Gun # 1.- An Olympic Class gun, even by modern standards

I was curious on several fronts:

- What were the changes made between the LG55 and the LGV? (after the analyses I refuse to call them improvements).

- Why, regardless of the changes, the performance of the brand at top competitive levels during those years still struggled?

AND:

- Why did Walther decided to redo COMPLETELY the LGV for the 2015 incarnation?

Once all the issues were corrected the LG55 had proven to be a delightful little gun to shoot, and capable of MUCH more than middling accuracy.

So, we procured not one but TWO LGV's from the olden days (¿Golden Days?), one from an early manufacture and another from a later date.

Both were advertised as "Defekt" in the sense that we KNEW they would need a re-seal (to say the least).

But, we went ahead and procured them.

By the time they arrived, I was somewhat busy, and so the project had to be put on hold.

With some other projects out of the way and the series of articles on Spring-Piston rifle Dynamics well on its way, it was time to get the first one done.

Since this gun is a later version, with the "UIT" stock (my friend MDriskill corrected me about the difference between the "Olympia" and the "UIT" stock) and adjustable Match trigger (even the blade is adjustable), it was decided to set this to "F Im Fünfeck" power level (that is 7.5 Joules or about 5.5 ft-lbs, which is the standard for Olympic 10 M match).

The gun is a good looking gun:

As you can see the somewhat earlier DIANA 65 has a more rounder stock, and the LGV has a more "angular" stock. this stock would later be reflected in the DIANA 66

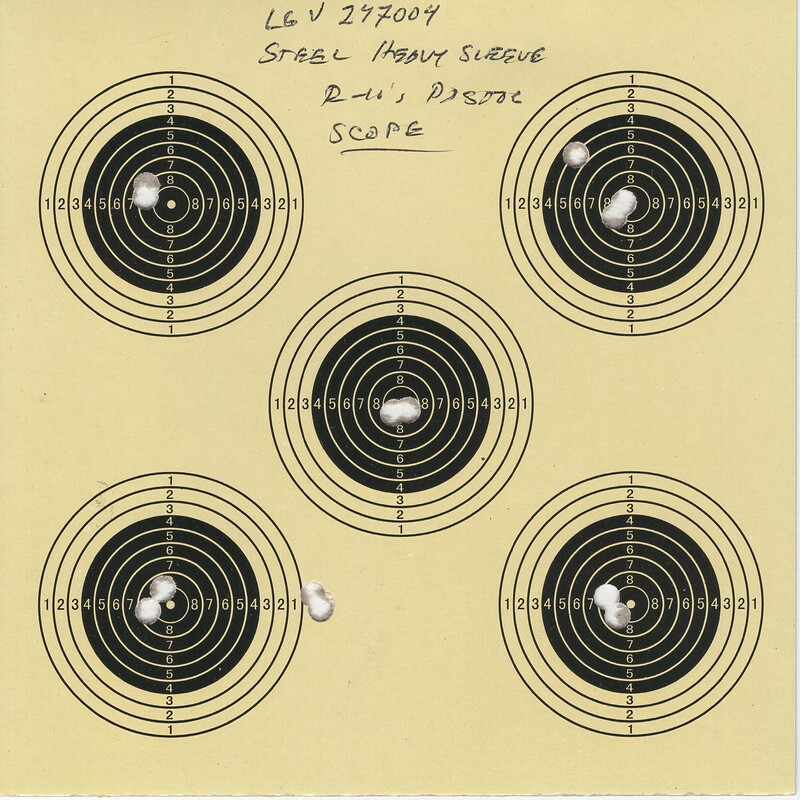

A BIG surprise was the steel sleeve in the LGV barrel, that is a HUGE chunk of steel, weighing over 770 grams (1.7 lbs).

At first I was somewhat leery of the OEM sights, as the experience with the LG55 had proven they were totally inadequate. But I decided to move forward and observe.

I will not go into detail about the disassembly process, as it is the same as the LG55, but I will say that even after the half decade that passed between the 55 and the V, the seals had not changed and still posed a serious problem to the health of the gun.

This gun in particular was shot extensively, then abandoned.

The seals were not a crumbly mass, but a goeey/sticky/slimy gunk. Perhaps someone decided that Ballistol was capable of everything, including resurrecting dead seals, and had added some hydrocarbon that dissolved some of the seal material and then as it evaporated, left the mush in the compression chamber to be cleaned by the next gunsmith (me).

Grrrrrrrrrr!

Anyway, Acetone to the rescue!

After stoppering the TP with a wooden dowel, acetone was poured and left for periods of time to soften the mess inside. And changed often.

Then a soft brass rod was polished and shaped to the inside curvature of the compression chamber to have something to dislodge the mess.

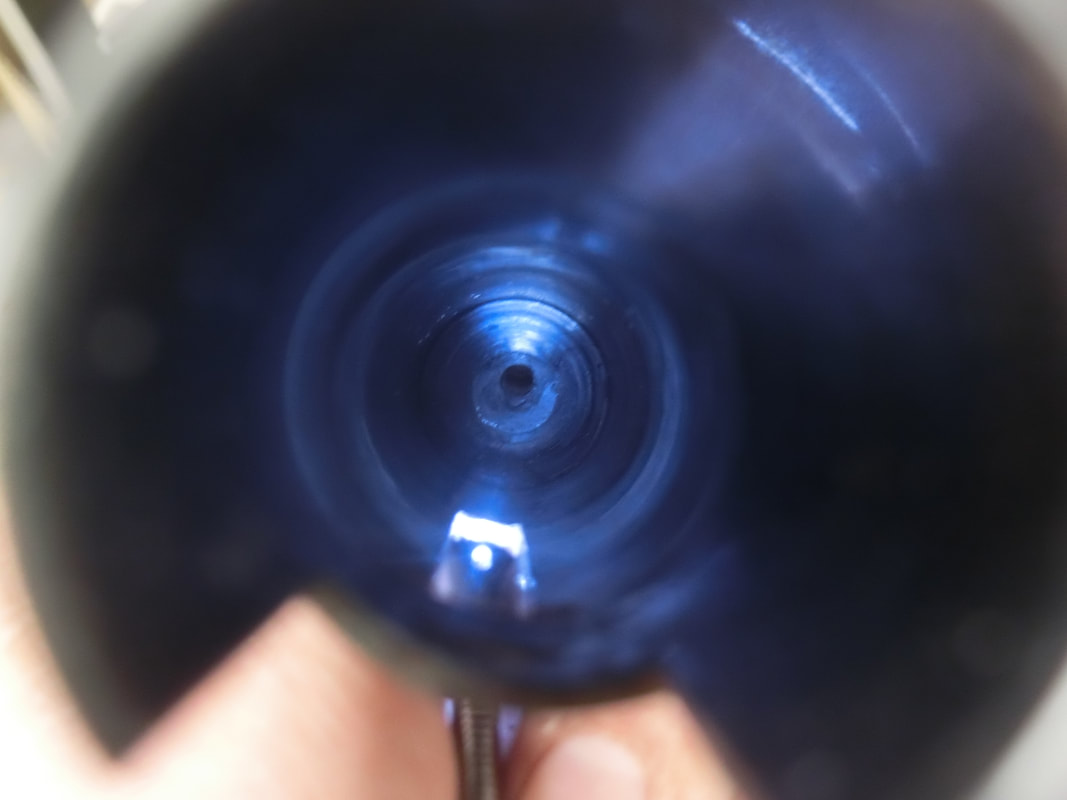

Little by little, with patience, and over two days, the whole thing came out:

Once the compression chamber was clean, we could see that, while the LG55 has a straight and short Transfer Port (TP), the LGV has a long and slanted TP. For the extremely small volume of the machine, this is really not necessary, and it detracts from the efficiency of the engine.

The piston was re-built using almost the same technique as the LG55 (allowing for the central, but long TP), and we tried the OEM spring with the intermediate "double guide".

Results were less than encouraging.

Velocities in the low 400's and extreme spreads of 18 to 58, were not precisely what we had seen with the LG55

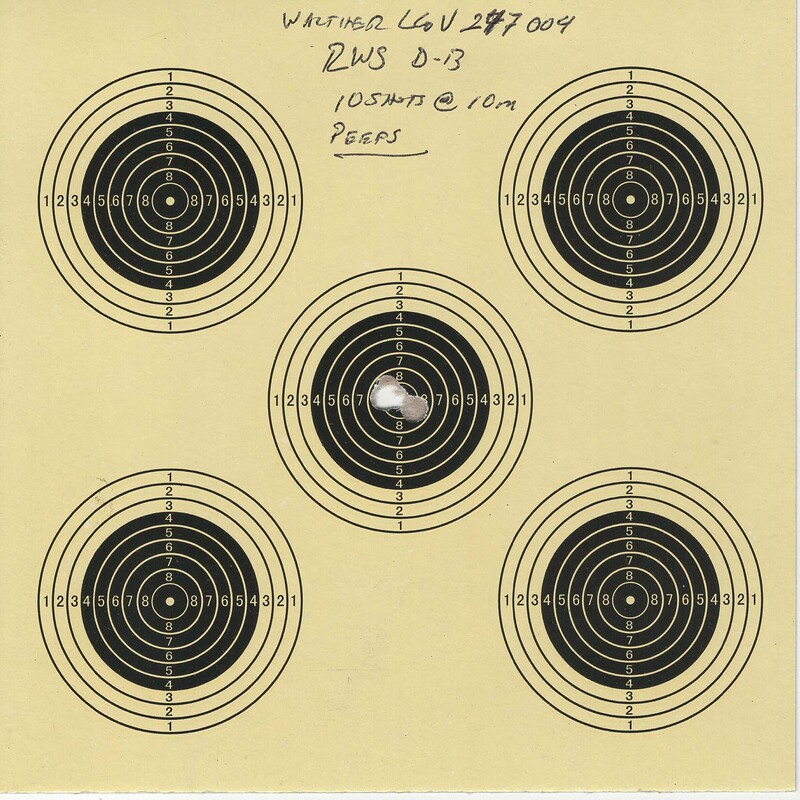

So, we inserted the one piece OEM spring (from 60 years ago), and MV's immediately came back on line: low to mid 500's were good and extreme spreads dropped to between 9 and 34.

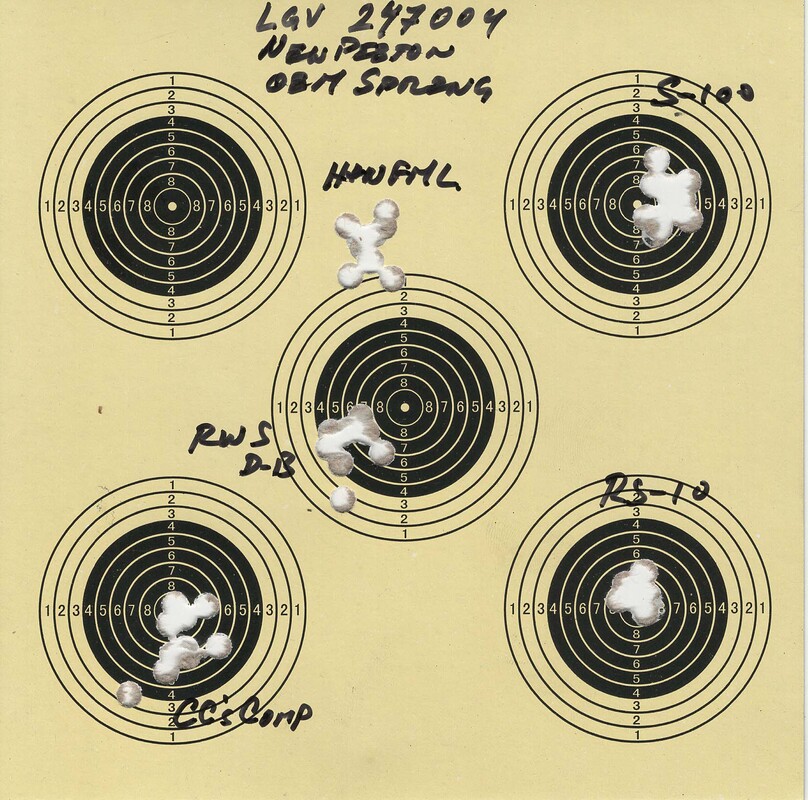

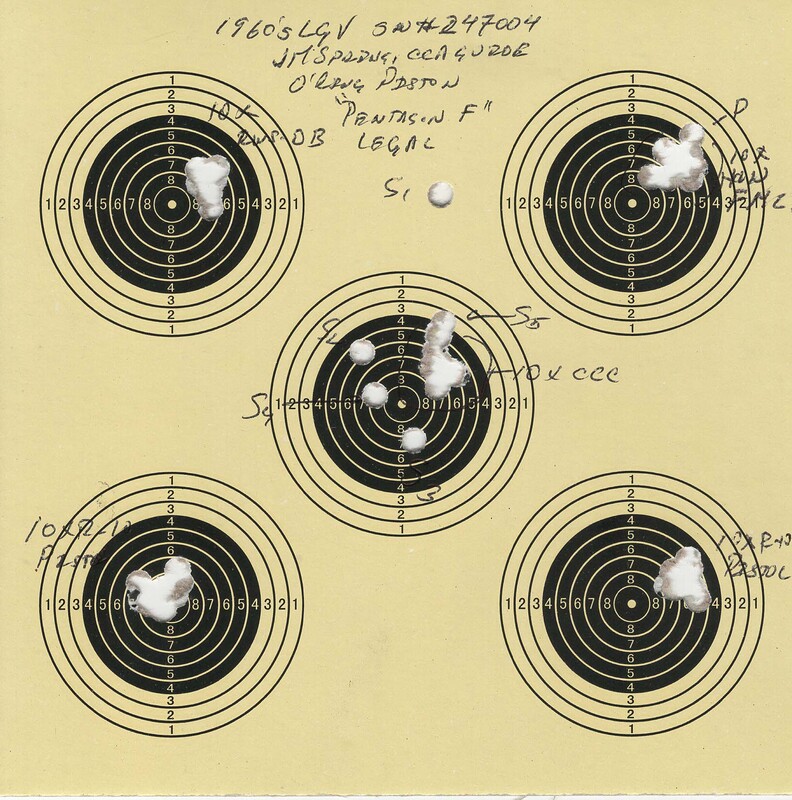

With something more in line with what we assume was a good benchmark performance back then, we shot a test target with the bare barrel:

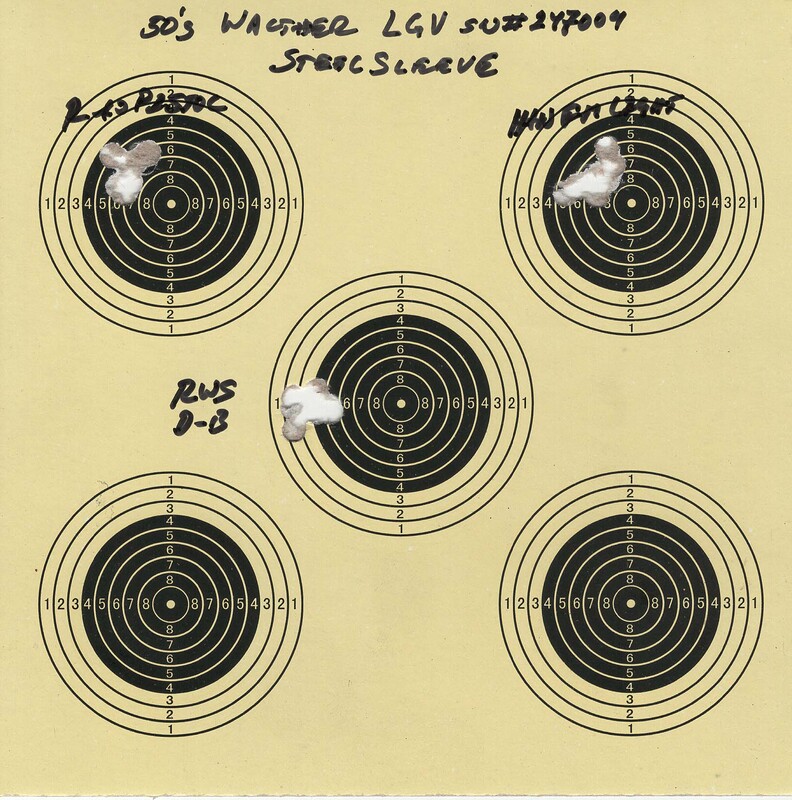

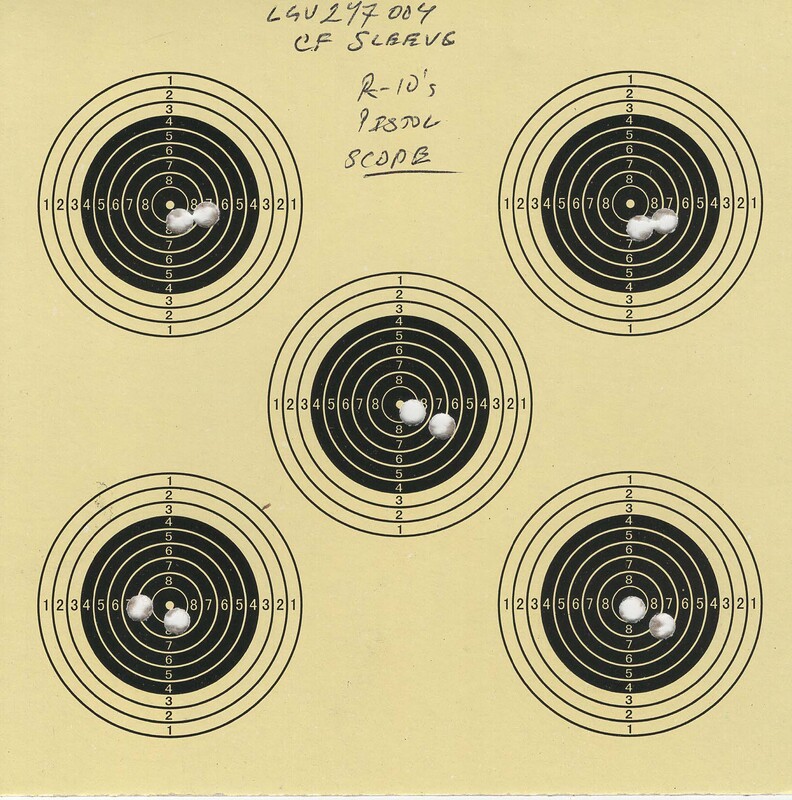

AH! I suddenly remembered that the steel "anchor" was around, so I installed it and re-sighted:

And this moment was when I thought that there was something not quite right there.

I had ordered two springs from ARH that duplicate the OEM spring, so I installed it and tested it.

Cycle was so twangy and disagreeable that I had to stop the test.

The very short "guides" that Walther incorporated into the spring locking nut were not enough.

I remembered Scott (Motorhead) experiences and decided to provide the gun with a full guide.

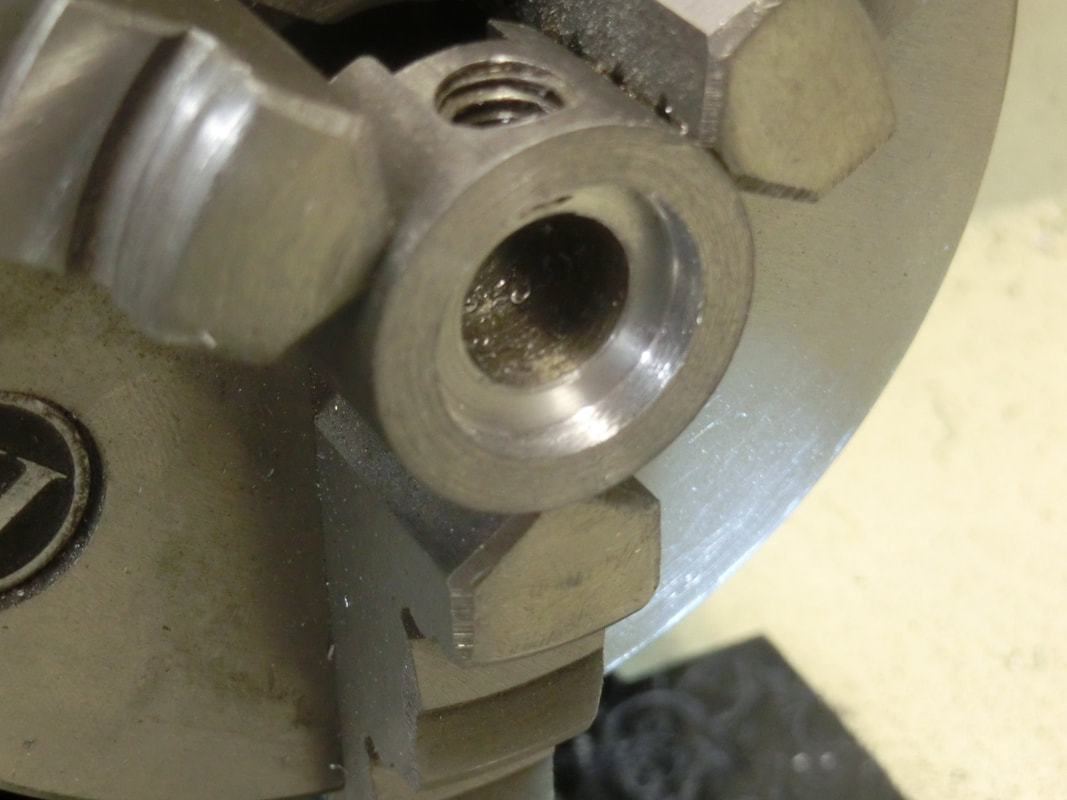

A spare OEM LG55 spring locking nut was used to make the composite guide.

First, a cavity was made in the nut:

And then turned down to dimensions:

Well one of the changes done by Wlather between the two modes was that the LGV spring locking nut (the one that can be seen in the background of the photo) became a heat treated part with the model change, and so, VERY difficult to machine.

Shot cycle became what it should be, and we tested the gun:

Yes I pulled one, SORRY! My Bad!

;-P

Now the gun is behaving as it should. In the hands of a good marksman, this gun is indeed capable of "Match grade" results.

For the second part, we will look at an early version that had been converted to an "FT" gun (German Rules with Pentagon F rifles), and we will explore the power limits of the little engines.

Keep well and shoot straight!

HM

RSS Feed

RSS Feed