A new breed of Break-Barrel Piston rifle

During the long hours of talks and idea sharing, we developed a respect and friendship that I am glad to be able to say that has survived the changing circumstances of life.

In subsequent years, we attended several IWA's and PAC's and our long drives to and from those events were usually spent brainstorming about the products and the markets.

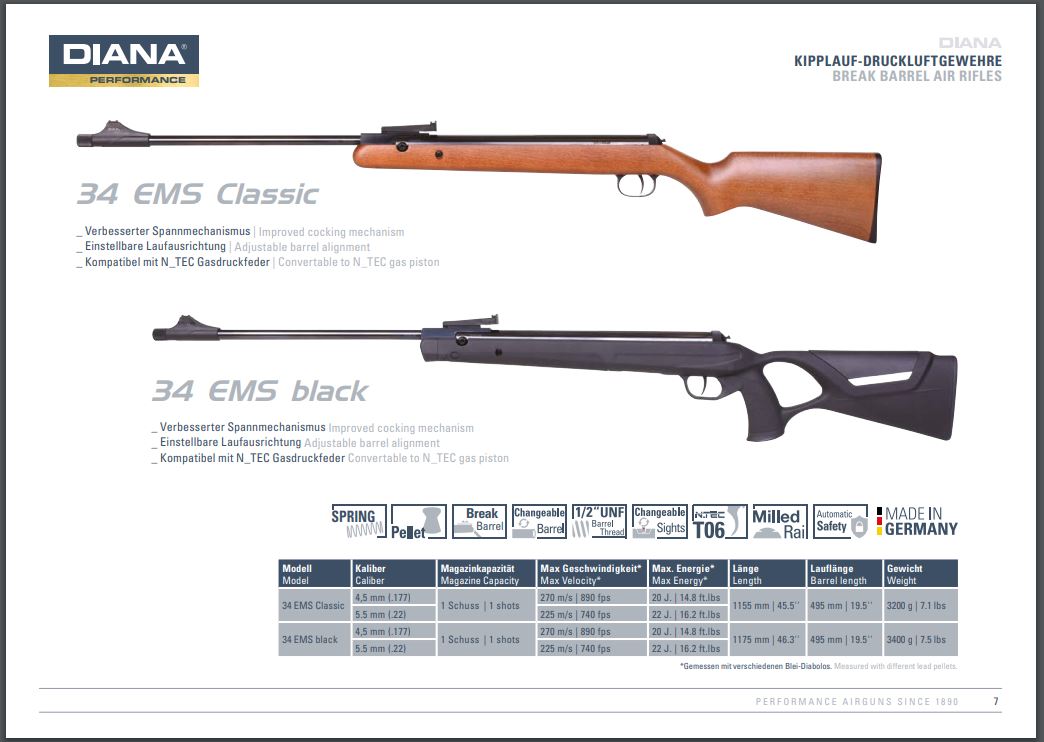

About 2018, when we drove from Maryland to Ohio together, we started discussing in earnest what the EMS COULD mean to the shooters. Before that, it had been mainly a manufacturing simplification system, where the products could be built using common parts and only some parts would differentiate the versions.

Through our conversations, Tobias saw the value that the system could bring to the market; specifically, the US market that has a long tradition of "home tinkering" and enjoys a freedom not granted to citizens of other countries to CREATE our own rifles.

And so the "Easy Manufacturing System" became the "Easy Modular System" with a focus more towards the user than to the maker.

Given the HUGE opportunity that designing a new platform brought, we looked at every detail and every nook and cranny of the rifle, from the sights to the butt plate.

And when we were almost ready to release the first pre-production steps (first one series of 10 rifles, then a series of a 100), to then go into production at full pace, CoViD struck.

This disease/pandemic has brought different responses from different countries. MOST have opted to limit people's mobility and contact, some have opted to do nothing beyond putting the responsibility in the citizen's shoulders. Others started with a lenient attitude only to go into panic when hospitals filled overnight.

But in all aspects, it has been mostly "social distancing" what has prevailed.

In a production environment, "social distancing" carries a lot of collateral effects.

Things don't get transferred as fast and as completely as when there is face to face contact.

Things take, at least, twice as long (if not four times as long).

There are more errors and more problems that could have been solved, but were not, because people are not REALLY working together.

All our plans to release the whole suite of parts and accessories simultaneously with the guns have gone out the window. Though SOME parts are ALREADY available. And the reason is simple:

EMS builds onto the excellent results of the NTec series by using the NTec piston and trigger block; and then enhancing the architecture of the gun completely.

There are three "reviews" of the EMS currently published:

https://hardairmagazine.com/reviews/ham-exclusive-first-diana-34-ems-test-review/

https://www.airgunsofarizona.com/blog/2021/02/theres-a-surprise-at-aoa-the-new-diana-34-ems.html

https://airghandi.de/en/diana-34-ems-air-rifle-my-test-and-review/

This last review has a video (in German), that is quite understandable even if you do not speak German.

As good as the reviews are from a consumer perspective, there is a LOT more going on and I will try to touch on some points that seem to me to be of importance, yet ignored by the reviews in favour of velocity numbers and pellet tests. IF there is enough interest, perhaps we can post a complete analysis of the differences and the real advantages of the new architecture.

A typical complaint in the fora, usually by people who are "keyboard shooters" more than the real thing, has been that the parts to upgrade the guns are not yet available, but that is not completely true, and in this blog entry we will look into an upgrade that CAN be performed with a part in the current list of spares from DIANA.

From Steel to Gas Spring

But, let's get started:

The "Classic" version of the stock is the one currently available. IF you compare it to an old 34 "Classic" you will see that this stock is slightly more slender, and that the comb is a bit higher

This puts the recoil more in line with the center/shoulder point of contact to the butt plate, and so, the shootability of the gun gains because there is less "jump" to the gun when the piston is released.

This is something that has already been identified by HAM's technical reviewer, my friend Eric Brewer.

With dual fiber optic pipes, it is adjustable for both windage and elevation and the screws have re-assuring "clicks" that tell you that the screws will not move on their own, as well as allowing to count the variation you are incorporating in the LOS.

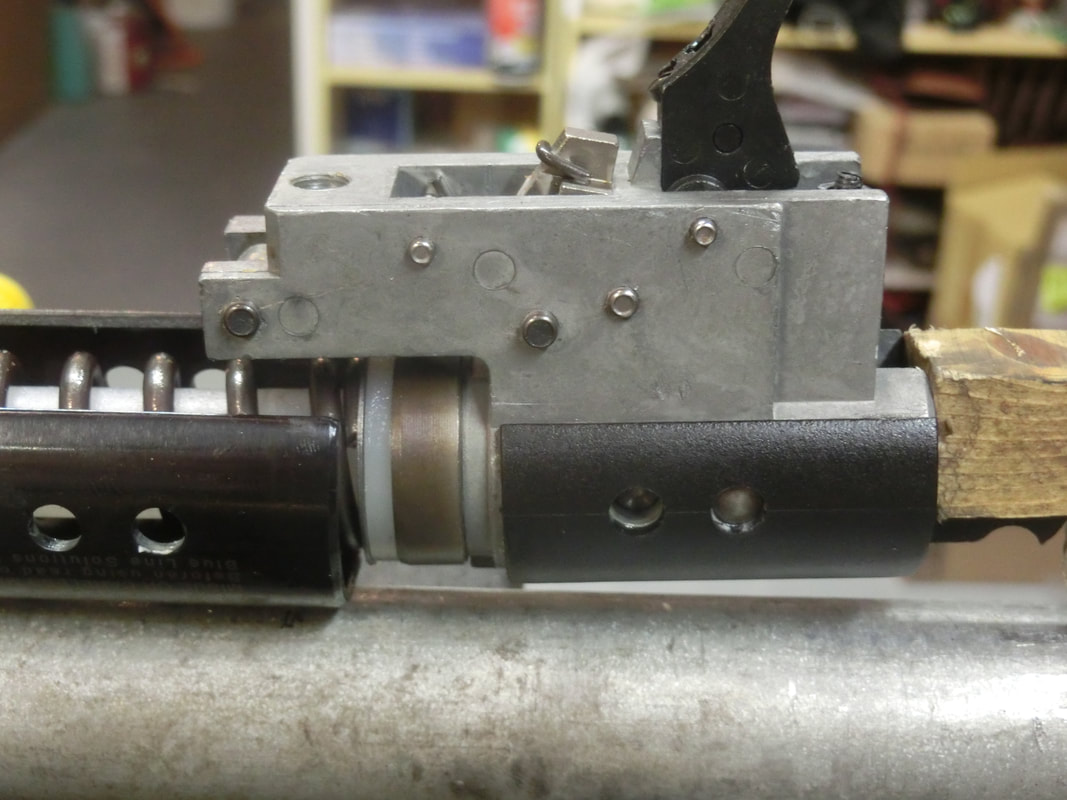

You can also appreciate here the fork adjustment screw and nut, they both take a 5 mm's Allen wrench. Screw is on the left hand side, nut is on the right, and underneath are real nord-loc washers. IF your forks are "Too tight" shoot the gun at least 100 shots before deciding to losen the arrangement. In any case, you do not need to take the stock out to adjust the breech-block to fork tension.

Another thing to note is that all 34 EMS's are issued with the Serial Number in TWO locations: at the fork as you can see from the picture, but also in the barrel, so that people can know if a gun is keeping its original barrel or not.

For the savvy shooter, this allows some degree of "tuning" because the tension between stock and action can be regulated in a solid manner. This could also be done with the "old" 34, but now the degree of adjustment is one degree of freedom better.

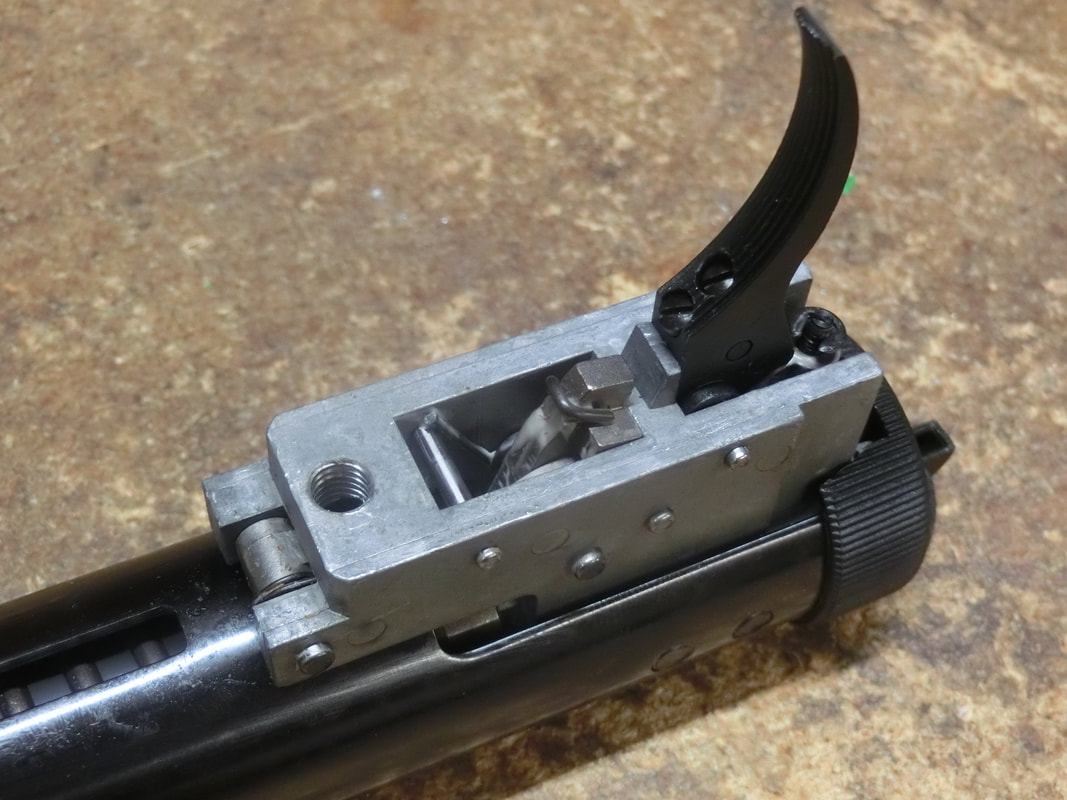

The T06Ntec trigger is an interference trigger. Meaning that there is a ramp that rises and locks into the slot at the skirt of the piston. When the trigger is released, the ramp "falls" out of the way.

It is an incredibly fast trigger, especially useful for offhand shots.

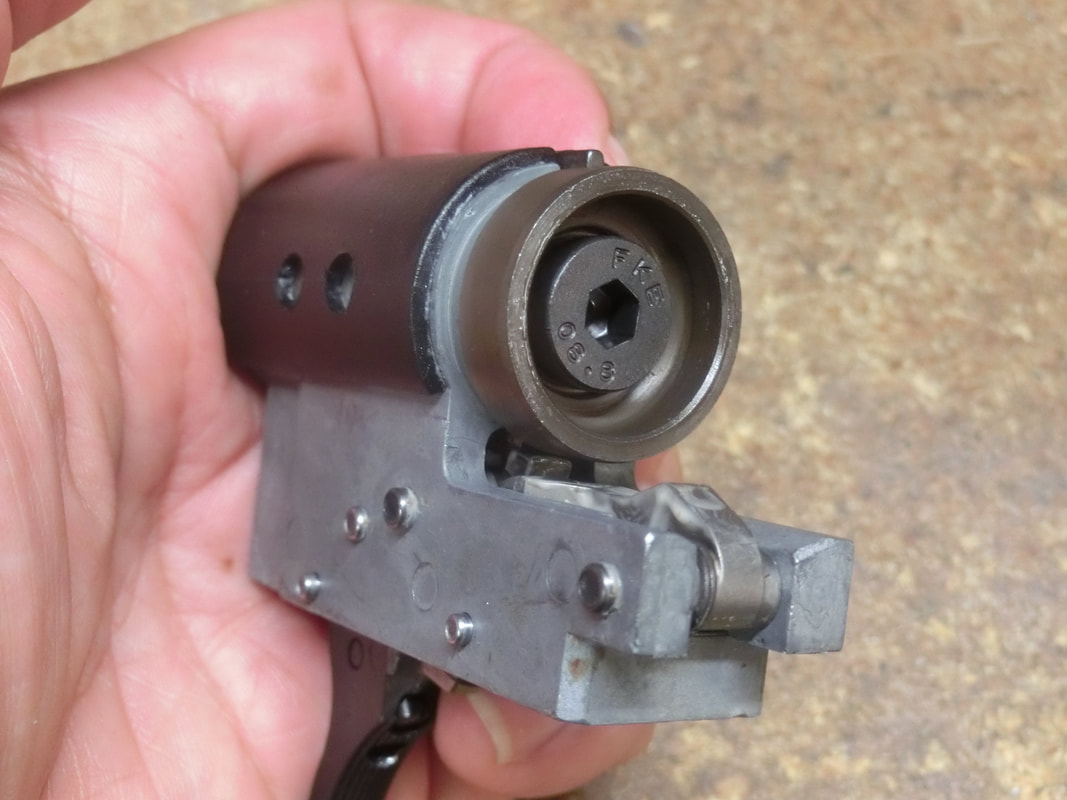

Removing the whole spring lets you access the front guide.

The front guide is a solid piece of steel, and adds considerable weight to the piston. Once that guide is removed the gun's power plant is "skewed" towards lighter pellets.

This front guide can be replaced with an Anti-Bounce unit, but that is a custom project we may talk about in a future entry.

In the trigger you will find a simple allen headed screw that needs to be removed.

I would STRONGLY recommend using Vibra Tite by applying to the thread and then letting it dry. THEN assembling the NTec gas spring to the T06NTec trigger block.

Assemble the stock to the gun, taking care to glue some flat washers to the bottom of the recesses so as to protect the wood from the star washer chewing the stock to death.

And test.

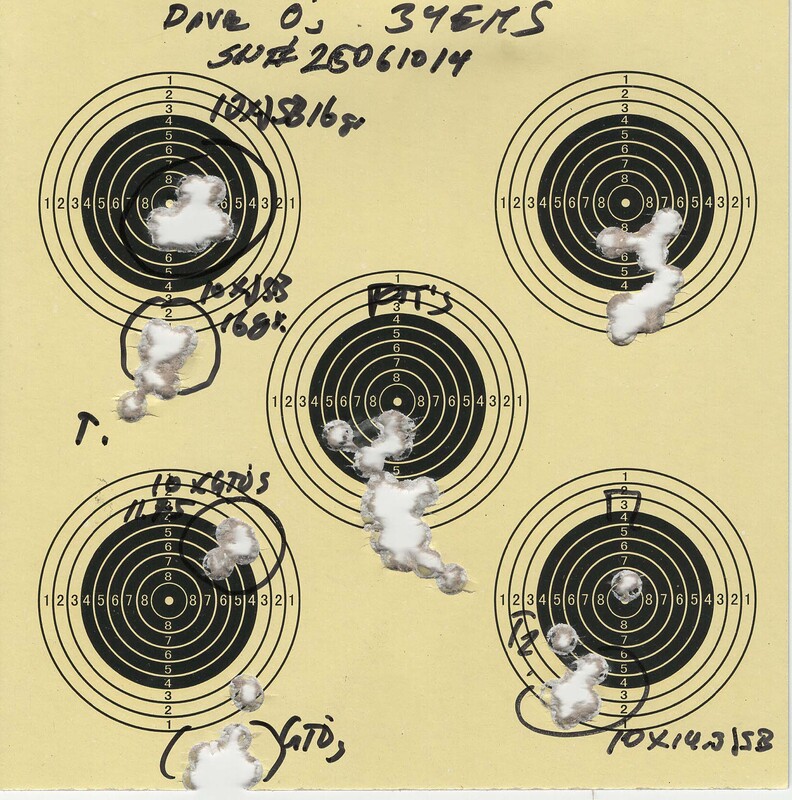

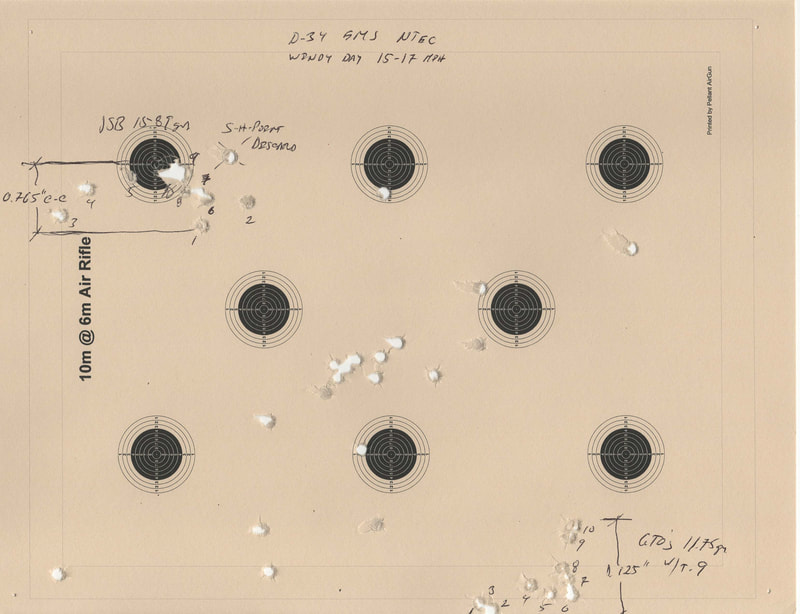

Testing different pellets at short range will give you an idea of which pellets to try at long range.

The Crosman, FTT's, and other pellets simply did not "jive" with this barrel. Perhaps in the future, once the full 500 shots "running in" has been accomplished things may change a little.

The JSB's yielded 15 ft-lbs, while the GTO's yielded upwards of 17 ft-lbs

This rifle is now equipped with a fixed shroud that still allows the tuning of the muzzle harmonics, so once the user defines exactly what he wants to do with the gun, some fine tuning is possible to achieve the best accuracy with the pellet he chooses.

In our tests, the length of the barrel is not as crucial to the energy delivered to the pellet as in the PCP's.

The conversion itself took all of 20 minutes to do and I think it is achievable by anyone that can change a spring or a piston seal. I do believe that it complies with the "design intent" when we set-out to make a gun that was easy to be "converted" to what each shooter wanted.

As this pandemic eases and we learn to live in the "new normal", I hope that more and more of the planned accessories and tuning elements will become available.

For the time being, I have secured 8 gas springs to do this conversion, if you are interested, drop me a line through the contact page.

Keep well and shoot straight!

HM

RSS Feed

RSS Feed