The editor wishes to apologize to the readers for the delay in publishing this chapter.

The editor takes full responsibility for this delay, in no way was this the Author's fault.

So, let's get back to business:

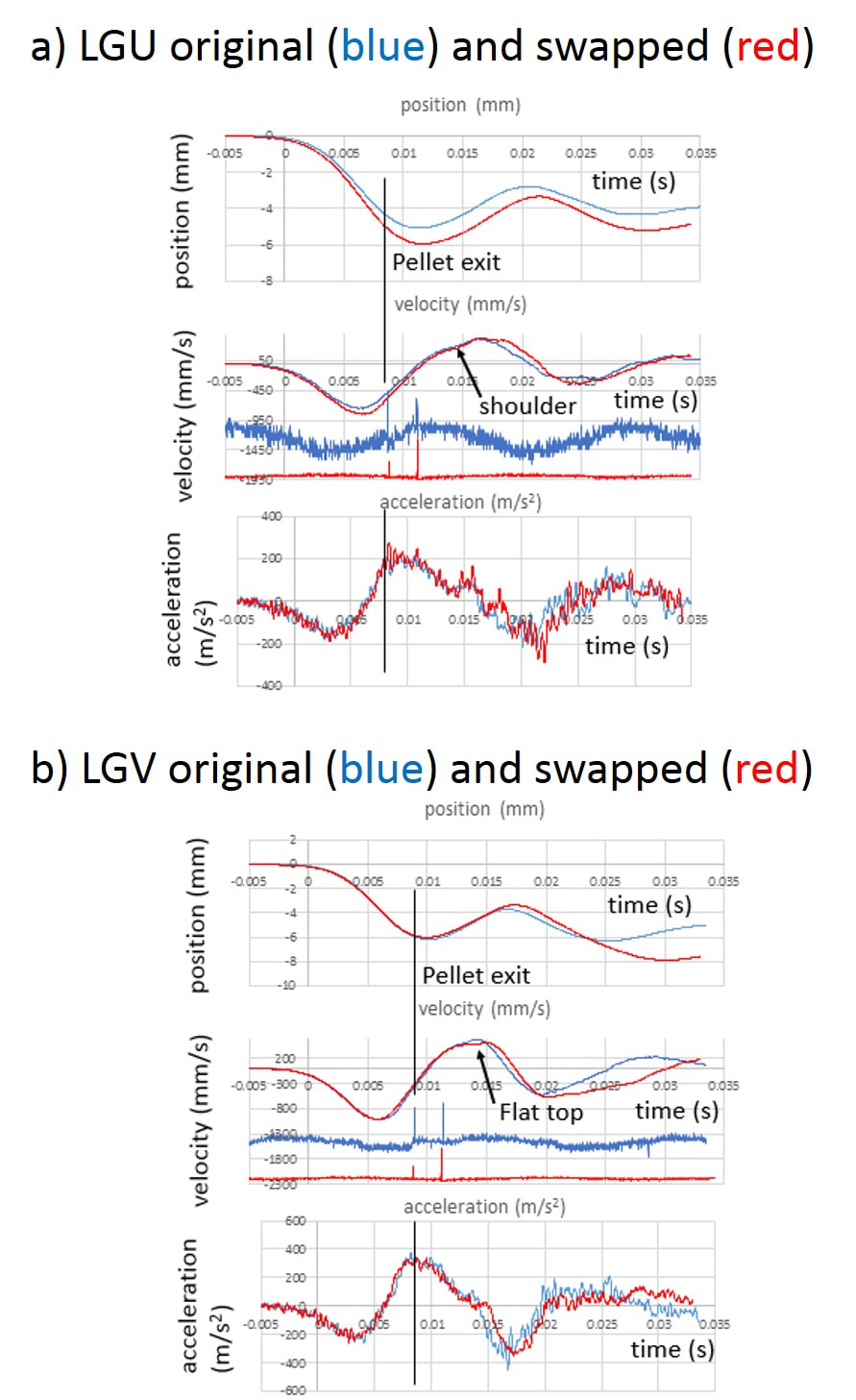

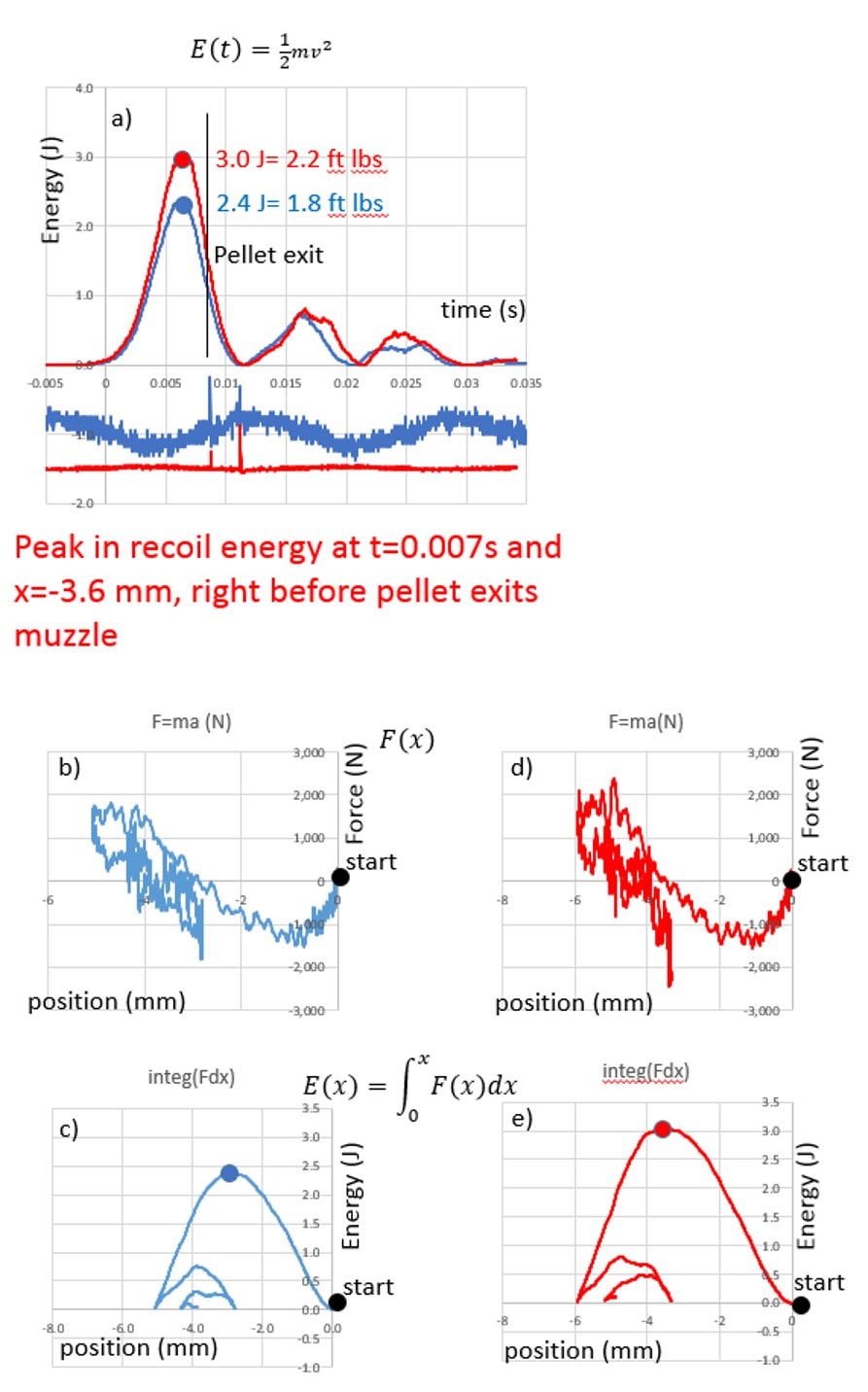

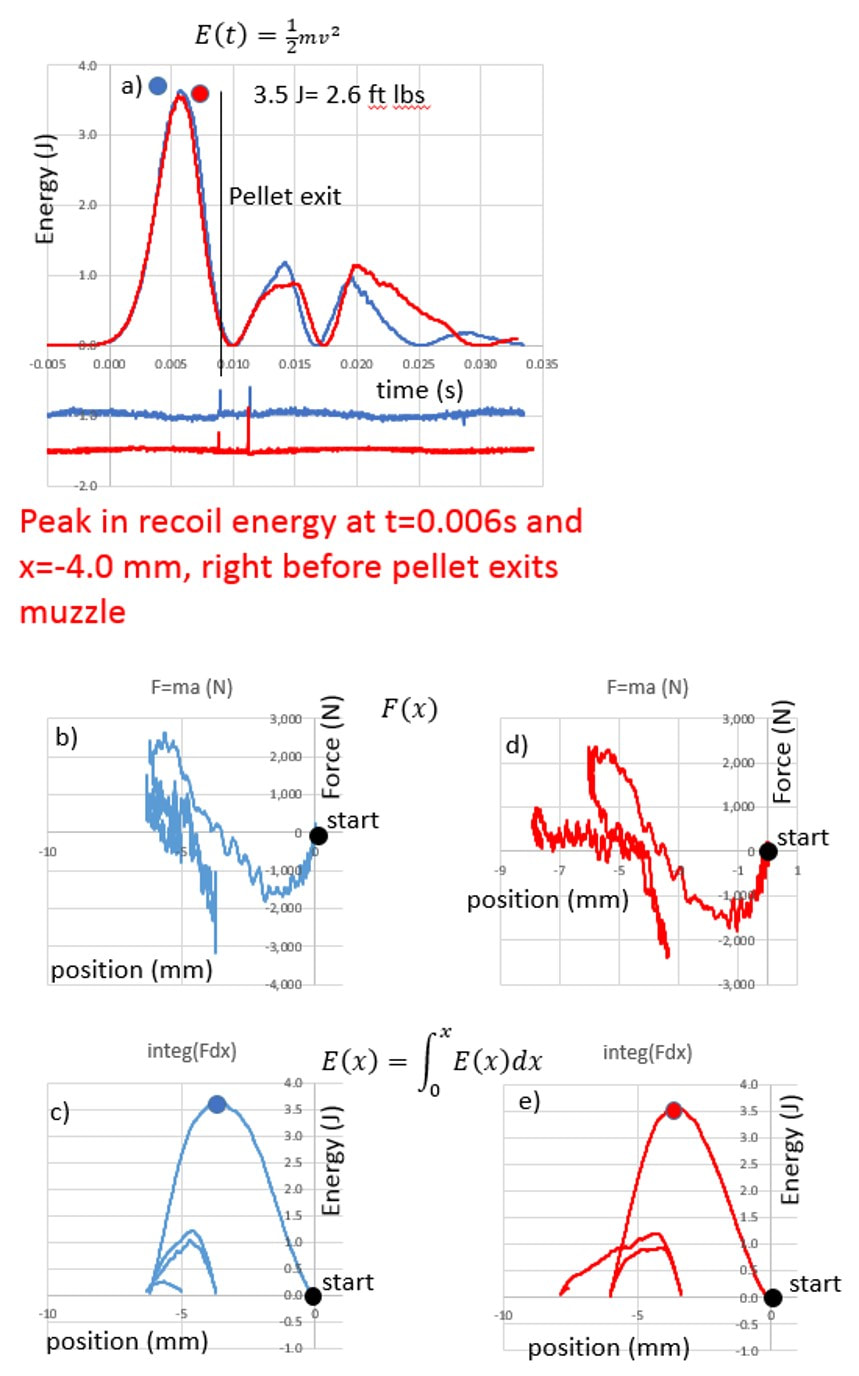

LGU/LGV power plant swap: How does changing power plants affect performance and does a longer offset transfer port make a difference?

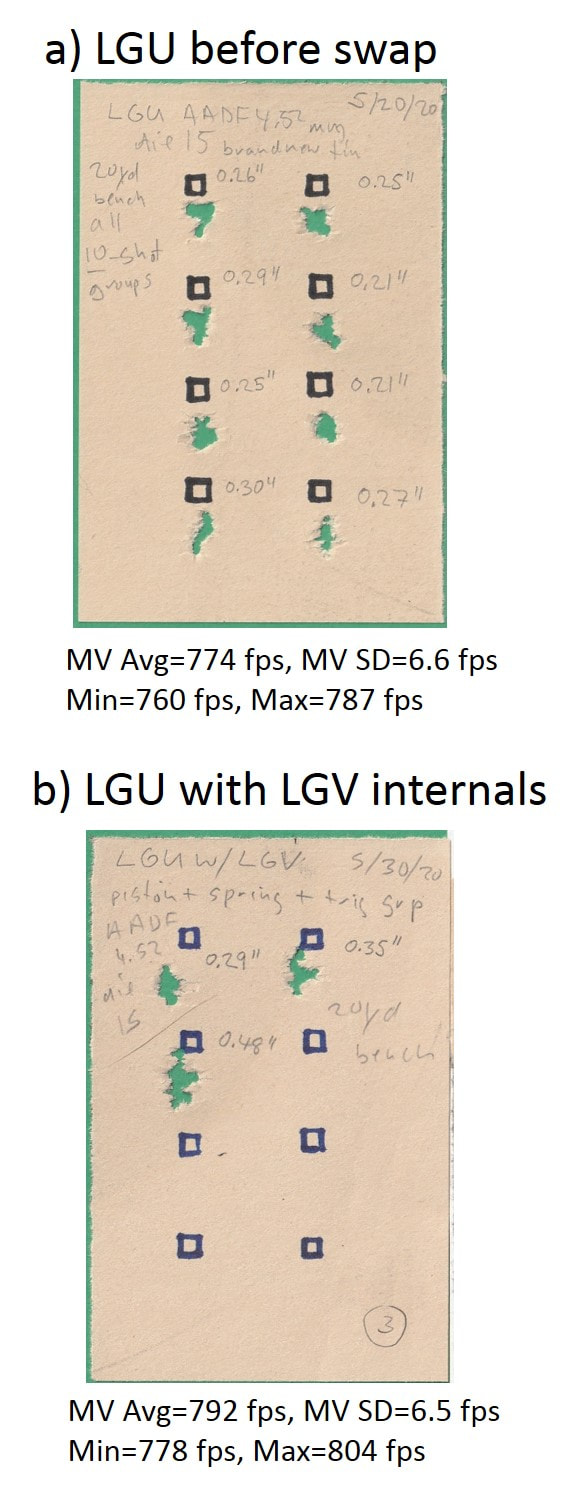

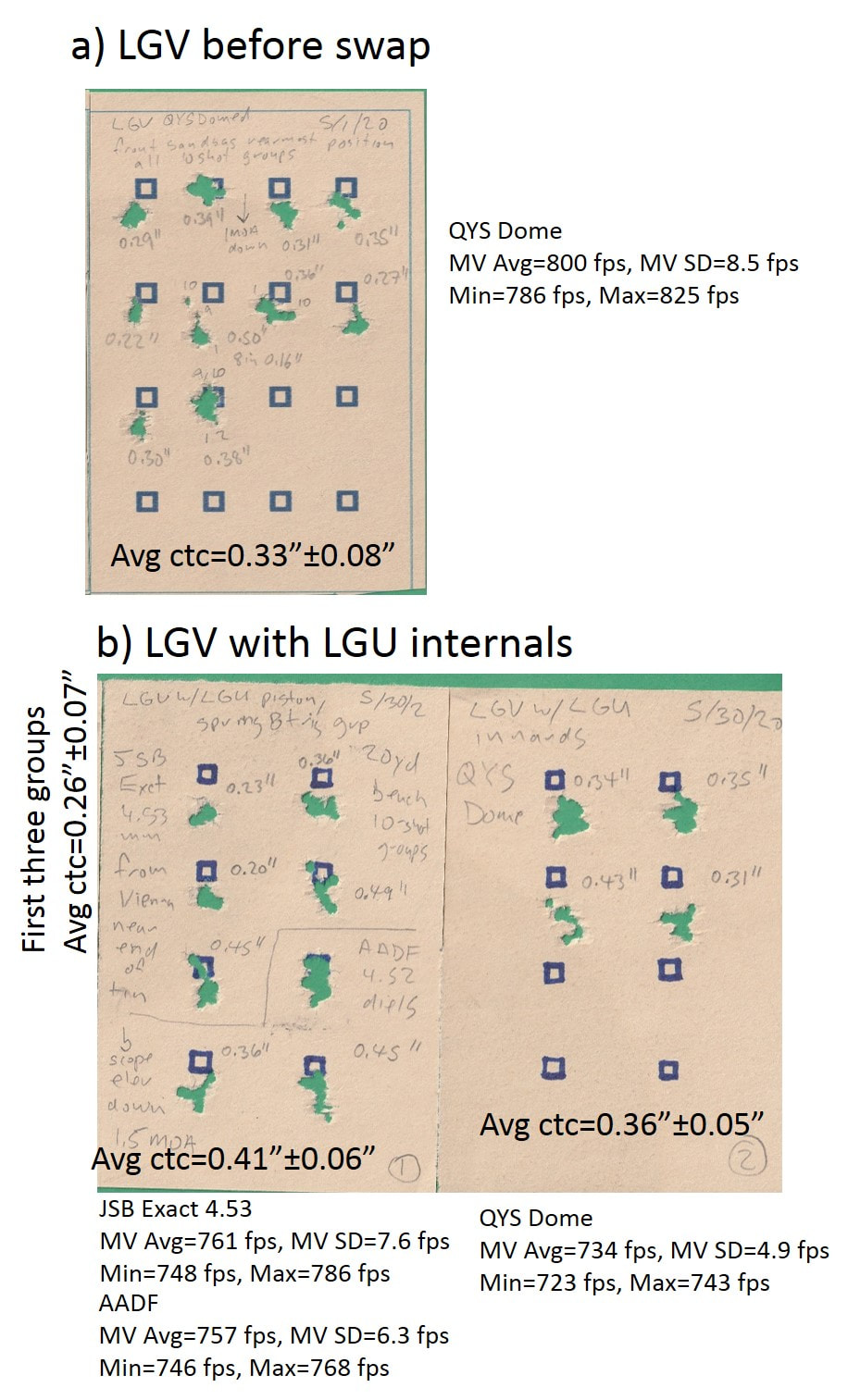

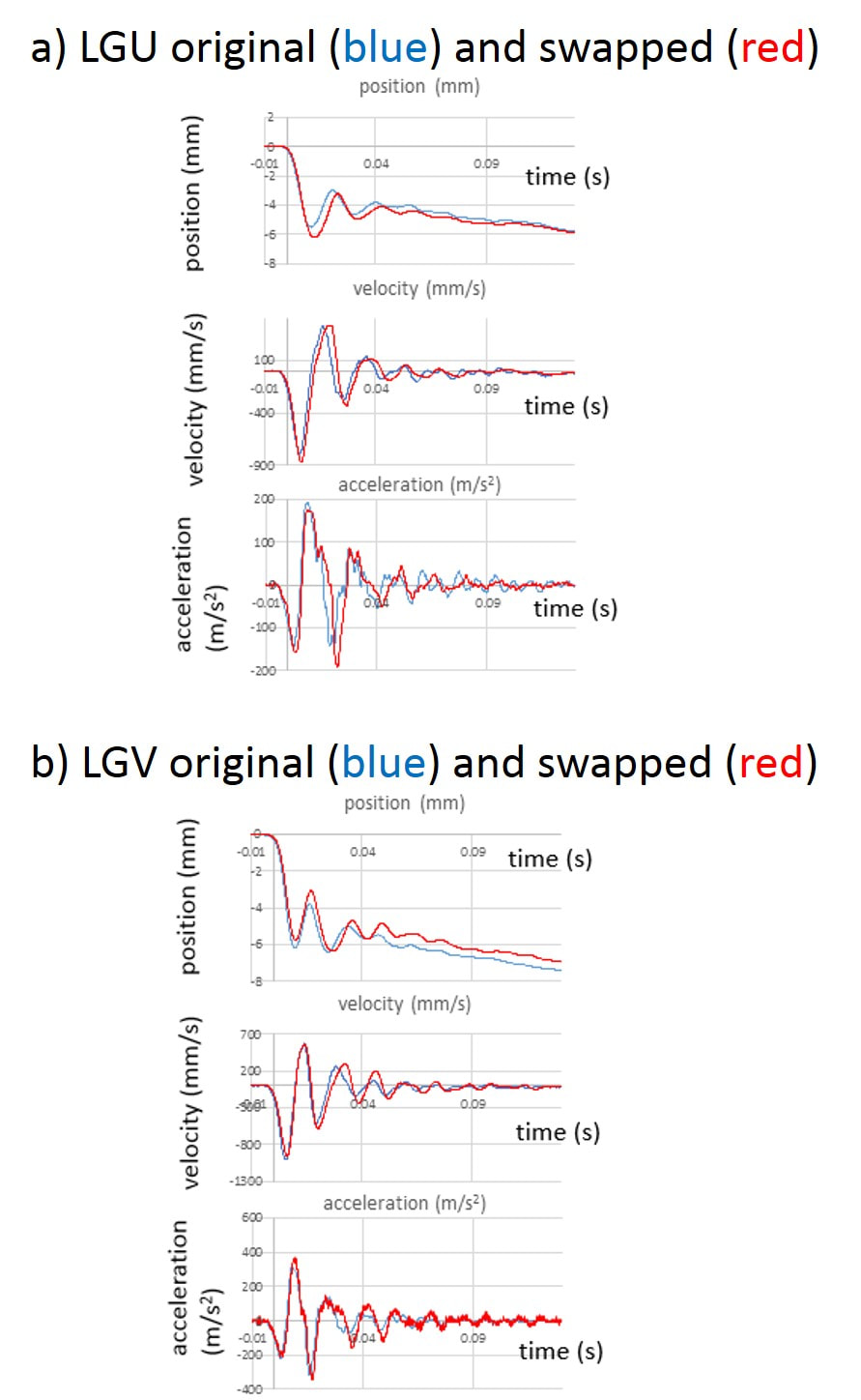

Figure 1 looks at the accuracy of the LGU before and after swapping its power plant with the LGV. Accuracy is better and velocity is about 20 fps lower before the swap. The standard deviation in muzzle velocity is nearly identical, suggesting that the consistency of the power plant does not depend on which rifle uses that power plant.

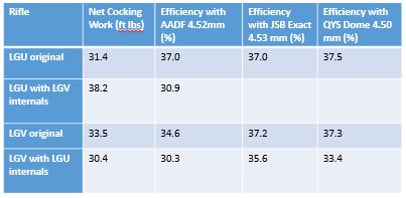

On the other hand, the ABP in the LGV produced the nearly the same peak recoil energy as the LGU piston and spring, but with a much higher muzzle velocity.

RSS Feed

RSS Feed