Among the things we discussed was the idea of expanding DIANA's offerings to the shooters by using OPP's (Other People's Products).

While that did not make me very happy, I understood the need of the company to SURVIVE to then THRIVE (and we will go into that in another blog entry). It was a need mandated by the conditions under which GSG acquired DIANA, and the modern, virtually borderless world we live in.

As time passed and the specifics became known, there was one particular element that intrigued me no end; a small PCP carbine that is marketed around the world under different brands: Artemis, SPA, and others I surely do not know and cannot even pronounce.

DIANA decided to market this small carbine under the name "Stormrider", so as soon as Air Venturi / Pyramyd Air had them in stock I ordered one.

Around that time, Tobias and I met again at the Pyramyd Air Cup 2017 and even more interesting conversations ensued. Nothing firm, but a willingness to work together and the idea of a visit to Ense, to get to know the people there and have some technical conversations. The date was set and a couple of weeks before the trip, my first Stormrider arrived at the workshop and I proceeded to a full analysis and disassembly.

Before we progress any further. my legal counsel again has the floor and he says:

The modifications and operations performed in these tests, and described in this article, were safe for the gun in question. No warranty is given nor implied that these modifications will work or are even safe in other guns of the same style, marketed under different brands.

Working with High Pressure Air has its own risks. If the reader is not fully cognizant and familiar with these, he/she should have the work performed by an established and reputable professional.

OK, so we're done with that! LOL!

Another thing that should be stated categorically is that DIANA's intention, from the "Head Honcho" down to the rest of the Team is that guns marketed under the DIANA brand WILL be as good as can be had OoTB within their class and market niche.

So, let us start then, and I would like to state unequivocally what the Stormrider is NOT:

If you want a gun that gives you 50 shots at 22 ft-lbs, even when shot in quick succession using a magazine, get a P-1000. They are great guns, difficult to work in and difficult to "tame", but they are great guns, powerful and accurate and they have a ton of shots with their 4,500 PSI /300 BAR's tanks.

While some have said that it is a "little" carbine, I do not fully agree, the reality is that is has a full size LOP:

And the distance between the rear of the pistol grip and the trigger, are not for a 10 year old's hands.

If you have considered the Stormrider as good youth/petite's carbine, just be aware that you may have to trim the stock to fit the shorter LOP's needed by those smaller shooters. And that they will have to learn their trigger hand hold and trigger squeeze/release accordingly. It is, though, a svelte lady, and definitely not a rifle, so let's think of it as a carbine.

We will not delve into the OoTB behaviour, that has been researched and reviewed enough in the excellent Hard Air Magazine , in Pyramyd's "Insyder" as well as their sponsored blog, and in several other Video reviews, just go to YouTube.

What surprises me is that in ALL reviews, the main "selling" point of the carbine is its price.

Well, surprise! I am going to go against almost everyone else and tell you that the great attraction of this little carbine is its POTENTIAL.

Yes, to make an analogy that will surely date me as an "old geezer", LOL!, I will say that it is like buying a simple Chevy Malibu (or Dart. or Mustang) and turning it into a small but extremely interesting race car.

Let's start with

The Trigger

First of all any half baked gunsmith can stone/polish the sear. Yes it is a lengthy process if you want to do it right. But you can do it without any sophisticated tools. You can use wet-or-dry paper laid on a piece of thick plate glass and progressively use grits: 380, 400, 600, 800, 1,000, and 1,200 with water. If you want to get it really well done, then a sliver of black hard Arkansas whetstone (which you should have if you are a hunter because nothing gives a better edge to skinning knives than black hard Arkansas whetstones) can give the sear the ultimate polish.

Avoid using a Dremel because you do NOT want to change the angle or the flatness of the sear.

You should end up with something that looks like the above piece.

Next comes the trigger blade:

A home tinkerer can simply adjust this screw that regulates the engagement of the sear into the hammer and can turn the trigger from a lengthy and/or gritty experience to the proverbial "breaking glass rod" of a trigger that is conducive to good shooting.

A professional gunsmith will reverse the direction of insertion, use a stubby allen wrench (1.5 mm's), change the screw and use either a rounded/polished face screw, or a cone point.

If the polishing of the sear was well done, the cone point offers a degree of repeatability that the rounded face screw does not. But only if the polishing phase has been done properly.

If properly done, the trigger can be as light as a fraction of a lb.

AGAIN: ALWAYS MAKE SURE YOUR GUN IS SAFE! Submit the gun to the bump test: dropping it butt down from 12" height and it should NOT fire. If it does, readjust and repeat.

The trigger will be a single stage trigger, there is no way around that, though we are working with DIANA on a new design that will be a true double stage trigger.

Of course, do not forget to Loc-Tite your setting!

For a modicum of effort and very little cost you will have a trigger that breaks cleanly and consistently, and depending on how well you did your job, it can also be very light and still safe.

A note here: NEVER use lubricants between sear parts. It will provide an inconsistent release that will be thermally sensitive and what is safe in temperate/cold weather may become completely unsafe in hot weather. Let the hardness of the metal injection molded parts and your polishing do the friction reduction.

Now. let's go the next area:

The powerplant in 0.177" cal.

In general, I would say that the 0.177" cal. is a target/plinking/expert hunting caliber. You need to be a good shot to take any major prey with the smallest normally available caliber. Head shots, long stalks/short ranges, and good field craft are essential to being a successful hunter with a 0.177" cal. rifle It IS doable. Lots of our cousins across the pond do it day in/day out. But it does need a well practiced, ethically minded, and precision/accuracy oriented hunter.

Yes, the gun can yield around 20 ft-lbs in 0.177" cal. Yes it can be done, and if there is enough interest (hint: if you want it, ask for it in the comments section) we'll go there, but the OEM architecture of the gun has its greatest . . . potential! ;-) at around 12 ft-lbs.

Another aspect is that there is a ton of literature, data, serious experiments, and documentation at this power level. I would say that thanks to the FT shooters, no pellets are better understood than the JSB's Exacts in their Express (7.89 grs) and Mid Weight (8.44grs.) versions.

Experience has shown time and again that they yield VERY LITTLE in terms of BC and the gain in MV is more than enough to achieve great results with these pellets, even at longish (55 yards) distances.

Of course, it also helps that Predator's PolyMag's in 8 grs. are extremely accurate out to 45-55 yards, usually shoot well in those barrels where the JSB's shoot well, and give the GOOD hunter an extra edge of surety.

So, having explained the reasons to choose this power level, let's think out loud what is the main area of opportunity for improvement.

In my honest opinion, the single greatest area of opportunity is the shot count and consistency.

There seems to be a common denominator between reviewers to resign themselves to work with the 12-20 shot count that a relatively large and steep power curve gives, this is as much an effect of the manufacturing (and therefore a big factor in the low cost of these guns) as it is an effect of the "GAMarketing" practices of trying to sell a gun on the sheer MV or ME.

Using the SAME spring and hammer for ALL calibers has to be an extremely rough compromise. And yet that is what is done. I repeat that it is one of the factors that allows this gun to sell for under $200 retail, but technically speaking it is a HUGE compromise.

Now, to be quite frank, not everyone has the time, knowledge, nor energy (you need to refill the gun quite a lot of times if you want) to tune it the hard way (balancing the hammer weight, the stroke, the spring and the valve face). Yes it can be done, but it is not an hour's job.

So, my conclusion was that the best way to serve the shooters would be to get a good regulator for these guns.

There are already some regulators in the market for the "Generic" form of the DIANA Stormrider, but some of them are expensive (€ 89,00), some of them require the user to make some modifications to the gun, and some are not easy to de-install, should the case arrive where the user decided he was going to go the hard way.

After some research, and based on previous experiences with HPA equipment, I decided to work with ALTAROS Air Solutions to develop not one, but TWO regulators for these carbines.

Why TWO? One of them needed to be "absolute" (non-vented) regulator, it had to be user installable, without ANY modifications to the gun (as that is completely illegal in some countries), and it had to be easily de-installable.

The other was a more specialized unit that was to be installed by a licensed/certified gunsmith, and it was to be vented.

Vented regulators are more thermally stable, but they are more vulnerable in extremely dusty environments and need to be installed by a competent gunsmith because not only do they require the removal of all the internals of the gun, they also require extreme care in keeping the vent operational when assembling the gun back.

By the time DIANA's invitation to Ense came, my carbine was on its way to the Czech Republic and I already knew exactly what I wanted.

Here I have to commend the diligence, patience, and knowledge of the Altaros people. They listened, and we had some strong and energetic discussions, but the technical know-how and the needs of the shooters prevailed and the end product is more than satisfactory. Working with them was an honor and a privilege.

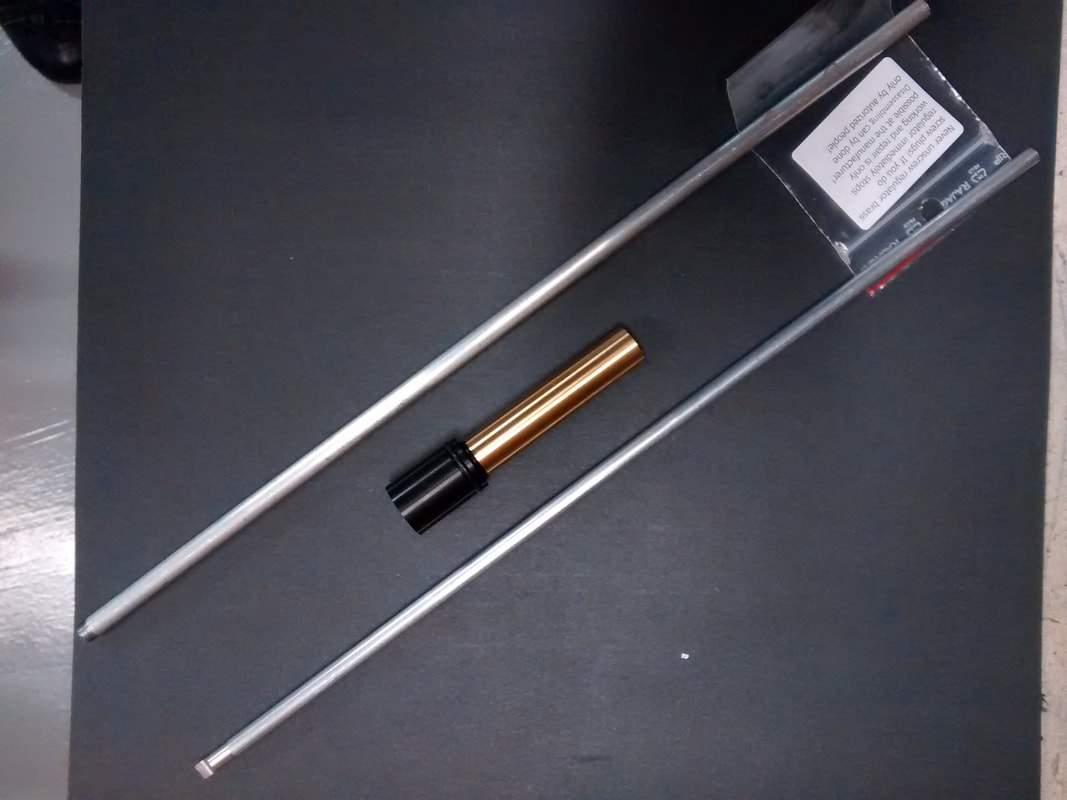

This is how the regulator looks like when delivered:

You will need to start from an empty air tube, so either degas it, or shoot it till it is empty. Once the air tube is empty, you can start the installation:

Once those screws are removed, you can take the action out of the stock.

You simply remove the end cap of the air tube (CAUTION: MAKE SURE THE AIR TUBE IS EMPTY!!!!):

We've had reports of earlier models of this gun that do NOT have the manometer sleeve and the manometer is screwed directly into the air tube/block.

IT IS NOT SAFE IN THESE RIFLES TO USE THESE REGULATORS!

As long as it is a DIANA airgun, it WILL have the manometer block and the manometer sleeve. We tested this arrangement to 300 BAR"s and it proved safe, but it is an arrangement that we cannot guarantee as safe in any gun that does not have these parts. It is up to the shooter to ensure that HIS/HER gun is safe for this conversion.

For these tests I used a Hill Hand Pump because I wanted to make sure that users did not NEED a compressor, or an air tank to benefit form this mod:

Give the pump 20 QUICK strokes and ensure that the ORings have been "set".

Then you can start the REAL pumping.

Just in case someone is not aware of this, the proper technique to use a hand pump at high pressures is to "dwell" a littte at the bottom of the stroke.

I drop my full weight (all of my 168 lbs) on the pump handle and count slowly "one", and then raise the handle, then repeat.

The Storm Rider takes 100 more pump strokes (apart from the 20 used to set the ORings) to go from 0 to 220 BAR's.

Once everything is working, it takes just 45 pump strokes to go from 100 to 220 BAR's

By now, I am sure someone is calling me crazy. Why would I pump a gun up to 220 Bar's when it is clearly marked 20 MPa (200 Bar's) max?

Well, on one hand because it is perfectly logical, productive and safe now.

One of the aspects of that huge technical compromise that comes from using the same parts for all caliber guns is that you cannot risk a valve lock. Pumping/filling to more than 200 BAR's is just tempting fate. A valve locked PCP is a grenade just waiting for the next dumb person to pull the pin. That would not be good and so it is to be avoided, but now that we have a regulator, we can pump it JUST above and be perfectly safe.

The 220 BAR's fill point is within the capabilities of the excellent Altaros regulator and it gives a good boost to the shot count and performance of the gun that would be otherwise impossible.

The overall process of opening the air tube, inserting the regulator and refilling the gun takes all of 47 minutes, and that is taking photos along the way, I am sure that it is "quick work" for someone not in the habit of making blog posts, LOL!

But, what have we gained for our investment and our time?

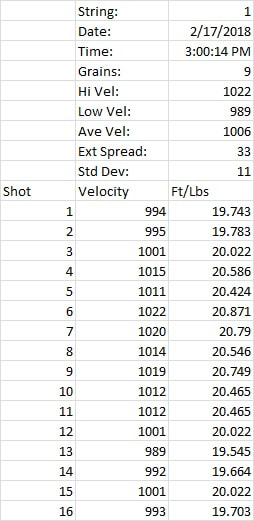

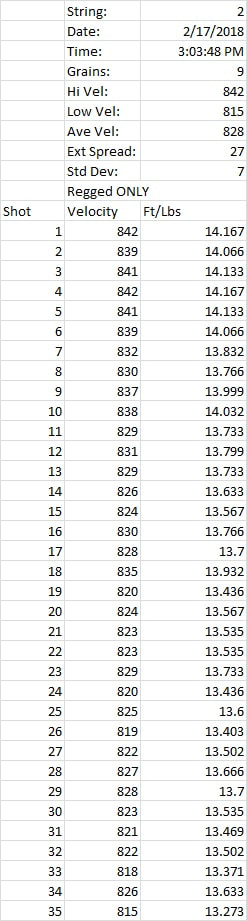

The short answer is that we have gone from "12 - 20 usable shots" (16 in our case) :

So we're trying to compare similar situations. The eagle eyed among you will note that in the "as issued" case the gun was a "20 ft-lbs gun" so, yes the gun was delivering more power, but what is so important about power when you have such a wide variance of MV's, the pellets are not flying at their maximum stability speed and above all, when your machine is being totally inefficient????

Airgunners pride themselves in the ability of their airguns to hit small targets at the needed distances with sufficient efficiency, consistency, precision and accuracy for a good hit. Whether that means a clean kill or a downed target, or a perforated bottom of small can is irrelevant.

But, like they say on TV: "WAIT there is more!" ROFL!

I said that the machine was inefficient. And if you REALLY want to explore the limits of the efficiency of such a small machine, you will have to work with it the hard and long way, but there is a shortcut:

You can "choke" the machine at the point where it is starting to be inefficient and render it more efficient.

How?

Simple! Tailor the Transfer Port to the needs of the pellet.

¿THE PELLET? What is this guy talking about? We're talking about the rifle! ¿no?

;-)

Yes, but at the very instant of releasing the air blast into the barrel, the pellet is the last "valve" in the system, and therefore a combination of the pellet's weight, hardness and head & skirt diameters will determine what is the "release pressure", thereby effecting an impact on the overall efficiency of the system.

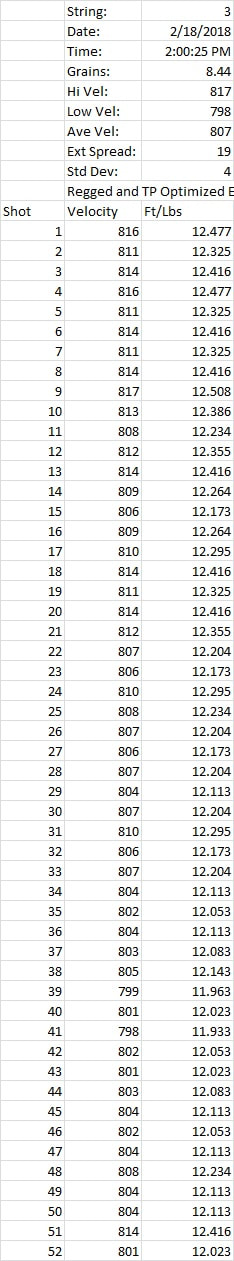

Because PCP's tend to be more efficient with the heavier pellets. I chose to optimize the TP to the 8.44 grs. JSB. and so, after some fiddling with successive numbered drills. I found what I wanted: the smallest TP that will deliver the desired energy, in this case something reasonably close to 12 ft-lbs, and this is the result:

Good enough for a medium FT match, or a good 3X10 run, or a good night at the stables getting rats. Pigeons in barns and stables need a different approach, and we'll get to that later, when we explore the 0.25" cal.

Do note that we do use "full ballistics data", we do NOT exclude those shots that are questionable, like shots #39 and # 41

Because the "fiddling with the TP" does NOT require "deflating" the gun, I think it is within the realm of most shooters to do.

Are there other ways to improve on the efficiency? Yes! the main one would be to play with the hammer weight and the spring force. But that takes time and knowledge.

Are there ways to have a gun that is regulated and still puts out 17-18 ft-lbs? Yes! We started with a "low side" pressure of 100 BAR's. Adjusting the regulator up will also move the speed up. Why would I stop at 18 ft-lbs? because pellets are not stable much above 875 fps and if you do the maths, that is the speed at which the 10.5 grs / 0.177"cal. pellets reach that energy.

Again, if there is interest, we can come back to this point and explore other "regions of operation".

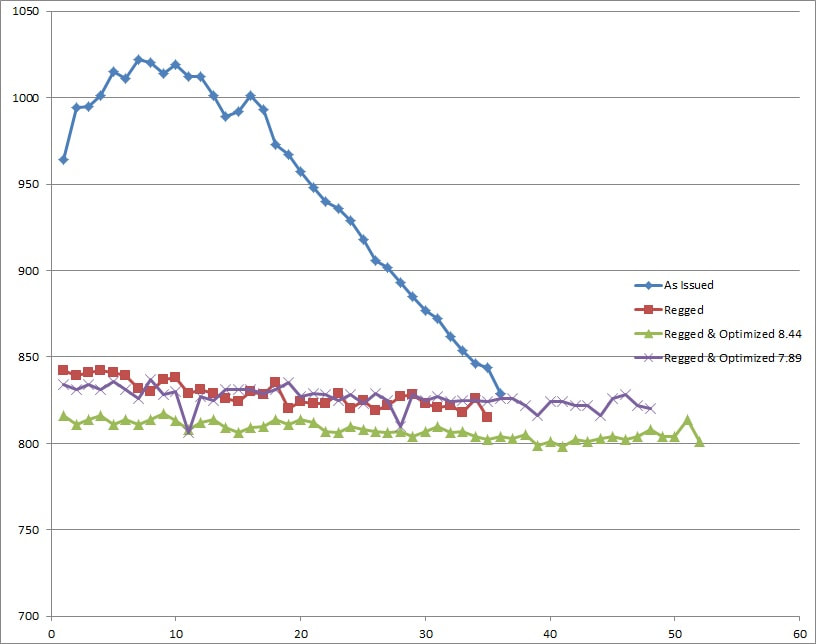

For those that are graphically oriented, here is a chart showing the comparative charts:

And just to finish off this section, let me tell you what was the TOTAL DELIVERED ENERGY for each case:

As issued, the gun delivered over the 16 shots 323 ft-lbs.

Regged, the total energy delivered was 480 ft-lbs

Regged and Optimized for 8.44, the total energy delivered was 636 ft-lbs

So in return for your good 45 pump strokes, you get much more when using a regulator and an optimized TP.

Many times we have discussed that MV is not everything, sure it needs to be delivered inside an accurate barrel, but in this case I would say that other reviewers have established that these guns are accurate as they come, regulating them can only help. And that while consistency and stability is not a SUFFICIENT condition for precision and accuracy, it is indeed a NECESSARY one.

If there is interest, we will explore other aspects in different calibers.

Hope you enjoyed the read, keep well and shoot straight!

HM

RSS Feed

RSS Feed