In this entry, we will use the verb as meaning that we are returning the rifle, as much as possible, to the "as it SHOULD HAVE BEEN issued" state.

It all started quite some months ago (Pre-CoViD) when I was contacted by a fellow FT shooter asking what was the potential in using a Walther LGV to shoot FT.

Since an LGV is my "back-up" gun for serious FT, I answered that a properly setup rifle could be accurate, precise and consistent enough to place well in a competition.

After that first conversation, there was no more talk and I thought that the whole idea had been forgotten.

BUT, in the last North Carolina Classsic, I met with the friend in question and after the first day of competition, he declared: "I'm done, take the gun and make it what it can be".

So, I came back with more guns than I took! LOL!

I will not go into detail about the tear down and the way the gun works, there are other entries that deal with that:

https://www.ctcustomairguns.com/hectors-airgun-blog/a-yankee-tune-for-the-walther-lgu

https://www.ctcustomairguns.com/hectors-airgun-blog/a-yankee-tune-for-the-walther-lgu-second-version

Since the guns are identical, except for the cocking mechanism, what is said of one gun applies to both.

What was the difference this time as regards those first ventures into the LGU/LGV realm was that on this occasion I had NO IDEA of the provenance of the gun. It was an LGV Master. And I am sure it was bought in the USA, my friend purchased it "from a gentleman in PA", but that still does not justify what happened.

So, let's get into the project.

My friend is a good shooter. He is, literally, Championship material, so if he says the gun is inconsistent, I tend to believe him, but inconsistent by how much was still a question, so . . . the first thing was to put the gun through the Chrono.

Testing with JSB's 8.44 grs./ 4.52 mms, gave horrible results, in a 20 shot string the ES was 27 fps for a Low of 735 and a High of 762, for an average of 750 ± 7 fps for 10.6 ft-lbs

CLEARLY something was wrong.

On disassembly, I noticed that the previous owner had applied the "Yankee Tune" principles to the "Tee". But the gun simply refused to yield the energy promised and even some drastic spacing forward and aft, did not provide the desired results.

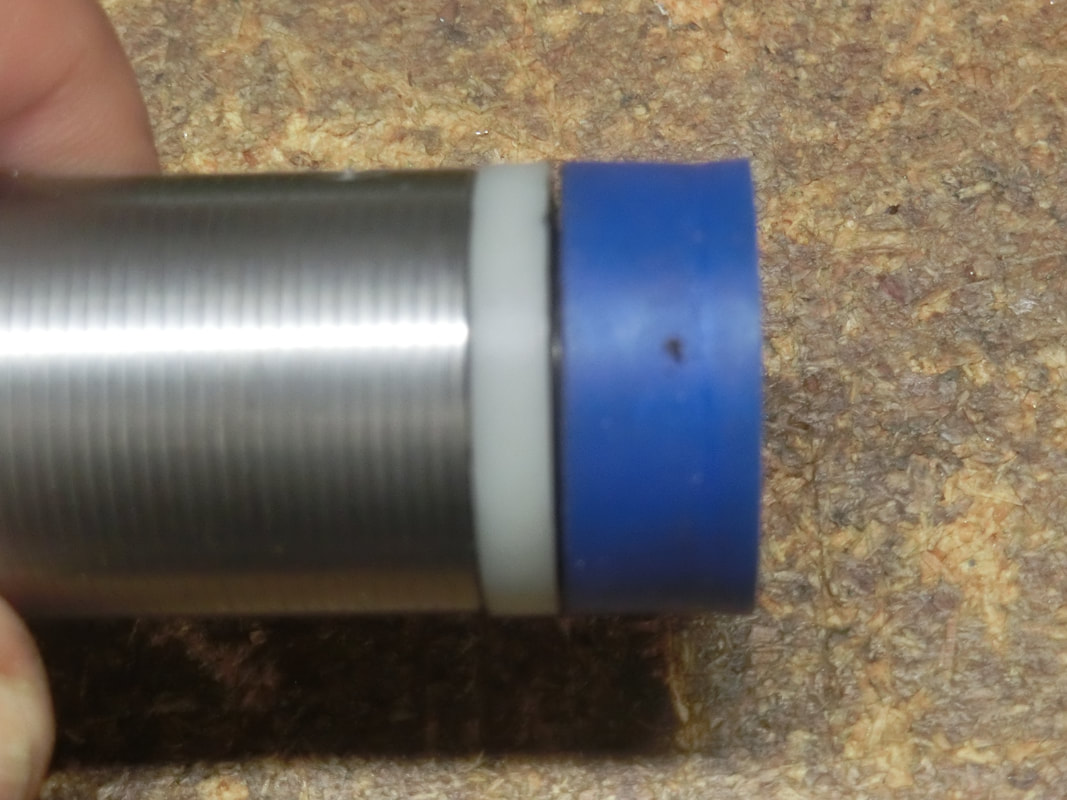

The seal wasn't either an OEM one, being blue, slimmer and shorter than the original:

Still, the job was cut out and so, I replaced all parts for OEM parts (as wished by the owner):

Observant readers will note that the OEM trigger has been replaced! Yes that is one of Eric Pianori's triggers:

https://www.ctcustomairguns.com/hectors-airgun-blog/new-super-custom-trigger-for-the-walther-lgulgv

and it is superbly adjustable, consistent and reliable.

I thought that everything had gone "just peachy" till the chrono test:

With the same JSB's, the gun clocked 741 ± 4 fps

WHAAATTT?

Uhh-Ohh! I guess that, by now, I should KNOW that if a gun gets to me, it is because others have not found a way to make it work as the owner/customer wants, or as the gun is expected to perform.

Reading over some of my notes, I remembered that at one point I had refused to change the TP of an LGV, preferring to use a much more complicated solution:

https://www.ctcustomairguns.com/hectors-airgun-blog/the-walther-lgv-pushing-the-power-limits

But the owner, in THIS case wanted to have the gun "blue-printed" and nothing is as non-OEM as a custom piston.

It had also happened that I had HAD to open a TP in some other break-barrels and I had made the tools to do it properly, so this time around, I did have the wherewithal to tackle the TP enlargement.

In brief: you need carbide drills to drill out the TP to the dimension you need/want, and also a way to remove the drilling burr from the INSIDE of the compression chamber that results from drilling from the outside in.

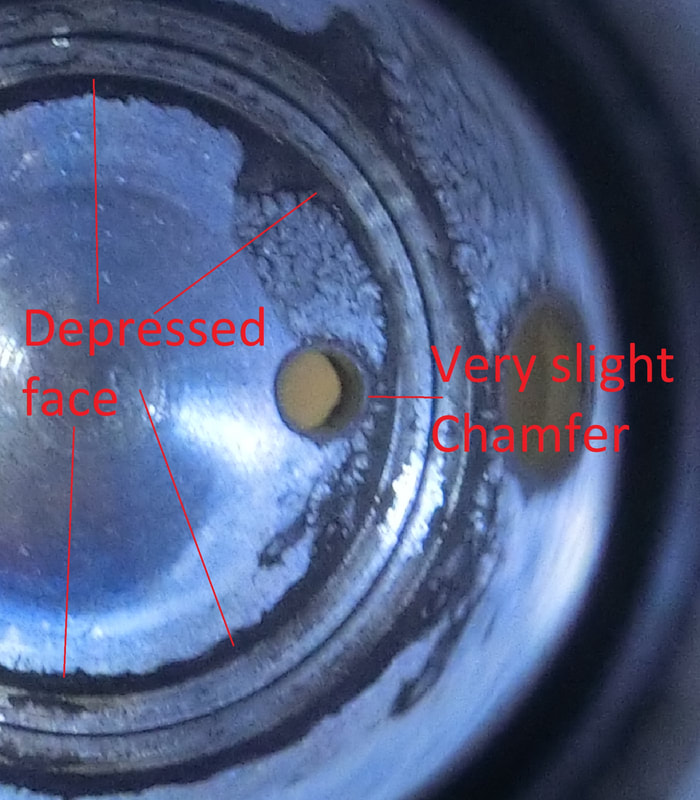

Carbide drills will cut a VERY precise and smooth hole in steel at slow speeds with mutton tallow lubrication, and that gives you control of the process, it also produces little burr on the other side of the drill, important when the "other side" is, in reality, the INSIDE of the compression chamber; where another surprise awaited us.

This gun will never achieve true "full power" because there is a "lost volume" that we cannot get rid of. A lost volume that even the excellent OEM LGV "power pulse" style seal cannot remediate.

It could be fixed with a custom piston, but then that would not be a "blue-printed" gun.

The other thing you can see in this picture (or better yet, you CANNOT see), is the normal burr from drilling the TP out from the OTHER side.

A larger drill was applied with the extension shown above and the burr removed.

Some have argued that the inside of the TP's should be "venturi'ed", IMHO, that is counterproductive because when air flows at the speed at which it flows inside these machines, a slightly turbulent flow is actually a better "lubricated" flow; a venturi style of entry would tend to reduce turbulences, which is something we do not want.

So, we only removed the burr and made sure that nothing was there to damage the seal in the second (or third) landing of the piston.

Here is a detailed look at the TP and surrounding area:

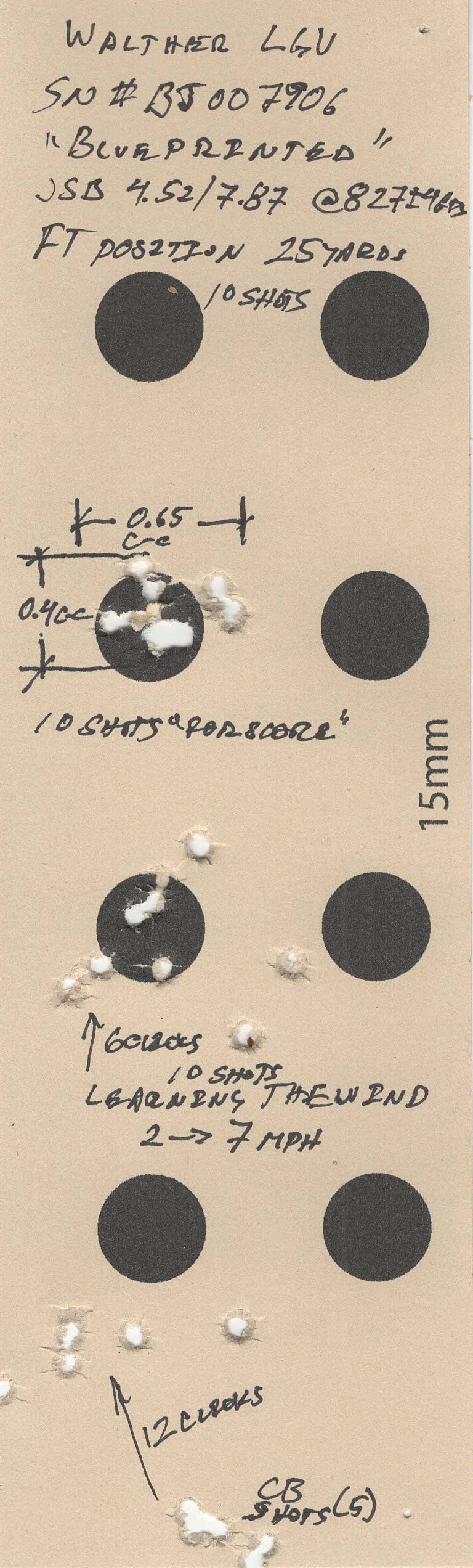

The barrel in this rifle is easily one of the best I have seen/slugged in any modern Walther, and it seems to prefer the lighter spectrum of pellets (7.9 grs), shooting them at 827 ± 4 fps for 12 ft-lbs on the dot (and the innards are still in the "running in" phase). Predictably, this rifle will settle in the 835-840 fps average and the extreme spread in MV will be reduced to single digit.

This rifle is destined to shoot AAFTA style Hunter Division, so a little over 12 ft-lbs is no problem at all.

To test this gun I installed a SIGHTRON 4-12X40 AO scope that has proven to be VERY reliable in an Accurized ZR mount:

As ALL Walthers that are made to work in the "pop gun" region, it is a bit "ringy". If this bothers the user the solution is extremely simple: just add a VERY LIGHT coating of tar to the spring. To ME, the thermal aspects of how tar behaves between a cool 50 ° F morning and a scorching 90 ° F noon are not worth it but, to each his own.

There is more to read about the LGV's in this blog, some of the entries have been superseded by newer materials and components, but I hope the readers will find them interesting:

https://www.ctcustomairguns.com/hectors-airgun-blog/swapping-the-walther-lgus-trigger

https://www.ctcustomairguns.com/hectors-airgun-blog/the-walther-lgv-a-second-look

https://www.ctcustomairguns.com/hectors-airgun-blog/the-gunsmiths-tune-part-14-full-power-walther-lgv

https://www.ctcustomairguns.com/hectors-airgun-blog/the-gunsmiths-tune-part-24-12-ft-lbs-walther-lgv

In the meantime, take care, keep well and shoot straight!

HM © May 23,2022

RSS Feed

RSS Feed