The conversion done here was carried out by a professional gunsmith. No warranties implied, or otherwise are intended in this article. The milling operations carried are sensitive, not devoid of dangers and of a high precision nature.

Do NOT attempt this conversion if you are not completely qualified to do so.

This conversion has NOT been sanctioned by Diana nor by Mayer & Grammelspacher.

This conversion proved safe IN THE GUN that it was performed. We cannot guarantee that all other guns will receive the conversion in the same way.

Please do not ask for measurements or dimensions, Connecticut Custom Airguns cannot provide these data.

All designs and parts' shapes and dimensions are proprietary to Mayer & Grammelspacher and their Diana brand.

UUufff! That was a mouthful!

Anyway, let's start at the beginning:

Many years ago, an Argentinian designer came up with the idea that a piston airgun could be a far simpler device. So he set to work and came up with a peculiar gun where the lever moved the BARREL back. The barrel, in turn, pushed a floating piston that to its rear had a closed cavity that could be pumped up with air, or the air could be let out to reduce the energy stored in the compressed gas.

The lever then pushed forward the barrel and the loading was through a turn-cock arrangement like many old German guns.

That prototype evolved and eventually became a commercial model, BUT, as it sometimes happens in life, a pair of British subjects (we must remember they are not citizens), was also working on what they termed a "superior device". Superior in the sense that it utilized the TRADITIONAL piston airgun architecture with all its moving parts and peculiar triggers. So, in their zeal, they took the Argentinian designer to court and won the case.

I have always suspected strongly of all litigations around "inventions". Lately, the world has adopted the convention that the patent belongs to the FIRST TO PUBLISH, thereby eliminating the need to demonstrate the specific date of the "invention". Again, I dislike this because it plays into the hands of those corporations that have patent lawyers on retainer and whether they work or not, they charge a minimum monthly fee.

More and more we see all patents in our life (and death) owned by large corporations that can then jack up prices as they want (the pharmaceuticals are a perfect example)

Perhaps, coming back to the "gas-ram" invention litigation, the Falklands war was also a determining factor.

Whatever it may be, it is an undisputable fact that the Argentinians already had a "Gas-Ram" rifle in commercial production and being sold in their market when the idea was patented in the UK.

To the victor go the spoils.

Fast forward to the present day and after a little over two decades of exploitation, the patent expired.

And so, all of a sudden gas springs (different from Gas Rams) began cropping up everywhere. From the Crosman's of a few years ago to the Hatsans and Diana's of present day and interest.

DO note that HW made their own Gas Ram model under license of the Brits, whether sold as HW or as Beeman, it is the same gun.

Another thing that has evolved enormously is the science of materials. We now have materials that 25 years ago would have been unthinkable. From Titanium, steel and high strength aluminum alloys to highly complex polymers for seals we have at our disposal in economic terms things that in years past would have costed hundreds, if not thousands, of dollars and would probably have required a National Security clearance to buy.

The improvement in materials and availability of pure, dry gases has changed substantially what the old Gas Ram was.

I still remember about 17 years ago that I gifted a 0.20" cal. RX2 to my good friend Mike Pearson, airgun hunter extraordinaire.

As soon as he received it he took the pump and pumped it up to the max. Then he complained about how hard it was to cock and how inefficient the machine was.

That experience colored my perception of Gas Ram's (and gas springs, by extension) till the present.

I still fix the occasional RX-2 or HW-90, but after this experience I know that the REAL problem is that those designs and specifications are simply obsolete.

I have to admit that I tackled this project with some trepidation. The modifications made to the gun would be non-reversible, so the gun was modified forever. Something that IN GENERAL, I do not like to do. But the thirst for knowledge and the long term route that I have planned needed this first stepping stone and so we took a gun that was worth the effort.

And here comes another fact that should not surprise anyone: If you want an N-Tec gun, BUY an N-Tec gun. Between the cost of the parts, the original gun, and the labour you would end up paying TWICE what the original N-Tec equivalent gun would cost.

The only valid reason to attempt this conversion is if you have a superbly accurate 34 and you want to up the power.

Of course, it could be argued that it would easier to swap barrels, but sometimes the accuracy is also a function of how the stock fits the shooter and so, swapping barrels while expedient, reversible and economically savvy, does not resolve all the issues.

And there are no lessons learned in a purchase.

So, having explained a little of the background, let's get to the technical aspects

This is one of the virtues of the gas springs: they keep a constant pressure on the end of the stroke and do not rebound as much as the steel arrangement of individual coils that we call steel springs. By eliminating the rebound of the piston, the gun is much more efficient, specially on long transfer port models, like the 34.

The second thing that should call our attention is that Diana ships their N-Tec triggers with TWO dumb pins. And the reason is simple: some parts could get out of place and cause severe problems upon assembly.

I have found that the usage of dumb pins, while not a necessity is a desirability because it speeds the process and helps prevent problems.

Some people say that they NEVER use dumb pins in the disassembly of their guns, of course, when queried, they have to admit that sometimes guns don't get assembled at first try, and the some pieces have become damaged when they fell out of place and the gun was assembled like that.

My grandma used to say that "to those that die of their own will, death is but sweet nectar". Let everyone disassemble their guns in whichever way they like, LOL!

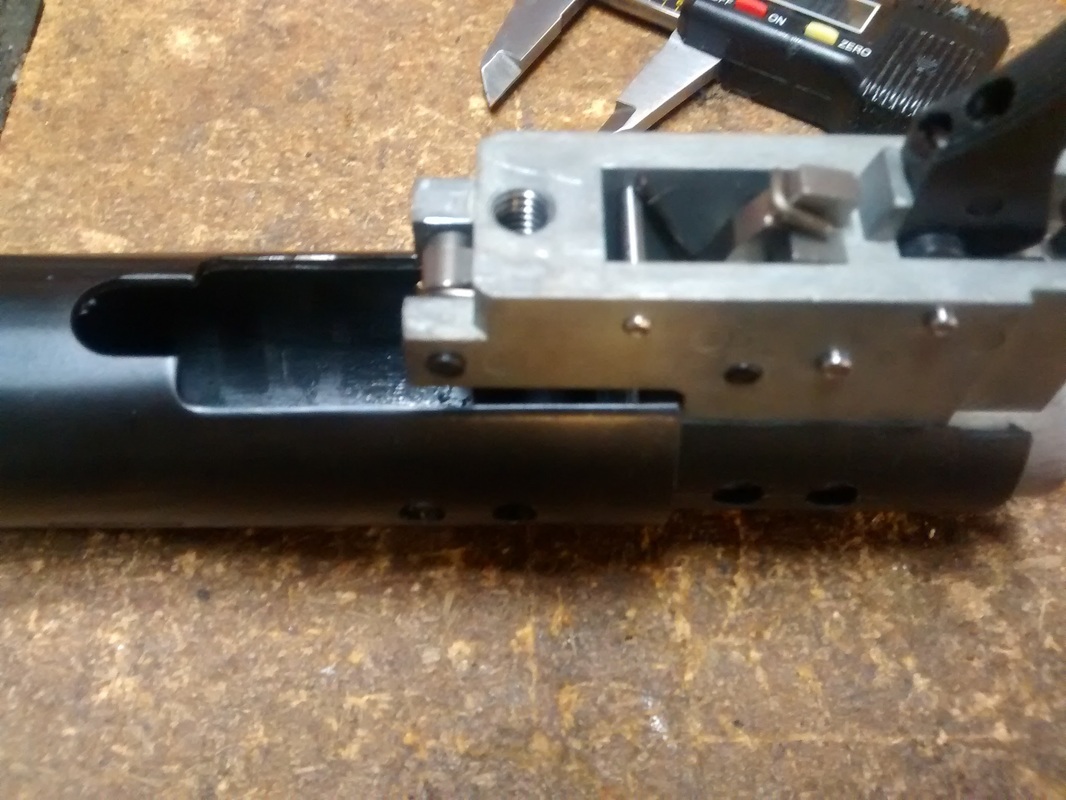

The N-Tec assembly is composed of 4 parts:

The piston

The gas spring

A plastic spacer/washer that fits between the gas spring and the trigger unit

The T-06 trigger unit.

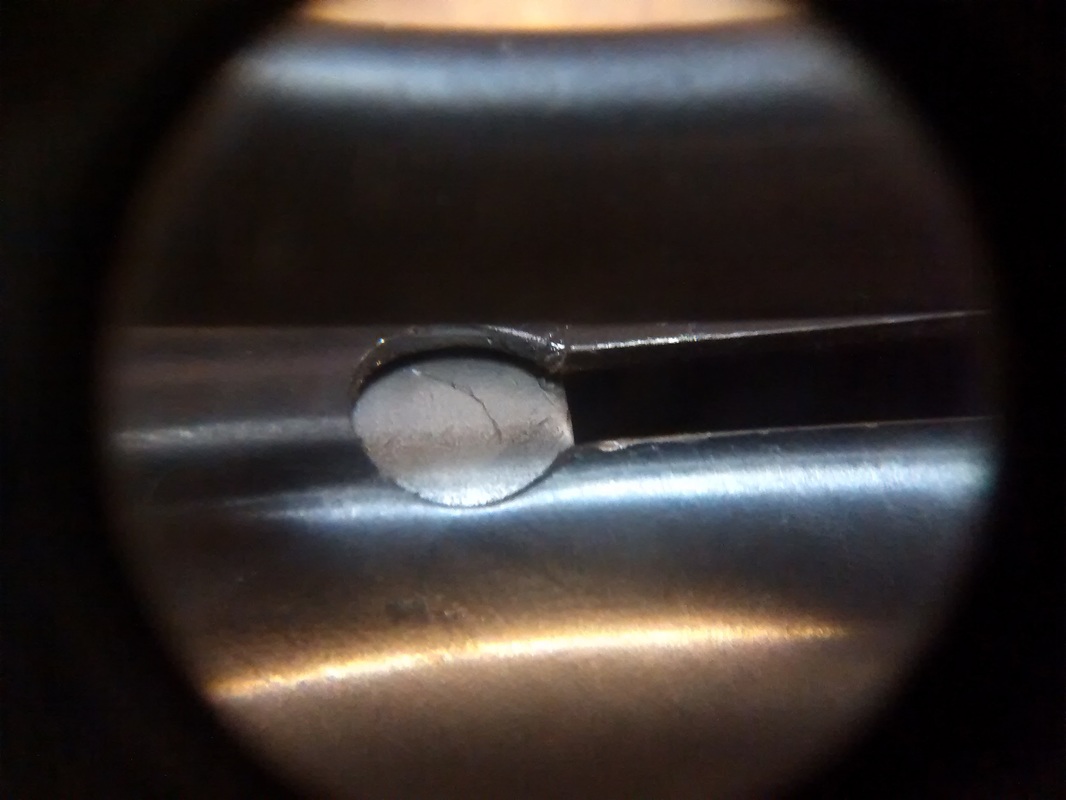

In opposition to the traditional T-06 trigger, the N-Tec T-06 trigger is an "interference" trigger. That is, it grips the base of the piston's skirt and does not allow the piston itself to go forward. There is no claw, no plates, no balls. Just a ramp that, when the sear releases, allows the piston to slip forward, much like an archer's release

While some have complained about the N-Tec T-06 trigger, I found my units to be surprisingly smooth and consistent in their release. A true pleasure to shoot with, like the other T-06 triggers in the Diana lineup.

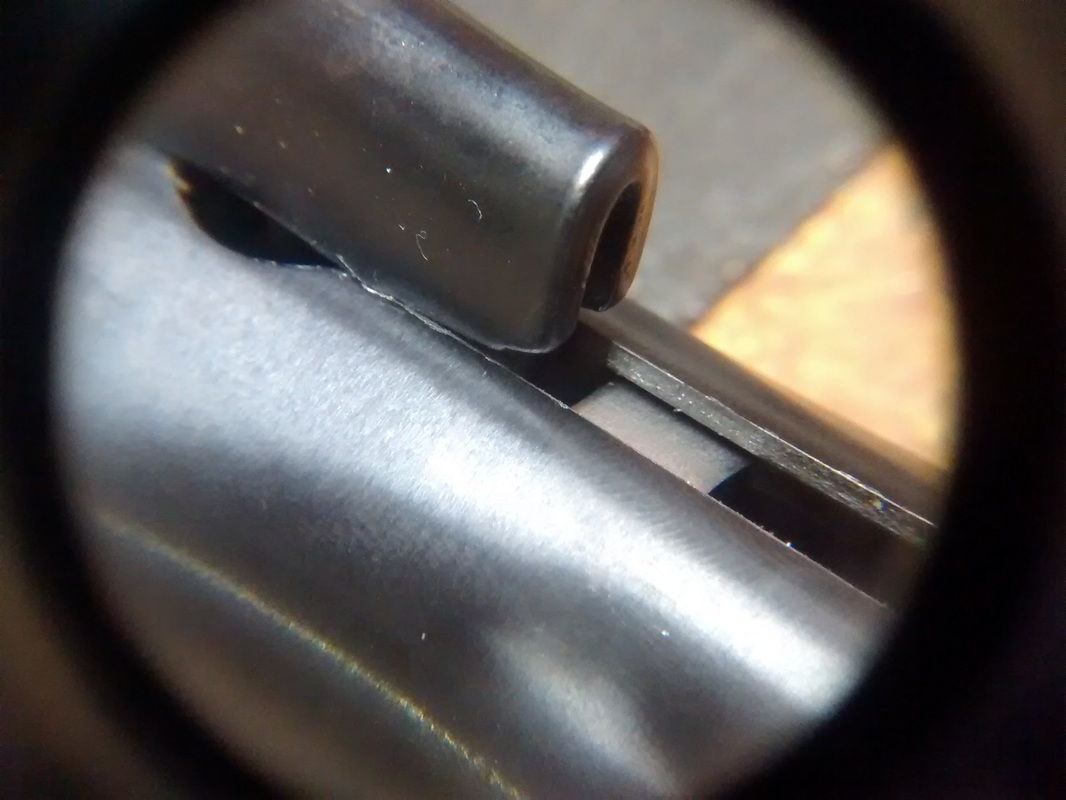

The piston lacks the stem and has a little longer body:

An interesting characteristic of all T-06 triggers is that they can be adjusted out of the gun. By pushing forward the lever that is visible in this picture, the trigger is armed and the release can then be set to the user's wants.

Do note that the trigger housing is also longer, so that means relieving the stock inletting, but we'll see that later.

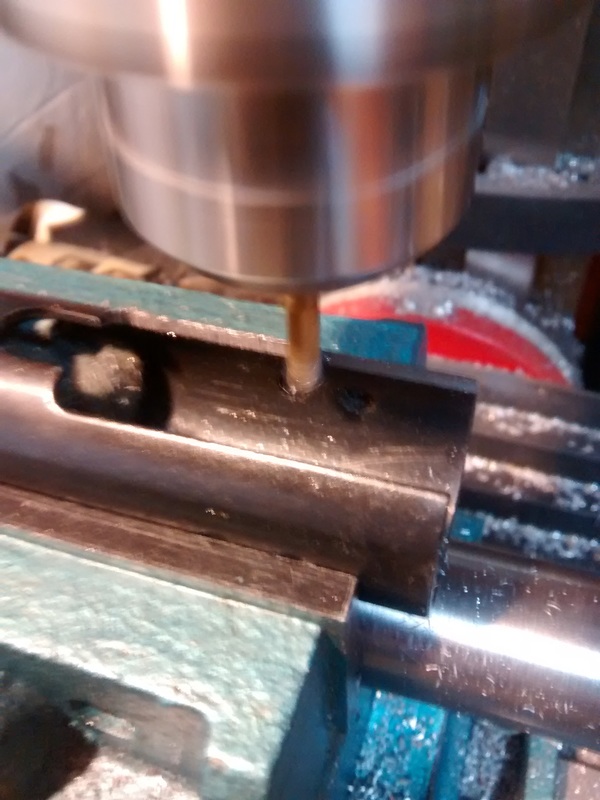

After the rough milling some scraping got rid of all those whiskers and shavings.

Don't forget to lube lightly the gas spring stem in any N-Tec system.

While 16 ft-lbs may not seem much, do consider that it's twice the rifle's weight with the Vortex Crossbow scope installed..

Shot cycle is not harsh. Sudden, yes. Quick and Forceful. Very convincing. It also suprised me that the recoil is straight in line. No jump. Of course the rifle's architecture has something to do with this, and it is one of the reasons I am not in love with the current N-Tec offerings.

Apart from the 33.33% increase in power, the gun is easy to cock, even with the carbine's short barrel.

I cannot judgea accuracy right now. Some fantastic groups (3/8"@ 35 yards) and some not so good (1" at 35 yards). I think we need to let the old girl settle down to her new powerplant.

The N-Tec architecture is interesting even without the Nitrogen piston. Future work will involve doing the conversion in a D48. I do not expect the same level of energy output increase in the short transfer port models as opposed to the long transfer port models, but it will be interesting to see what happens there. Of course, the aim in the long run is to have a short-stroked, gas springed Diana 54, shall we call it the 540? LOL!

The new interference trigger opens a whole new avenue of interesting possibilities, so we will be doing some work there in the future.

The gas springs have come a long way from the old RX-2 / HW-90 technology.

New gas spring guns are smooth to cock and efficient in the use of energy, unlike the older specimens.

Hopefully, one day, Diana will offer a true Gas Ram, where the power output can be regulated by regulating the initial pressure in the gas spring.

Whatever happens, I am glad to have been corrected about my bad impressions of the gas springs.

Keep well and shoot straight!

Héctor Medina

RSS Feed

RSS Feed