Part 4.- Epilogue

First of all, an apology. Steve and I started exchanging more and more information and I got carried away on a tangent. He was kind enough to "call me back on track". Perhaps I am too much of a scientist and love bare truth too much. So, I need to rely on good friends to make me see the forest, as I am too entangled in the trees; the delay is mine and mine alone.

What follows are my own personal observations, conclusions, and hopes of further work.

I take full responsibility for what I say or write. If someone demonstrates me that I am wrong, as I have done in the past, I will stand corrected.

Nobody's "Purfect".

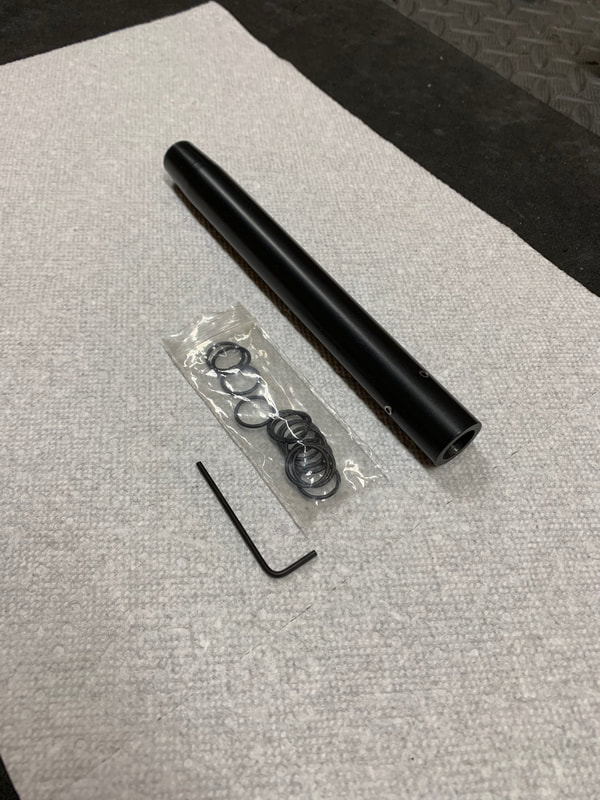

Let's re-cap: the FOCUS of this series of articles was the Harmonics Tuner (HT); a relatively simple device that allows the shooter to tune a gun to the best possible performance of a given pellet in the gun, WITHOUT altering the MV.

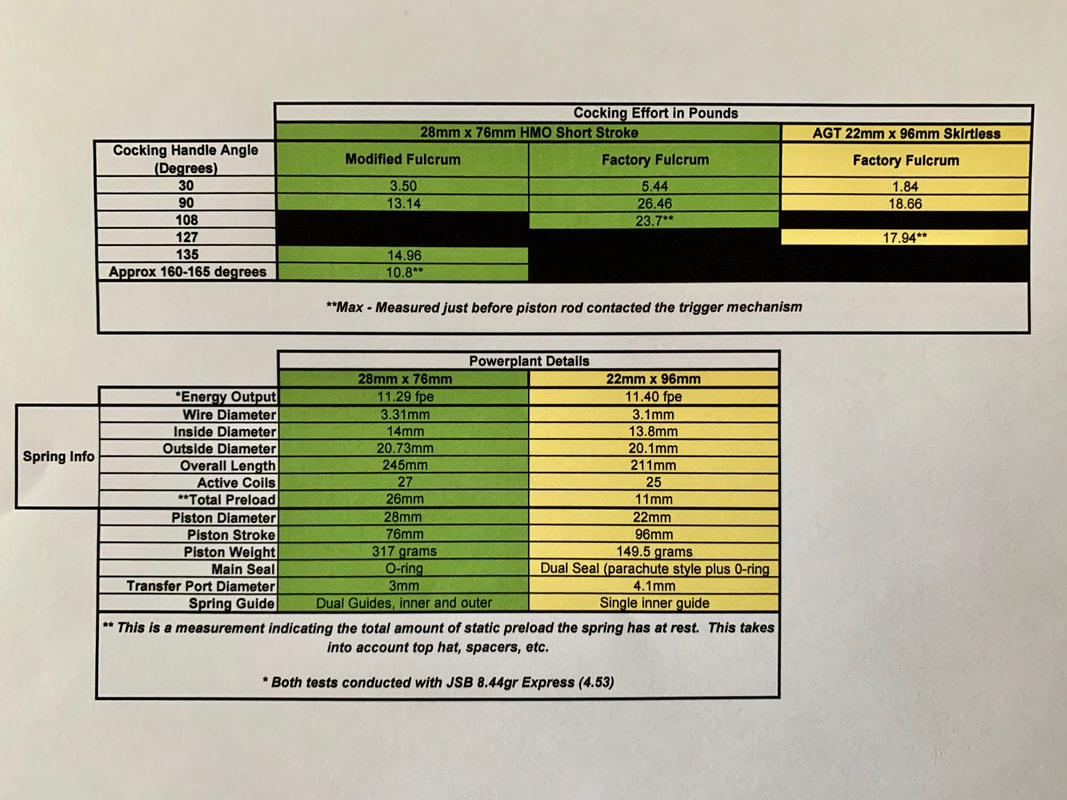

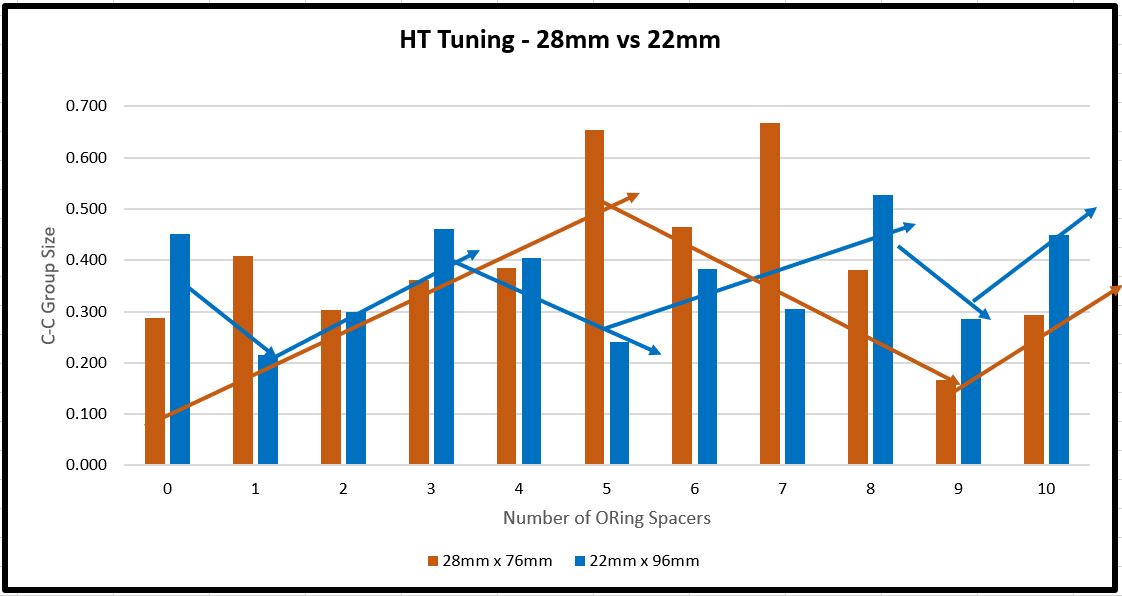

The idea was to compare the performance of the HT under two completely different powerplants to see if there was ANY measureable improvement from both, as different as they are.

As you can see from the results, there is. Smaller or larger, but there is a measureable improvement.

This is what I feel is most original.

Typical airgun tuning is done through cutting coils, change of springs/guides, change of pellets, and adding or removing washers that go from full sized spacers to paper thin power adjusters. BUT that means altering the trajectory (because MV changes) so that accuracy can be obtained.

The HT, in a way and within reasonable limits, allows us to "have our cake and eat it too"; because we can select an MV (obviously within the stability range of the pellet we want to use, and assuming that the barrel does not deeply dislike the pellet), and THEN tune to optimal accuracy and precision (depending on what we want to do with the airgun) to the best possible results within that system.

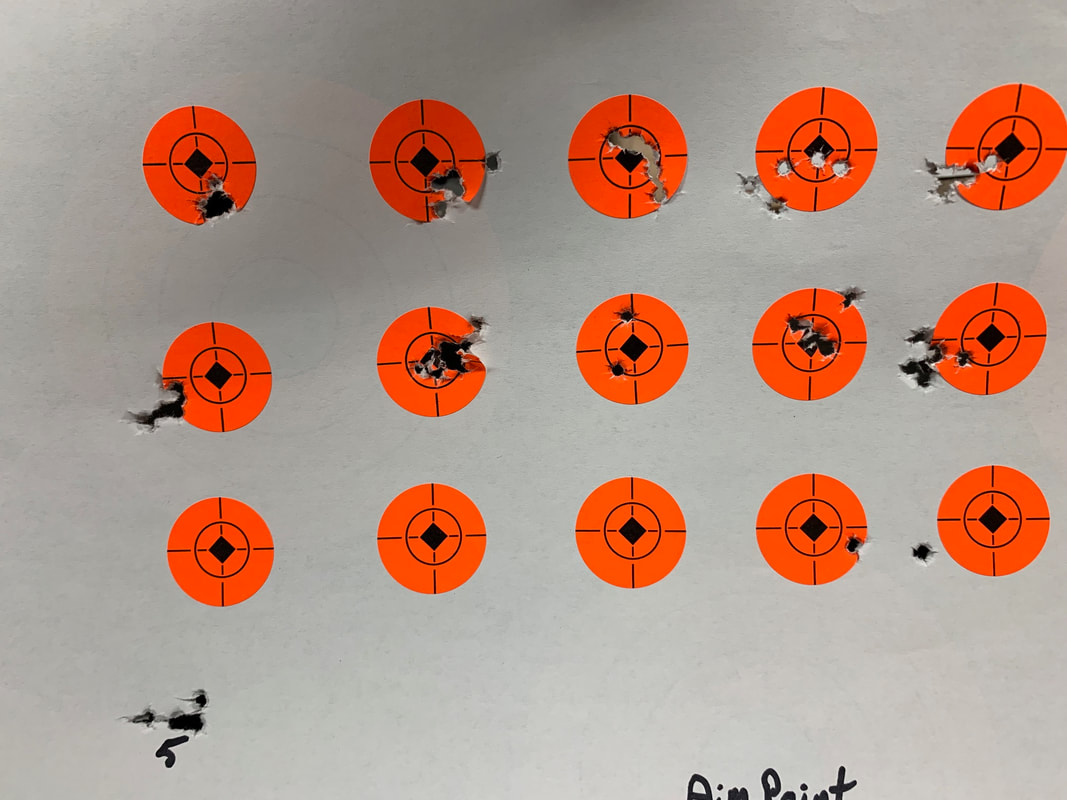

I have also received "questions" about the validity of using 5 shot groups as "data points" being that sometimes variations between groups are as large without any change, as they are when performing small changes. As limited as our tests were, we are confident that the results are reproducible in any individual's airgun, as long as the proper procedures are followed.

The RESULTS for individual guns may be different (as is normal with most aspects in airgunning), but everyone can find an "optimum spot" for harmonics tuning.

That is part of the essence of the beast.

So, having clarified all that, let's get going

I have found that in life, BALANCE is a useful concept. You need a Work/Life Balance. You need to keep a proper Financial BALANCE. You shoot better when you exercise your BALANCE. You can see the dynamics of phenomena more clearly when you look at the BALANCE of Energy and Matter.

As a person, Engineer and Scientist then, BALANCE became my "standard" way of analyzing things, evaluating things, and making decisions. From daily spending to complex physical phenomena, everything gets analyzed as a BALANCE relationship.

I like to look in detail at what I put into an airgun, and what I get back. In this sense, the HT demonstrates that for relatively little effort (as Steve has shown), substantial changes can be obtained AT THE TARGET. No need to disassemble the gun and play with the MV.

As per Steve's data, the biggest difference between the largest and the smallest group with the different powerplants was of 2 pellet diameters in one case and 3 pellet diameters in another case (at 32 meters).

¿For an hour of shooting and testing different "degrees of separation"?, I would say it is time well spent.

Sure, as airgunners we might even finish the lot of pellets we are using in testing and re-testing and we'll need to go get another lot . . . just to start again, LOL! But the facility this device gives is an interesting addition to the "airsenal" of tools that airgunners have.

As of this year, the HT will be offered by DIANA in the "New Version" of the DIANA 54 as was launched at SHOT Show 2020

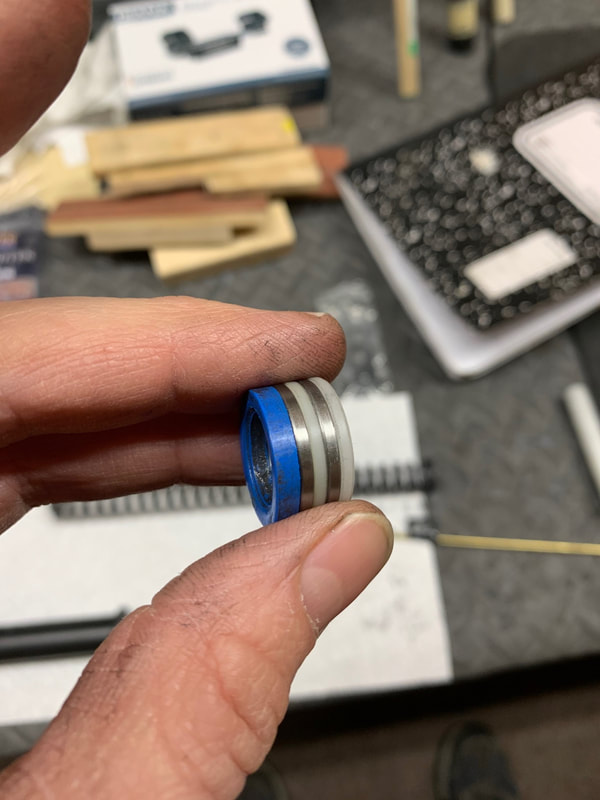

It will be a model designed for the 54, as opposed to the 56 that Steve tested so, much shorter and made of aluminum.

We'll probably call it the "HPM" for High Performance Muzzleweight ;-)

We are working on making the HPM available as an after market part for ALL 54's (as usual, in good DIANA tradition, it will be fully compatible with all previous editions of the 54, though the T01's may need a little gunsmithing).

I am told that the stock will be available in several colors and that also more traditional Beech (and perhaps some Walnut) stocks will be made available. It all depends on the wholesalers, so if you are interested, write to your favourite wholesaler to request some attention to the point of your interest.

Just to give you an advance taste:

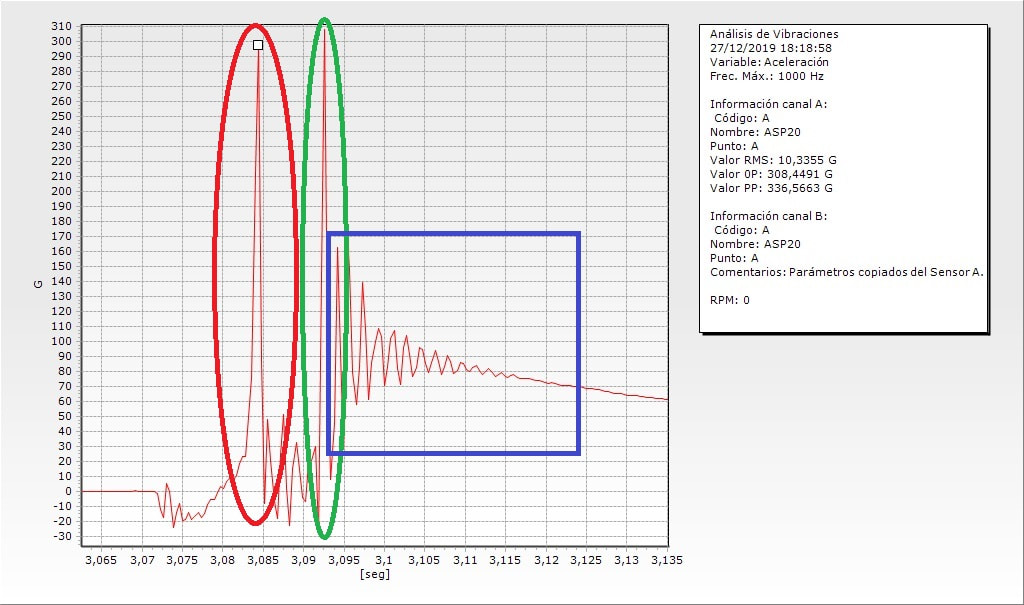

The curve above belongs to an ASP 20

You can clearly see that the first acceleration spike (red oval) is where the piston reaches the end of the air compression run, and that a few msecs later (green oval) there is an even greater "slam" BUT, the human senses cannot detect it.

You can also see the 70 g's force vibrations developing during the time of the pellet in the barrel (-20 to +50 g's for 7 msecs, though the dwell time of the pellet in the barrel is shorter).

It takes relatively sophisticated instruments to detect and measure them, not only in magnitude, but also in time. The chart also shows a good, long decaying vibration pattern (blue square).

And all this from a gas spring gun that has been reported as a "smooth shooter" and excellent at bench rest.

¡Surprise!

Anyway, it will be fun to actually make the real behaviour of the shot cycle evident for different airguns. And to see what works and what does not work, independent of what shooters "feel".

Conclusions:

The HT is a device that has been tested and proven in different power plant designs and has proven its value.

DIANA will include it in the next " edition" of D54 rifles.

There are still other technologies that await research; as long as there are people that are fascinated by the spring-piston airgun, whether it is a steel spring, or a gas ram, there will be things to discover and improve.

And THAT is also part of the magic of airgunning.

Again, I need to thank Steve for his excellent participation and impeccable work. It has been a great pleasure working with him on this.

And also thanks to our readers because without dedicated airgunners willing to read a LONG, FOUR part, entry our words would be like the sound of a tree that falls in the middle of an empty forest . . .

Keep well and shoot straight!

HM

RSS Feed

RSS Feed