He was not happy with the 0.177" caliber as it seemed to be on the "loose" side and pellets fell when he swung the action closed.

So, we sourced a few barrels from DIANA and, while it took some time, I think the results are good.

Process is not complicated but it does require a specific order of operations.

You start by taking the action out of the stock, a simple three screw operation that we all know how to do.

Then you need to take out the rear sight and the front sight. Rear sight is no problem because the screws are visible. Just make sure that you do NOT loose the 0.5 mm's ball that creates the "clicks" in the rear sight elevation knob.

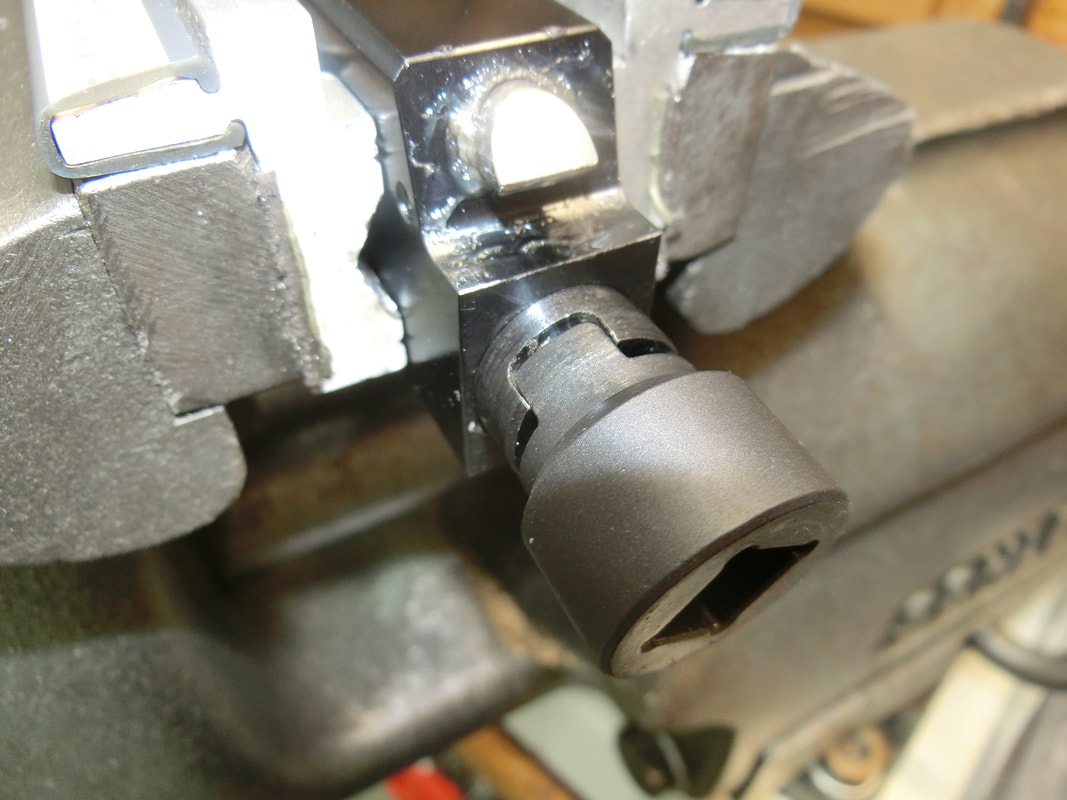

The front sight however, is a bit more tricky because under the visible "thread protector" there is a nut, and in the rear sight ramp itself, there is a grub screw:

Personally, it does not bother me so, I always work with the linkage connected.

Personally, I like to clean the barrels very well and then polish the bore and rifliig with JB bore paste.

In this picture you can see clearly, from left to right how the "exiting" pellets show less and less scratches and deformations as the process goes along:

Shards left in the bore may adhere to the next pellet and create a "vane" that will send a flyer out of the aimpoint.

This barrel was additionally re-crowned.

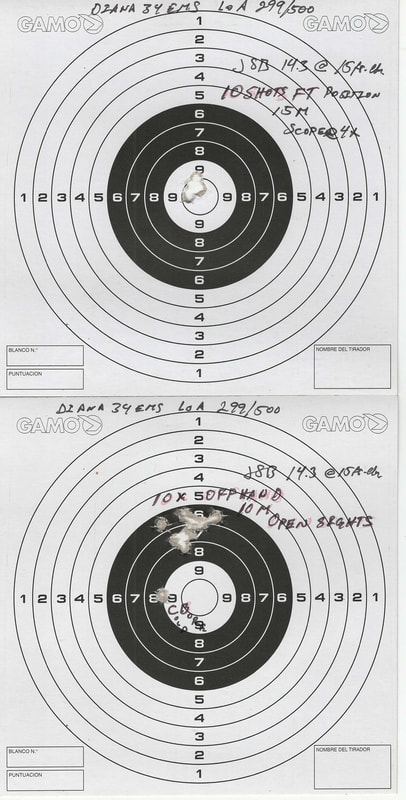

In the end, the work performed paid out.

What counts is performance at the target, and with the barrel's favorite pellets, it did quite well for a break-barrel in the 15 ft-lbs class:

I don't know how it was shooting before, but I do know that any reasonable target at normal break barrel airgun range is in danger with this rifle.

;-)

Keep well and shoot straight!

HM

RSS Feed

RSS Feed