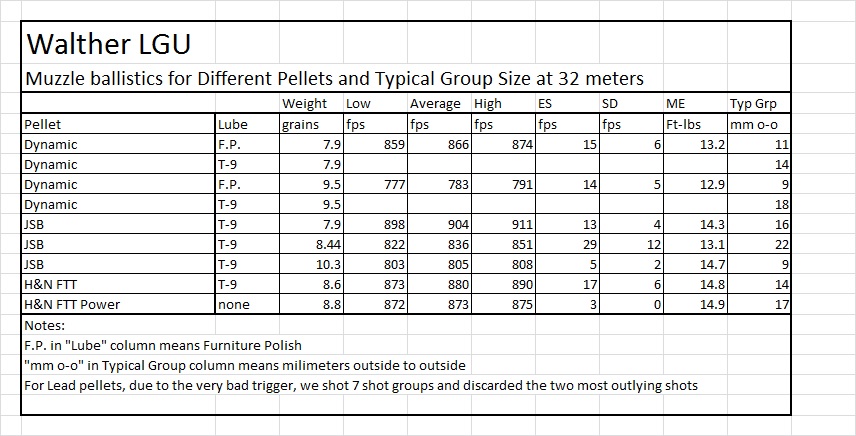

But that was not the full extent of his discoveries. He had tested the Maccari and the Vortek kits that would fit this gun and came up with an interesting proposal:

To use the HW77 25mm's kit

Dimensions seemed to be spot on, there was no slop and only a hollow section of the trigger unit needed to be filled to maintain the piston's stem alignment.

So we also tried that.

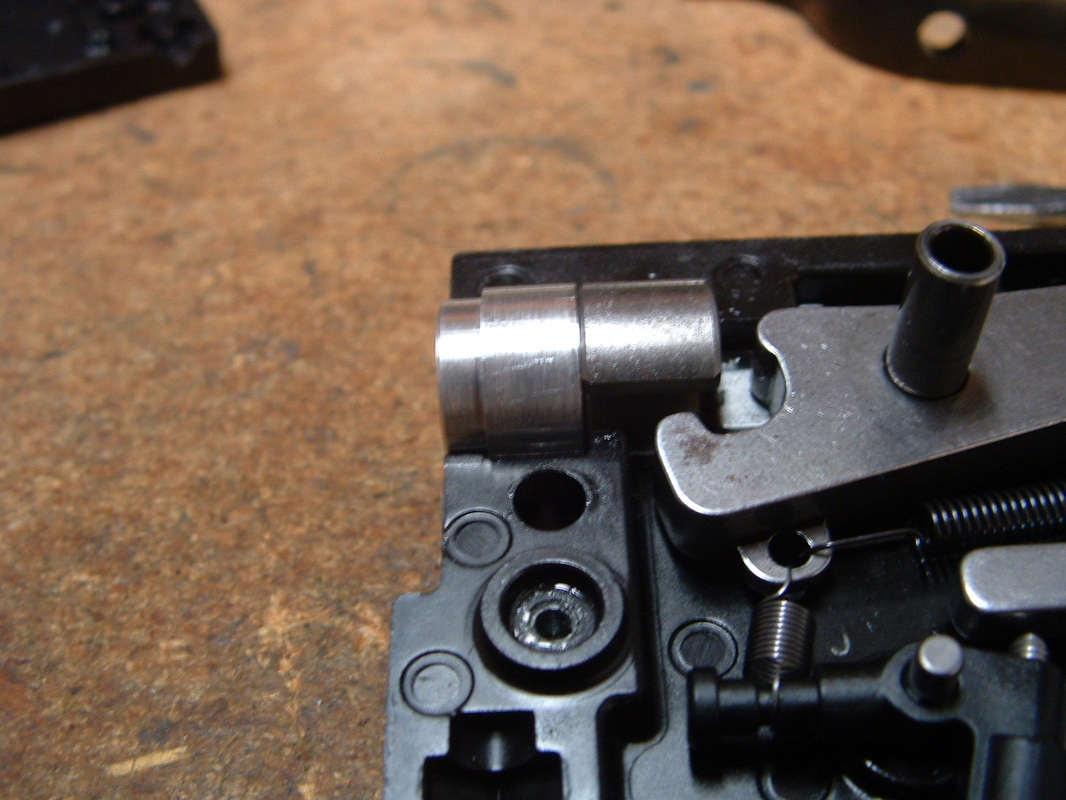

I have never had too much success turning plastic, so I turned an aluminum one:

The very obvious piston bounce of the OoB shot cycle was gone. The "thud" was sudden, quick, indubitable.

Very pleasant, indeed.

An interesting aside here is that the guns we receive in the US ALREADY have the "large" transfer port. Whatever you read on the U.K. and S.A. fora is not necessarily applicable to the guns we get here.

I've tried and tested many spring guns over the years with different tunes and from different corners of the world, but this combination is among the best I've tried. Not perfect, because the gun is slightly overpowered for WFTF shooting and the gun still recoils vertically, but it was like that before we started and now what needs to be done is to reduce the power to "legal" levels.

The recoil characteristics cannot be changed without serious changes in the weight distributions and that is changing the gun too much for my tastes.

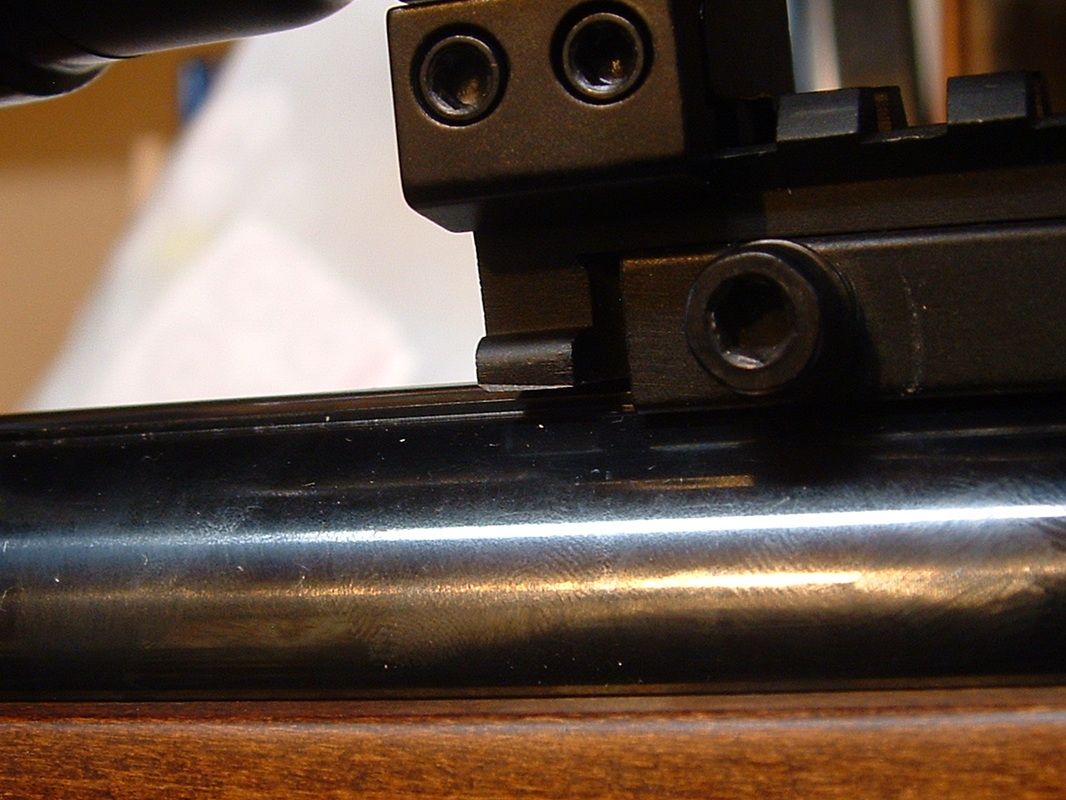

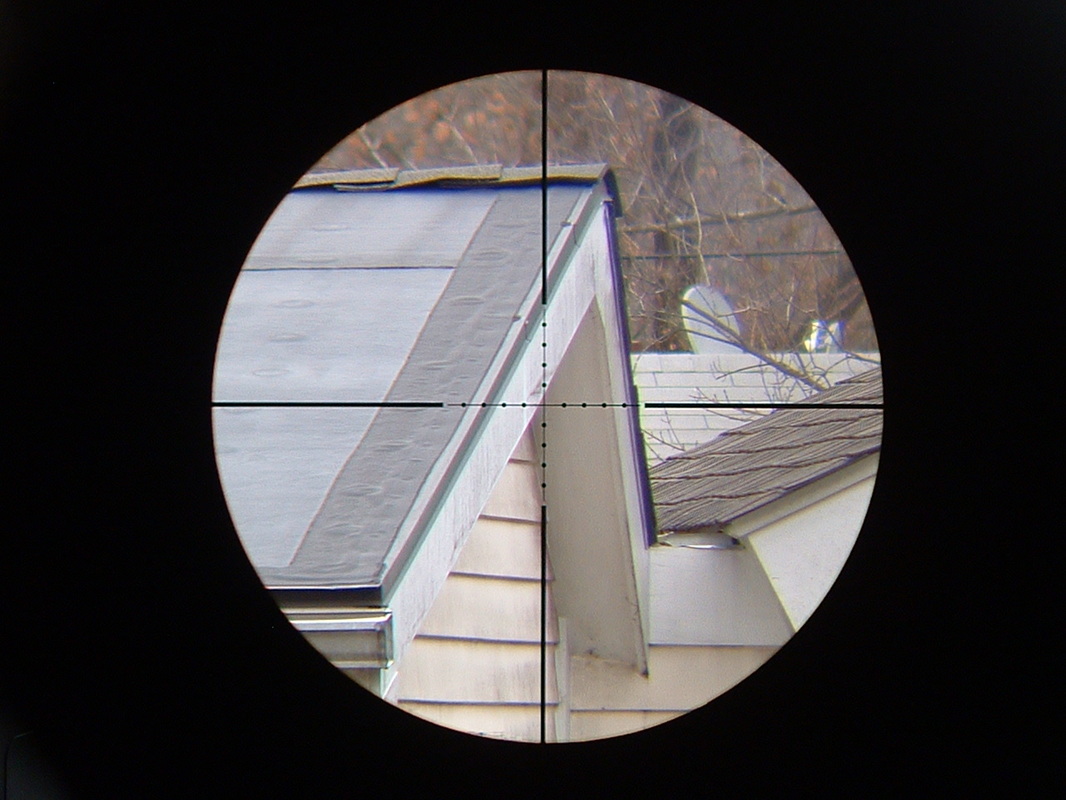

Most scopes nowadays have reasonable eye reliefs, but there are exceptions, notably the short scopes that are most useful in hunting. In this particular case the scope of interest was the Tac-Vector Optics Gladiator, a 2-12X32 FFP MD scope made for very peculiar applications but uniquely suited to airgun hunting.

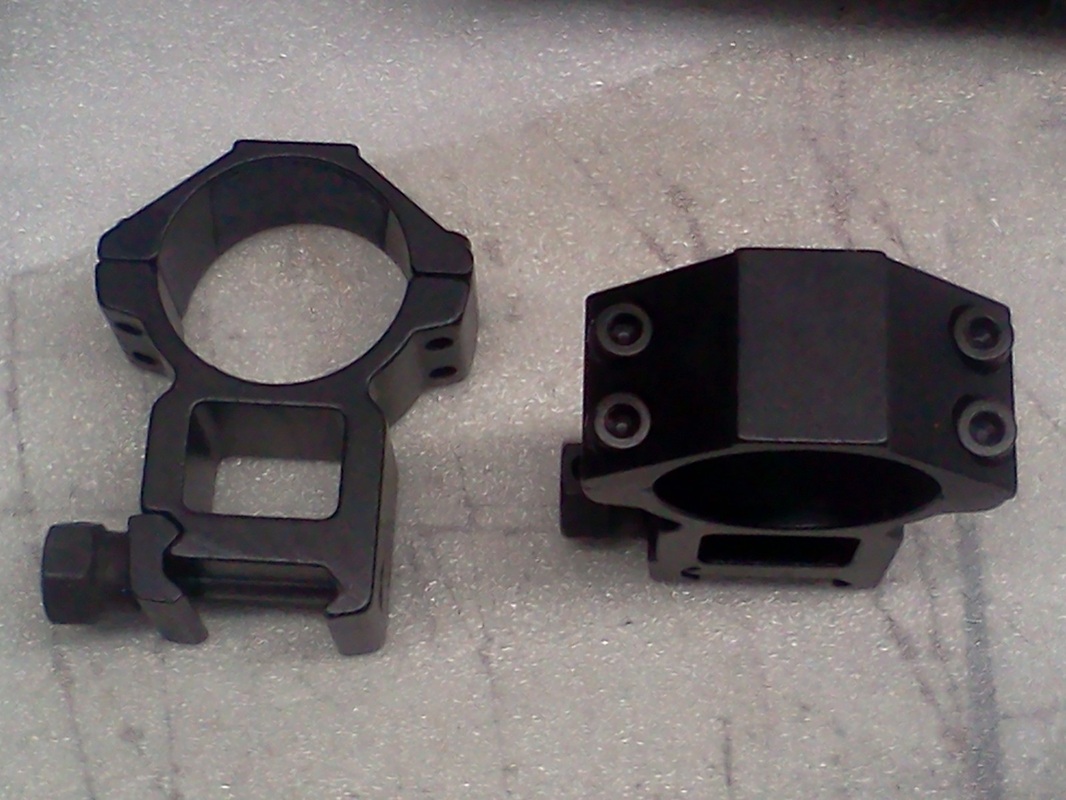

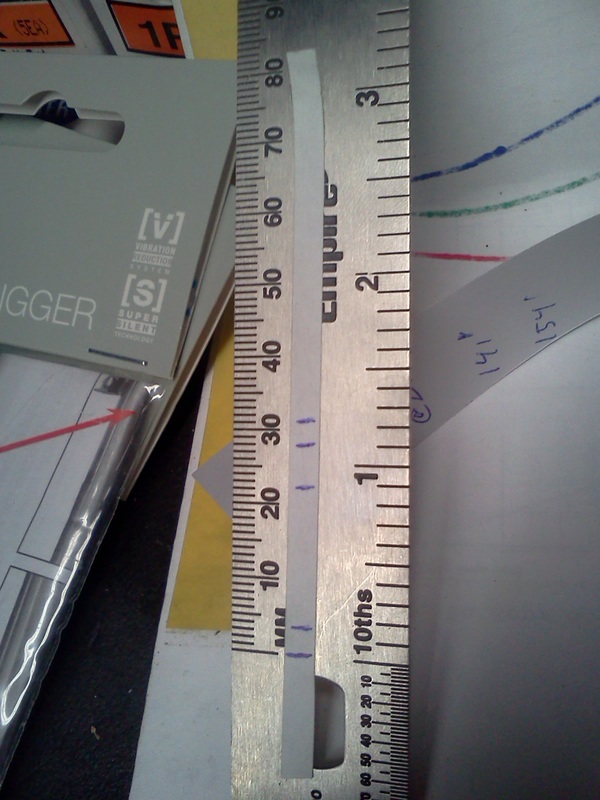

And also, the fact that the rails are cut INTO the receiver makes for a very low L.O.S. unless you use very high bases.

When you couple that with the need in a piston gun like the Walther that kicks UPWARDS, you need to get something to put everything at ease.

A good alternative is to use a rail, which also gives us a chance to correct the "droop" that is needed to keep an optically centered scope on target with a perfectly concentrically mounted barrel.

In order to "cure" both inconveniences I decided to alter an UTG rail to fit what needed to fit.

;-)

RSS Feed

RSS Feed