Opening comments

Courtesy of our friends at Aer Lingus, that delayed my departure from Washington (Dulles) and made me loose my connection to Birmingham (and the World's FT Matches), I've had to sit in the airport then attempt a boarding, only to be denied boarding on account of my "firearm".

You see, there are planes in the Aer Lingus fleet where you can access the hold, so in those planes, "firearms" cannot travel.

It doesn't matter that it is a single shot, pellet rifle, disassembled, and unloaded (obviously, who in their right mind would carry a cocked springer without a stock and with an exposed trigger?!)

The computer terminal says it cannot travel and the employees cannot exercise neither judgement, nor criterion, they are not allowed to think.

So, let's talk springs!

This entry will be completely different from all the others in the sense that it will try to PROPOSE improvements to the current state of the art, more than analyzing what is the current state of the art.

I believe that more informed consumers will always drive manufacturers to a better product and in the end, we all win.

Suggestions for improvement open to all Manufacturers

Let's start with some clarification of concepts:

A steel spring is a series of coils. You might say that is obvious, but the truth is that what is not obvious is that each coil behaves more or less independently and in those things where they act together are those factors that affect the interlinkage of the coils and have the most effect in the long term life of the spring.

Like a train, if a spring is not properly "loaded" it will get de-railed.

Experienced railroaders know that if you put the light cars in the middle, and the heavy ones in front and in back the train "stretches" and cannot follow the tracks (like "Tootle").

So, trains are "loaded" in certain order and then locomotives are inserted at strategic points in very long trains (in excess of 100 cars).

It is not uncommon in the US to see long haul cargo trains with up to 16 locomotives distributed along the beginning, the end, and both(1st and 2nd) thirds of over 170 cars.

An airgun mainspring is not that different.

Its relation of Overall length (OAL) to Outside Diameter (OD) renders them very "slender", and so, prone to "derailment" (kinking), stretching and knocking (twang), and even bumping (buzzing or vibrating).

So, how could we build a better spring?

SOME improvements could come from the science of materials.

In the automotive industry the effect of different alloys, heat treatment, methods of heat treatment, surface finishes and even coatings has been studied in depth.

Those of you that are old enough will remember that valve springs would hardly last 10-15,000 miles without loosing some of its "oomph", this required constant "tuning" of the engine. Usually, every 3-5,000 miles, and then change of springs.

Modern valve springs will last well over 100,000 miles. Even "racing" springs can now last at least a season (not an interesting aspect in high budget racing, like F1, but interesting in other forms).

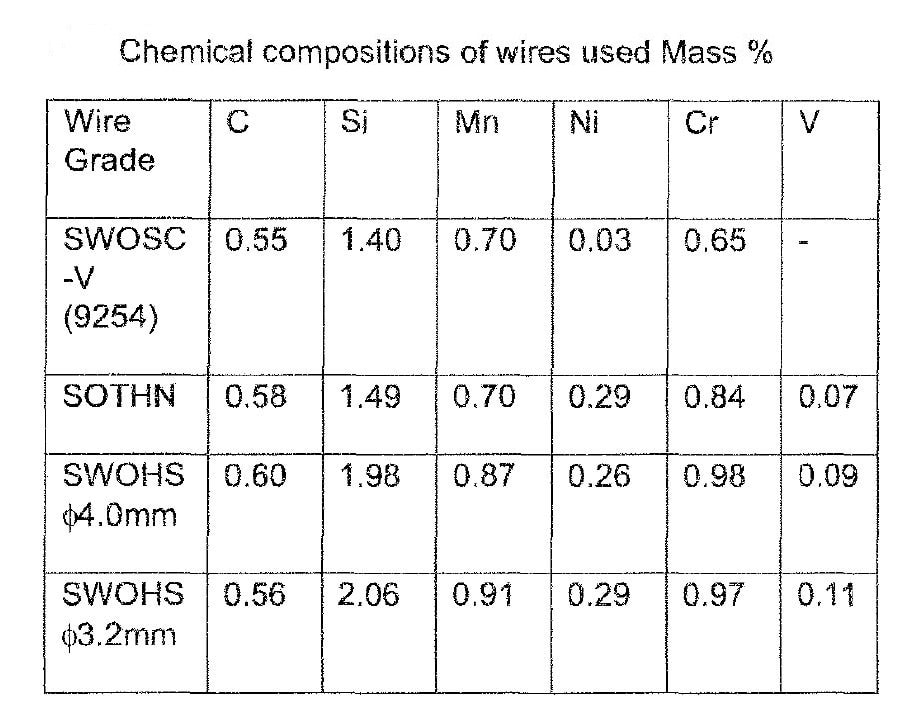

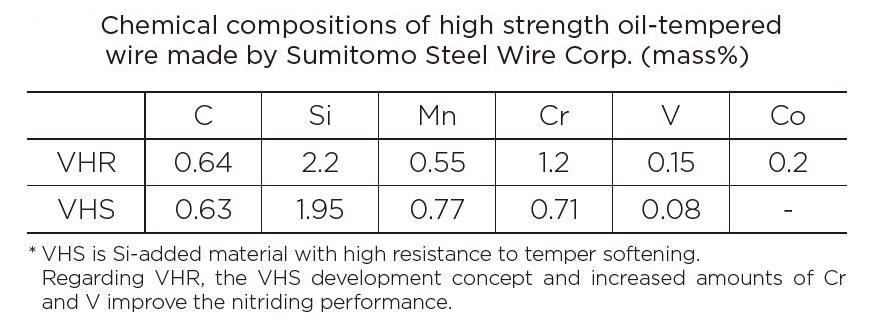

Up until 50 years ago, High Carbon steel spring as produced by the US or Swedish firms was the top material. A concerted effort on the part of Japanese car makers brought a full range of innovations: Chromium was added, then Silicon, then heat treatment prior to winding, then Vanadium was added to the wire (not as an alloy), lastly Cobalt; and very serious studies have been conducted about what is what TRULY defines the fatigue and temperature resistance of springs, to this date, most (by volume) truly high quality spring steel is produced in Japan.

Of course, given the vertical integration of the Japanese economy where the same "group" is composed of companies ranging from mining conglomerates to car making (Mitsubishi is a good example), or where the close alliances between industry, banking and commerce create de-facto groups (Sumitomo), it is not complicated to setup an institute to research these things.

Luckily, they are generally open with those things that are at least 5-7 years old, and we can take a peek into what it is the current, published, state of the art.

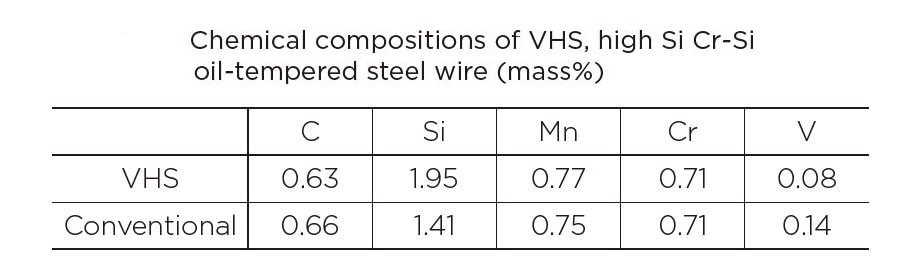

So, let's compare how successive generations of valve spring steel compare to "piano wire" or "conventional steel":

Do note that this table is courtesy of Sumitomo Electric, so the names of the steel are "commercial":

And this is where Sumitomo is currently, adding Cobalt (Co):

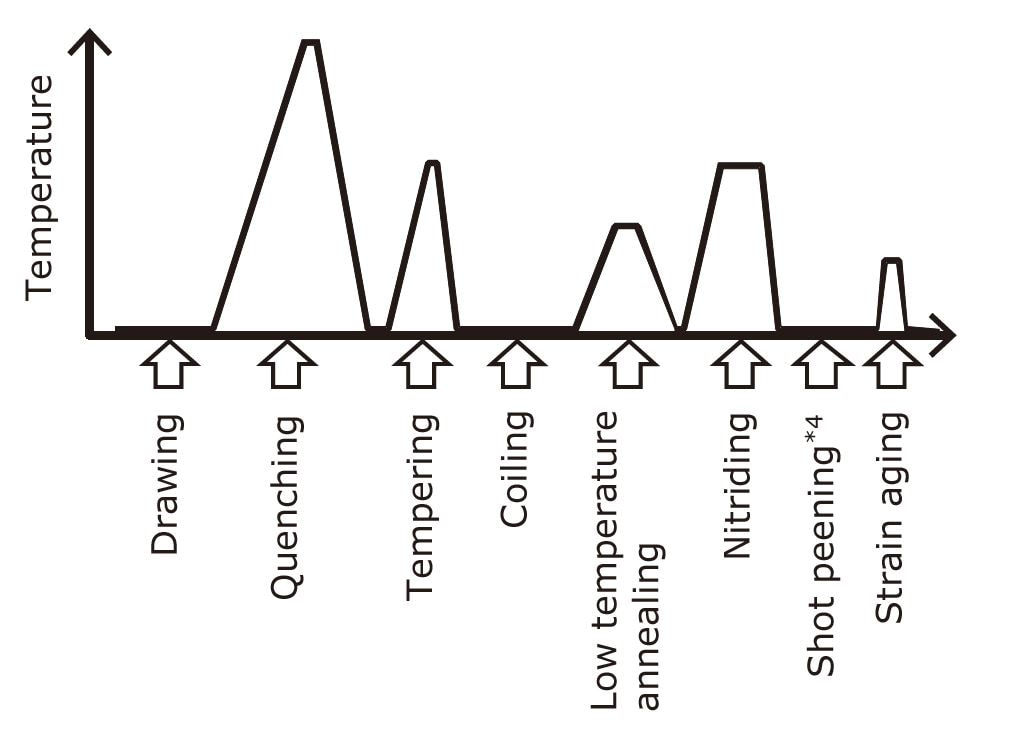

Pulling the wire through dies creates some work hardening as it is "drawn", but then this hardening needs to be quenched in molten baths (either lead or salt composites) at a higher temperature than that of the drawing.

Steel at this point would have little hardness and little tenacity/toughness, so it needs tempering.

After tempering, then the spring is wound or coiled.

But this tempering process, even if it is conducted at relatively low temperature, requires some annealing in order to make the spring less fragile.

Then the surface is treated with Nitrides in order to create a "case" that exhibits superior resistance to the starting of cracks and fissures which are the weak spots where the spring breaks, while still retaining a "core" with tenacity and toughness.

But while niitriding creates the chemical aspects conducive to surface hardness, it also stresses the surface itself. So these stresses need to be relieved and the most economical way to relieve them is to "shot-peen" the spring (some manufacturers use small bits of wire to shot peen, not actual spherical shot).

Finally, the spring is subject to a certain portion of maximum allowable stress and "aged" by the strain this stress creates (what we would call "setting", though we set the springs by compressing the FIRST time to fully solid condition).

There are techniques to strain-age airgun springs, but not all airguns are suitable for them.

After all these processes, the resultant spring is capable of MILLIONS of operations within the design parameters, and here we note that NO AUTOMOTIVE spring reaches the compression ratio of airgun mainsprings.

Would an airgun spring manufacturer be able to buy these super-special steels?

Maybe, I really do not know. My calls for information went somewhat unheeded as to what material each manufacturer uses, so I cannot tell you who uses what and what processes are applied to our airgun springs.

I am sure that they all do the best they can within the constraints of the costs they can face. And this is an important consideration.

An OEM spring costs between $0.50 and $4, an aftermarket spring costs about $10, some VERY special aftermarket springs can cost up to $25, most of them are sold for between 2 and 3 times the cost, not all of them are truly worth the price the consumer pays but, when you consider that a gas spring, in industrial assembly quantities can cost between $5 and $25, it is clear that extremely advanced steel springs will never make it to the OEM piston gun.

Now let's look at a little geometry

The first coil supports and pushes the second that in turn does the same with the third, etc. BUT if we think about this closely, we will understand that the first coil is pushing ALL the next coils, and that in the other extreme, the last coil is pushing the piston itself.

Yes it receives the support and push from all the previous coils, but this difference make the "distribution of labor" different for each coil depending on WHERE that coil is in the spring.

This concept also clarifies that the WEIGHT each coil is pushing, depends on the position in the spring.

And lastly, this concept also helps us understand that once the whole length of the compression chamber has been run by the piston, and the piston itself suffers the pushback from the pellet's inertia/resistance and high pressure thereby developed, a whole mayhem of disorderly conduct ensues. Some coils go back while others go forward, and some stay more or less stationary. These "travelling waves" of steel actually make the spring perform several compressions and decompressions for every shot cycle.

The most common way to solve that is to use a tight fitting guide.

A tight fitting guide will provide some coils with enough friction to dampen their movement.

And so, we eliminate the twang and the buzz.

We also reduce the double and triple duty cycle that some coils perform.

But, as much as we would like to reduce completely this aspect, we cannot. We cannot introduce so much friction that the extra movement of the coils is completely arrested. We would not get the speed we need to drive the pellet.

So, we need to accept that as long as we use a coiled steel spring, we will need a tight guide, or accept the twang and the buzz.

The natural question here is: Why don't manufacturers use a tight guide from the start?

Answer lies in the cost, of course.

And the REAL answer is that to make the springs, the steel needs to be coiled (remember the 4th step in the manufacturing process?).

How do we do that?

Some of you may answer that you take a mandrel, and coil the spring around the mandrel.

Well, that was true in the old days.

Fairly elaborate mandrels were turned to set the "pitch" of the spring, and the diameters had to be not only calculated, but then rectified by actually making a number of springs.

Because, depending on the force you use to restrain the wire from winding freely, the spring will always be fatter than the mandrel; more force, less difference between mandrel's outside diameter and spring's inside diameter.

Nowadays, springs are wound using mandrel-less machines that simply start bending the wire along an adjustable curve and the spring wire is "pushed" into form, not stretched.

This means that you are not limited by the length of your mandrel. You can make REALLY long springs. And you can also adjust the dimensions to a fine degree: Inside Diameter (ID), Outside Diameter (OD), Pitch (P).

Some aspects that are seldom questioned are: What is the INTERNAL geometry of the spring, and why, where and how does the spring accumulated energy?

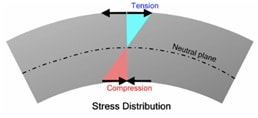

To understand that we need to look into what is the "Neutral Fiber", "Neutral plane", or "Neutral Axis"

RSS Feed

RSS Feed