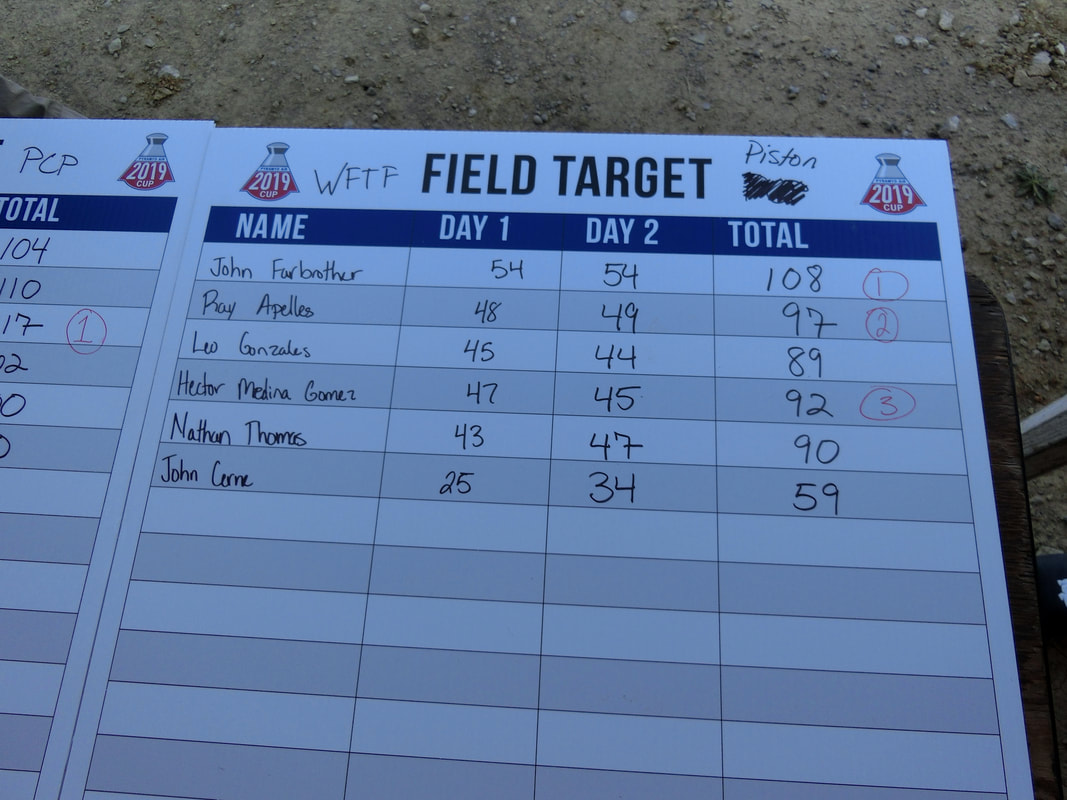

The 2019 Pyramyd Air Cup

And the reasons are simple, though not completely evident:

- It has become the largest airgun shoot in the country with about 300 entries into the three different events

- Even in just FT, it was capped at 120 shooters and the field was complete, except for some last minute drop-offs that had no "backup"/waiting list.

- It attracted more press and more media than ever before

- It has found a new venue with lots of potential

- It has started to attract formal "Teams" from the manufacturers

- It had some very high caliber international attendance (pun intended).

Of course some of this great success comes from the great prizes offered. Let's be sincere: not everyone can take an trans-Atlantic or trans-Pacific flight to shoot a few hundred pellets and then go home.

If we want the airguns sports (all of them) to grow and gain respect from the other shooting disciplines, we need to get more "professional" and the quotes are not unintentional.

I truly do NOT want ANYONE to take these statements as an endorsement of a "Savage Equipment Race". Or an endorsement of a "requirement" to offer prizes (whether cash or kind) at all regional, or national, scale matches.

On the contrary, this is a WARNING, that we (as the airgun shooters' community) will start treading the thin red line between growing the sport, and spoiling the sport.

And everyone will have different opinions and sensibilities. That is OK, we may be a great bunch, but no one has said that, individually, we are not opinionated, EVER! LOL!

To be able to put the discussion front and center is necessary at all levels, whether it is AAFTA, WRAB/ASA, or a nascent 100 yards Airgun Benchrest (if you want to call it 'extreme', or not, is up to you), is absolutely essential.

So, you, my dear readers, have now a role to play:

Write to the regulating boards of your choice and let them know how you feel.

Club reps will have to write to AAFTA to express what they feel about FT

Members will have to write to WRAB/ASA to express what they feel about 100 yards BR

Shooters will have to write to Pyramyd Air to express what they feel about the Gunslynger

So, with that out of the way and without trying to repeat what other great reviews of the PAC 2019 have shown or said, let me try to transmit to you what I felt and experienced during the 5 days that the competition took.

It has become evident to me that in reality, people don't read the write-up, they want to see the pictures, so I will post the pictures and shut-up, LOL!

See the whole film here. If you are pressed for time, skip to 1:14:35

;-)

Keep well and shoot straight!

RSS Feed

RSS Feed