Does more mass in a springer air rifle result in better accuracy?

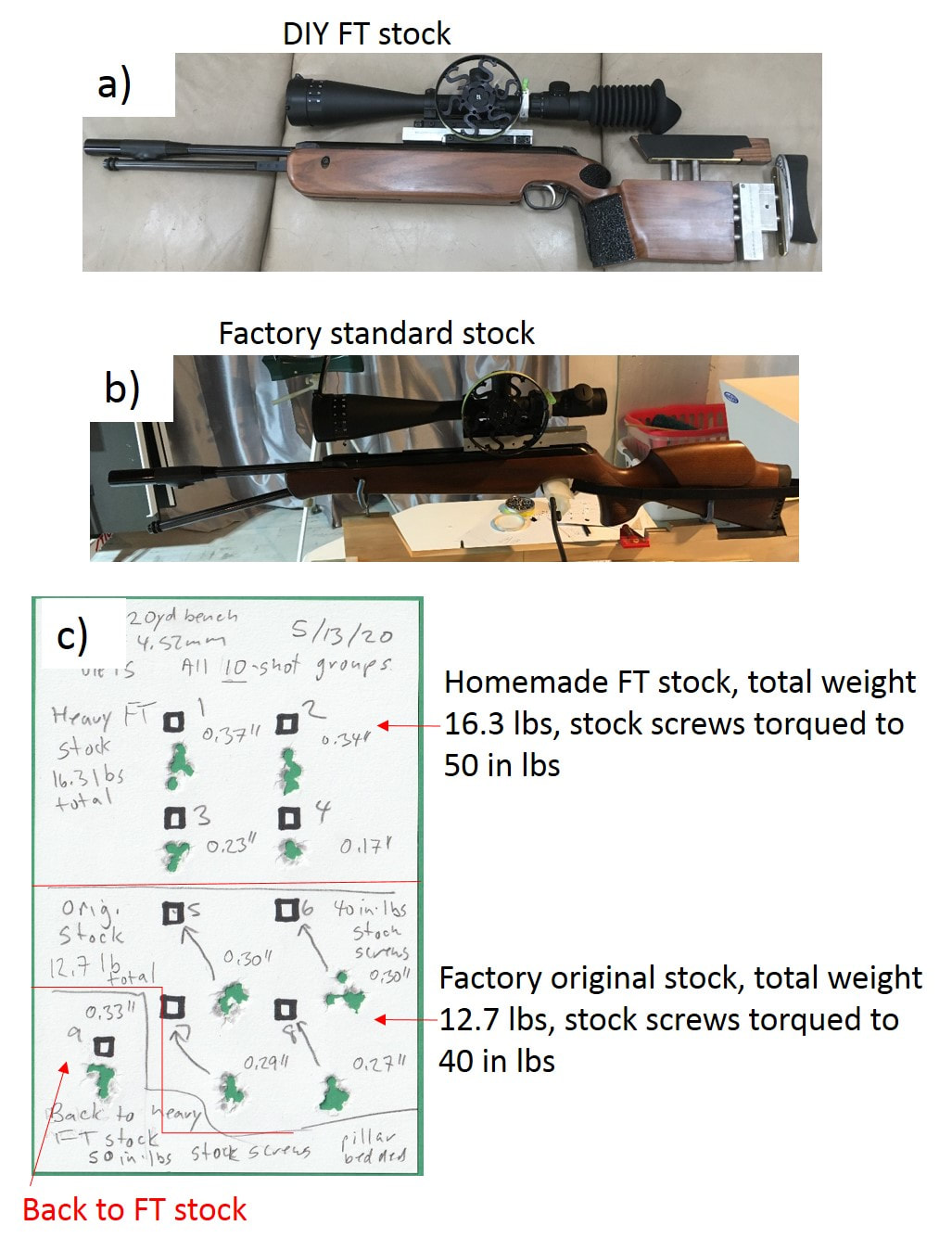

Changing the mass in my LGU was easy; I just switched from the homemade heavy FT stock to the original factory stock. The total weight with the FT stock is 16.3 lbs while the total weight with the factory stock is 12.7 lbs. The LGU is bedded in the FT stock with bedding compound and aluminum pillars, so that may help with day-to-day consistency compared to the wood-bedded factory stock.

Also, the beefier FT stock is a bit easier to hold on the sandbags. Despite these advantages, I think that the main difference is just the difference in overall weight.

Figure 6.1 shows the LGU in the a) FT stock and b) the factory stock.

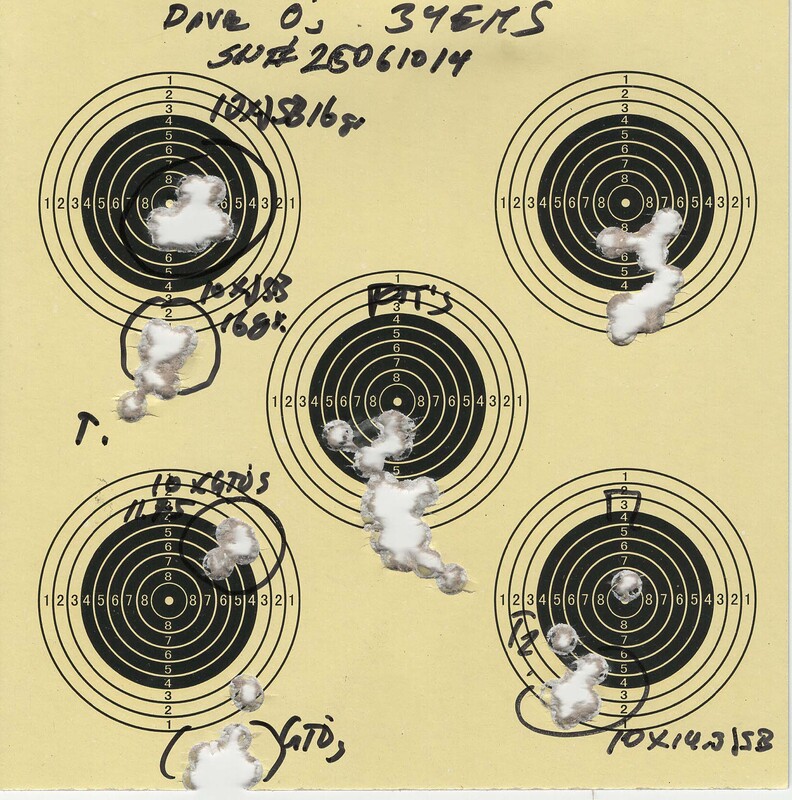

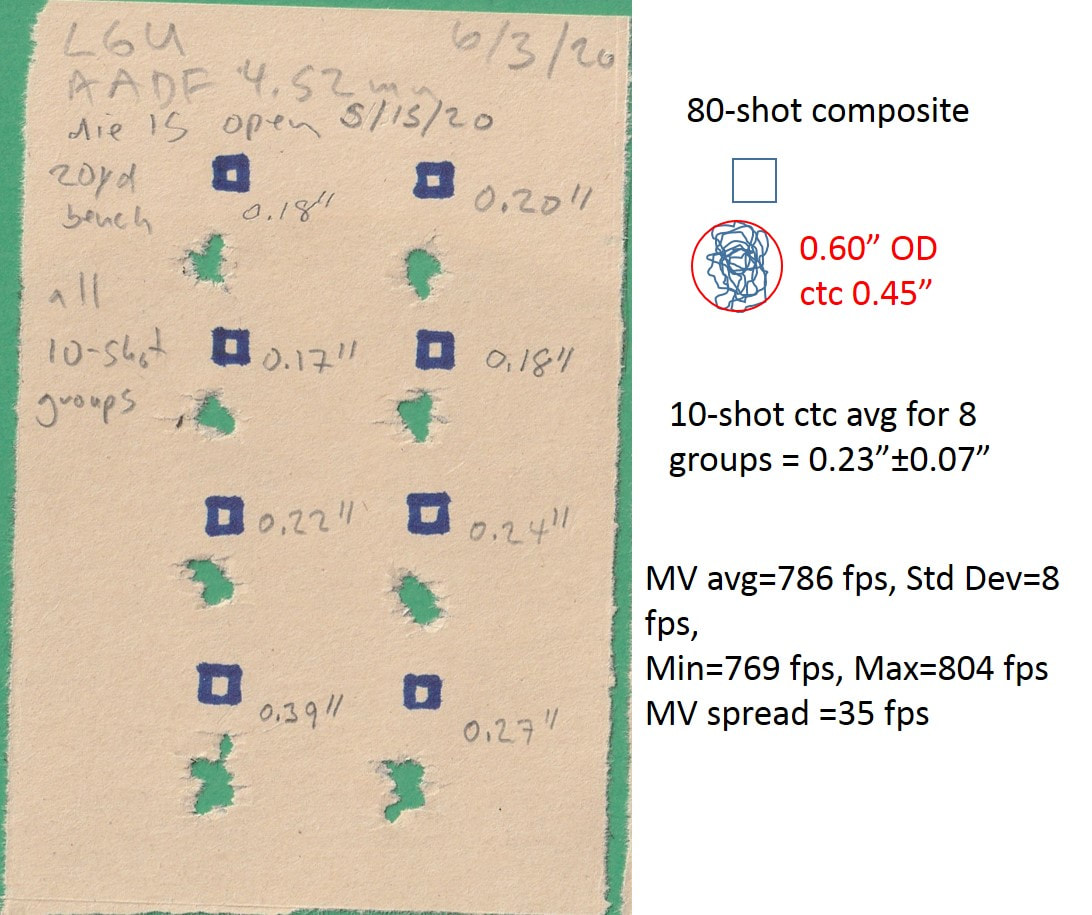

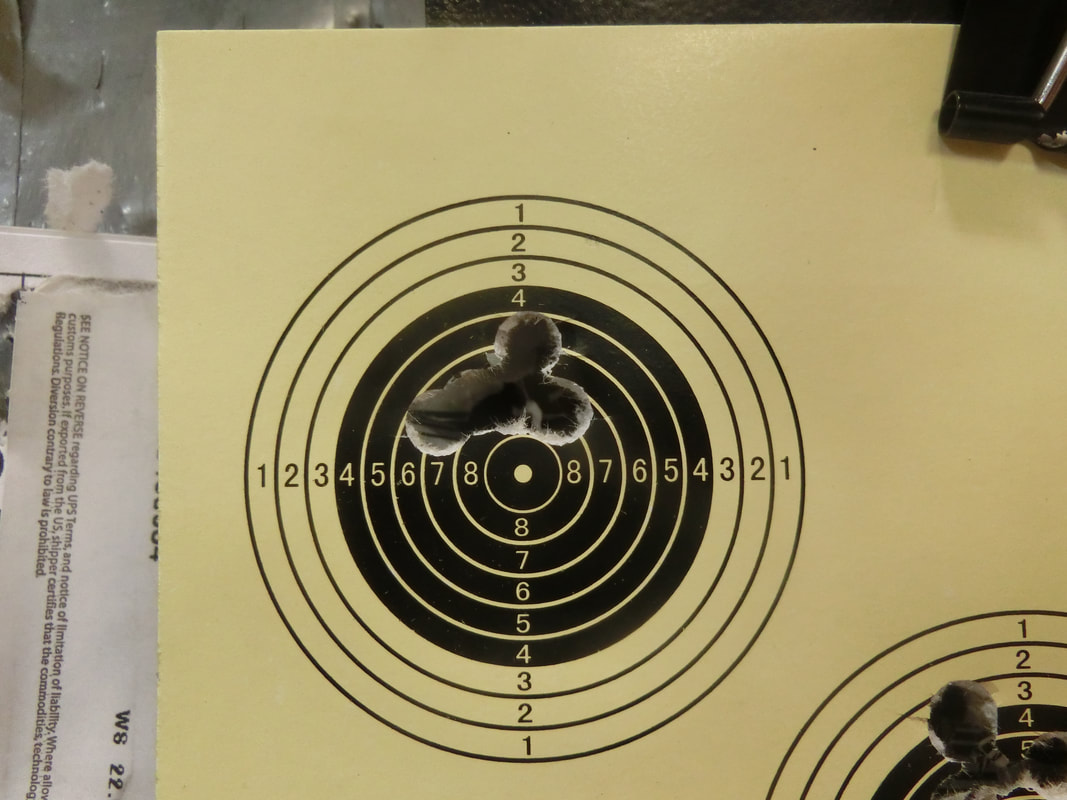

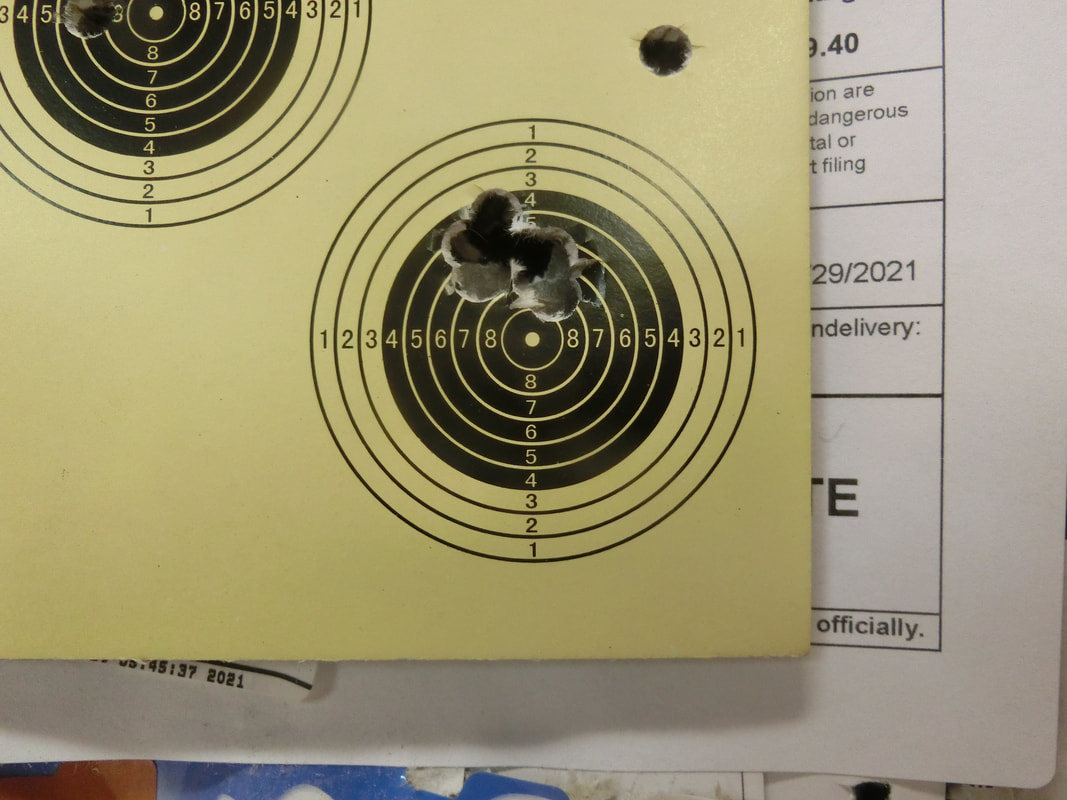

The four 10-shot groups at the top of the target card in Fig. 6.1c) were made using the heavy FT stock while the four 10-shot groups at the bottom of the target card in Fig. 6.1c) were made using the factory stock. I went back to the FT stock for the 10-shot group at the very bottom of the target card. The groups weren’t great on that day and I’m not sure what was causing the vertical stringing. The main point is that the groups shot with the heavy FT stock were very close to those shot with the lighter stock. It’s interesting that the lighter stock caused a POI shift down and to the right. It’s very reassuring the POI returned to the same place when I put the LGU back into the FT stock for the target at the very bottom of Fig. 6.1c). The average ctc distance for four 10-shot groups using the FT stock was 0.28”±0.09” while the average ctc distance for four 10-shot groups using the factory stock was 0.29”±0.01”.

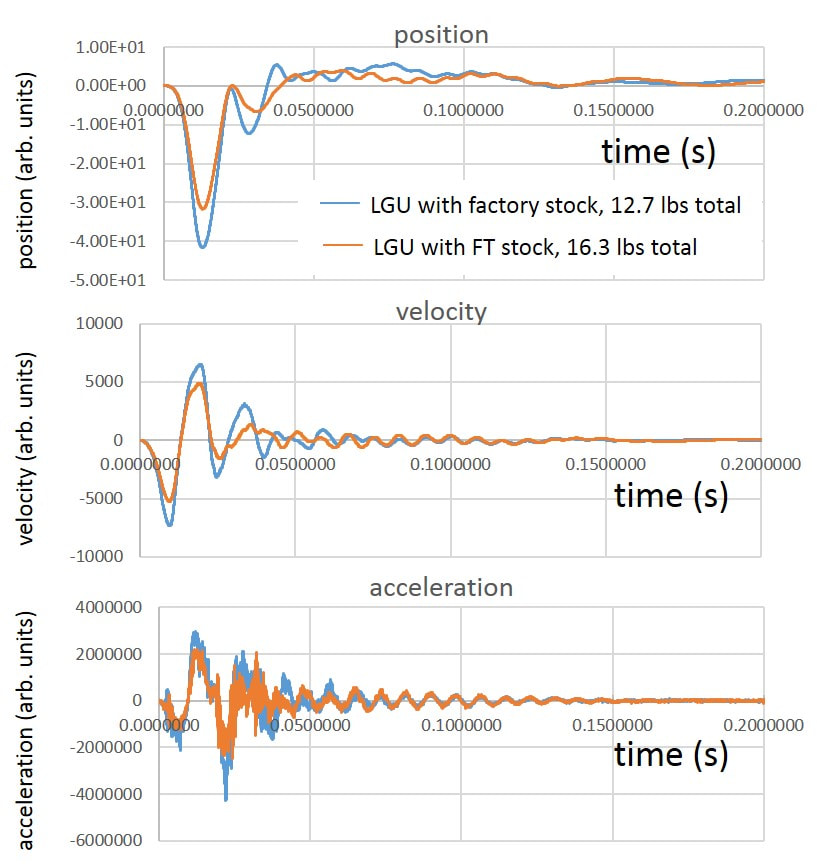

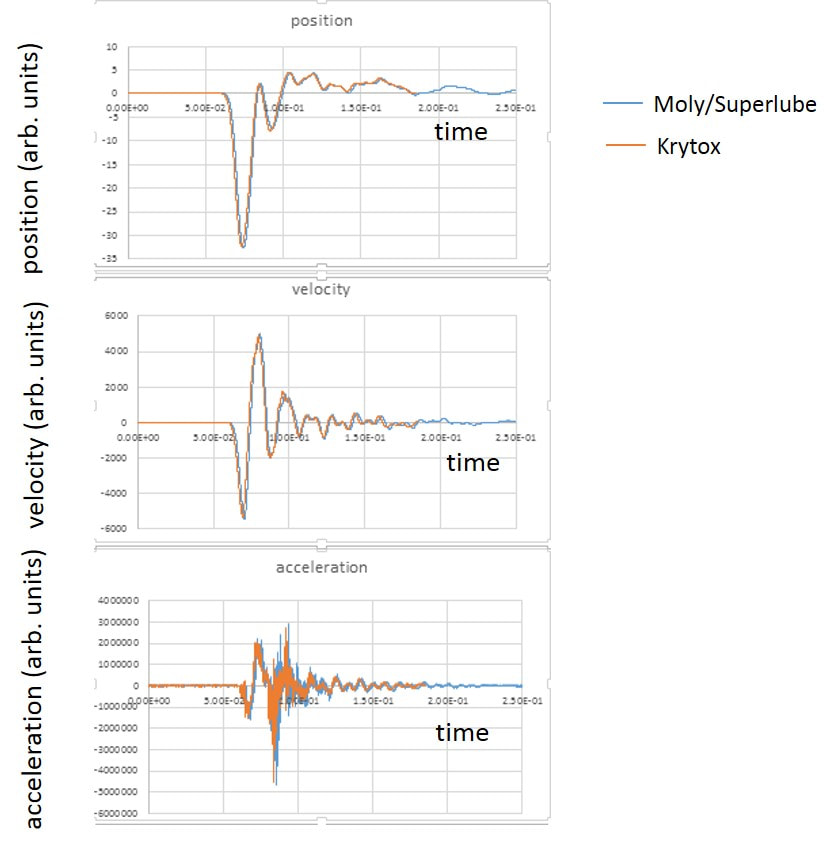

At longer times, the recoil traces come back together to be almost exactly on top of each other! One might expect the recoil dynamics to be slowed by the extra mass, but except for the second peak in the velocity, there don’t appear to be any clear shifts in time. It’s also interesting that the piston bounce time (when the velocity goes to zero and the rifle stops its rearward motion for the first time) is the same for both cases.”

RSS Feed

RSS Feed