Conclusions: What does all this means?

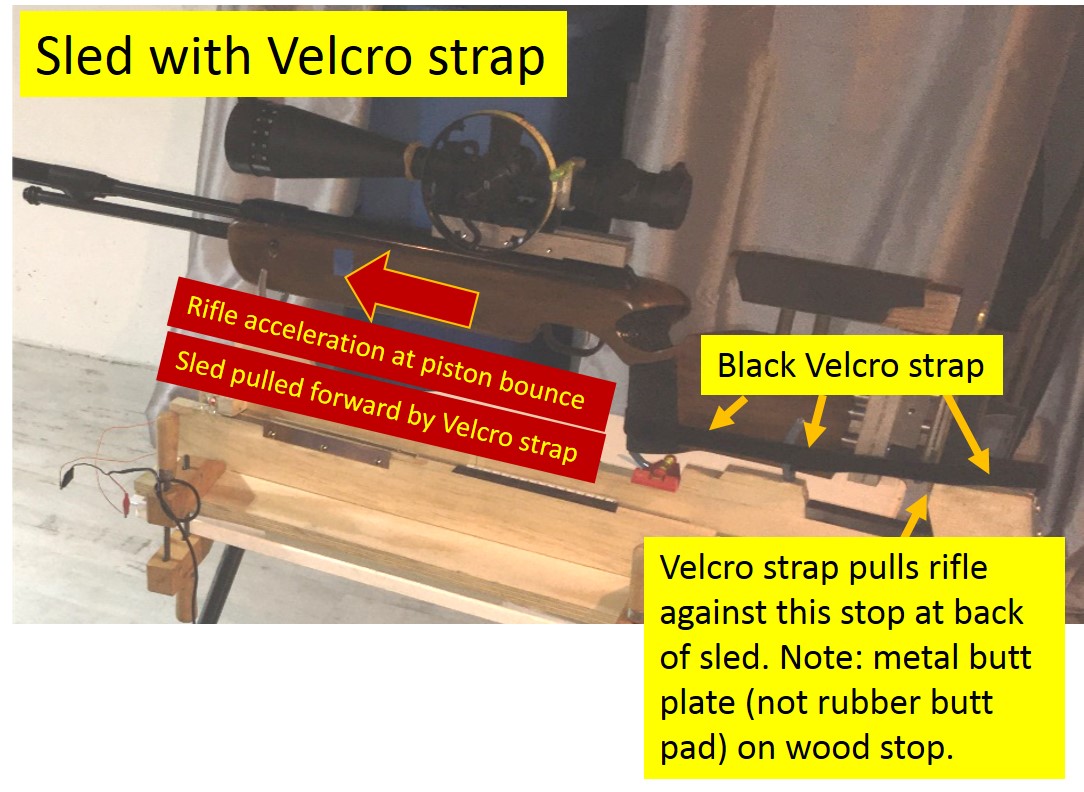

Figure 9.1 shows the original sled system. A metal plate from the butt of the rifle (not the rubber buttpad) pushes against a wooden stop at the back of the sled, so I think that the initial rearward acceleration of the rifle should transfer to the sled pretty well. However, when the rifle accelerates forward it pulls the sled with it using the black Velcro strap. At the piston bounce the forward acceleration of the air rifle is on the order of hundreds of gs. Remember that force equals mass times acceleration, so to get the sled moving forward and accelerating in unison with the rifle, the force on the sled through the Velcro strap needs to be hundreds of times the weight of the sled. If the sled were very light, it would be very easy to accelerate it forward with the Velcro strap, but since the sled weighs about 2.4 lbs, it takes hundreds of pounds of force to get it to accelerate forward.

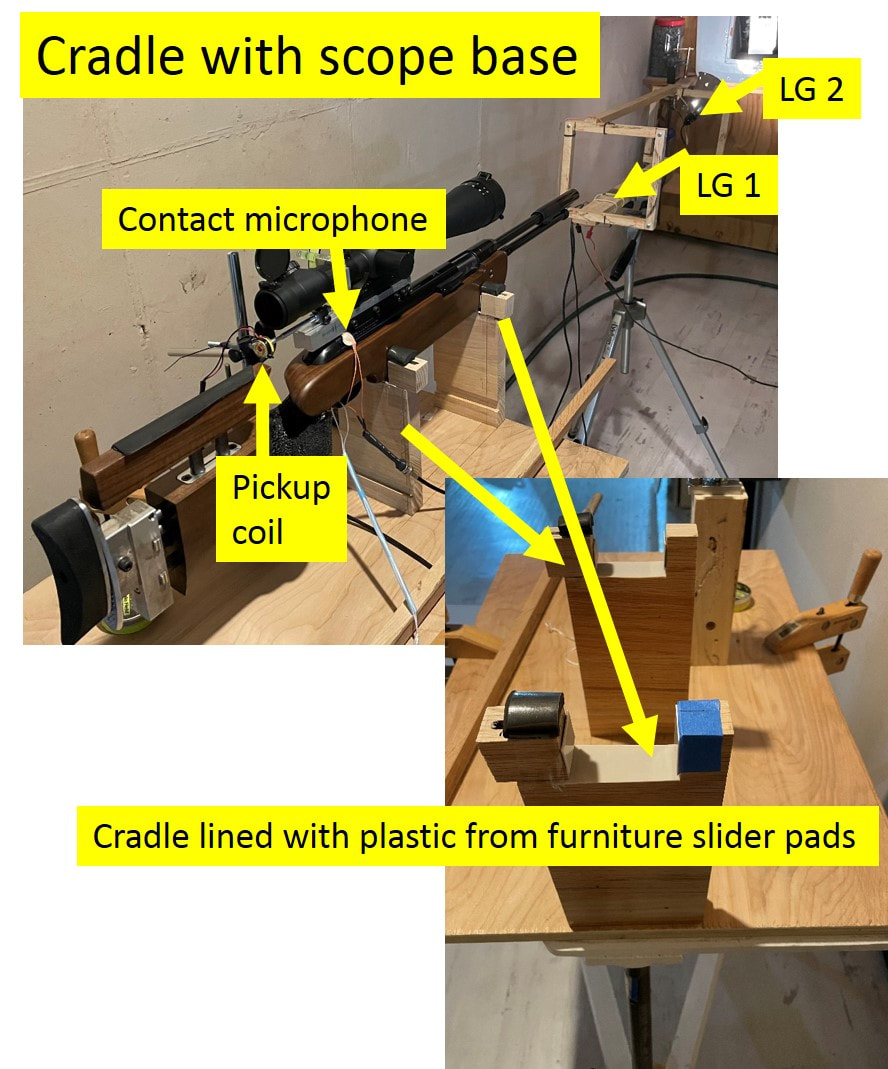

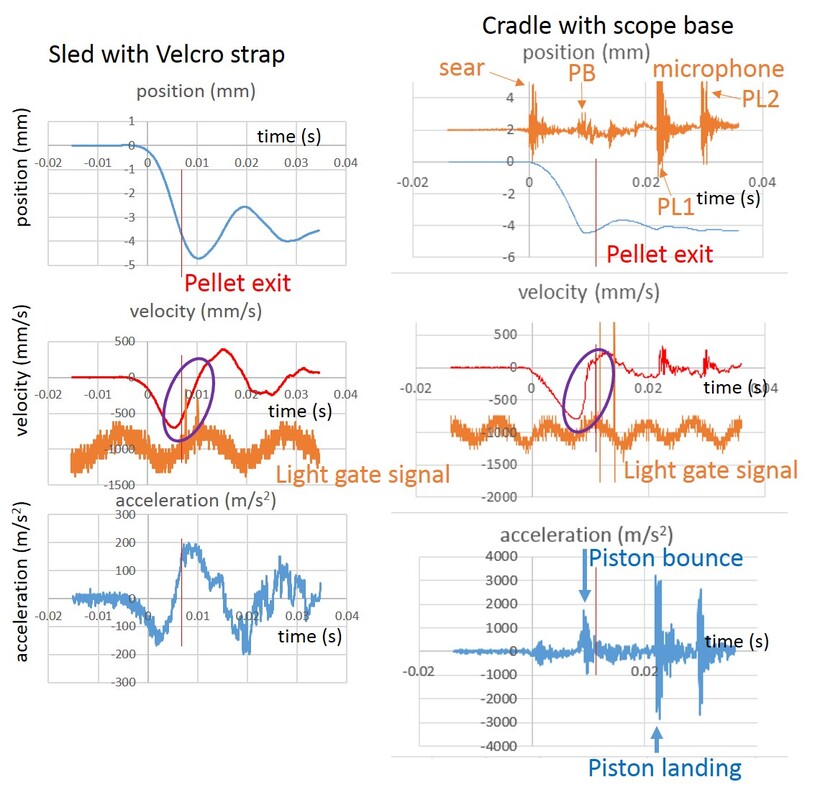

The red velocity traces in the middle of Fig. 9.4 also are similar, with an initial dip as the rifle and sled recoil backwards, a forward peak as the rifle and sled move forward, and some oscillations after that. The maximum rearward velocity of the sled is around 750 mm/s, which is similar to the value obtained using the cradle. This is probably due to the strong connection of the rifle to the sled when the rifle is pushing back. On the other hand, the first dip in the velocity with the sled is symmetric while the right side of that same dip is much steeper with the cradle system (see purple ovals in Fig. 9.4). Furthermore, the magnitude of the peak forward velocity using the sled system is about a factor of two bigger than with the cradle system! The most critical difference is that the pellet exit time with the sled occurs before the sled stops (v=0), while it occurs after the rifle stops using the cradle system. The reason for this is that with the sled, the rifle stops and starts moving forward well before the sled gets accelerated forward by the stretched Velcro strap. As a result, the sled stops after the rifle stops, so the zero in the sled velocity occurs later, after the pellet has exited the muzzle. The pellet actually exited the muzzle after the rifle stopped, but since we’re measuring the motion of the sled and not the rifle, we do not measure this correctly. This is probably the biggest problem with using the sled. The extra forward motion of the sled could be due to the stretched Velcro causing the sled to snap forward and hit the back of the rifle, giving the system a delayed, extra push forward. The lower friction of the sled could also allow the amplitudes of the position and velocity oscillations to be bigger compared to the rifle sliding with more friction on the cradle.

The bottom traces in Fig. 9.4 show the acceleration of the sled (left) and the rifle in the cradle (right). Here the differences are most dramatic. The slop in the connection between the rifle and the sled, especially when the rifle is going forward and relies on the Velcro strap to pull the sled forward, results in broader peaks and dips with much smaller magnitudes. The peak forward acceleration at the piston bounce with the sled is around 200 m/s2 while it’s closer to 1500 m/s2 with the cradle! Thanks to the new cradle data, we can see that the piston landing is more violent (louder, as seen in the top microphone trace, and with a bigger acceleration) than the piston bounce. I guess a cushion of compressed air is gentler in stopping the piston than the steel end of the compression tube! It's very helpful to measure the sound in addition to the velocity and pellet exit signals. The more we can measure the less we have to guess about what is going on!

The problems with the sled system will corrupt the recoil traces, especially the acceleration. However, since we use the same sled system to characterize and compare all three air rifles, the relative differences in recoil behavior can still provide insight into their behavior. Ideally, we would use the new cradle system for all these measurements, but that will have to be a future project.

Although I strive to learn from other people’s mistakes, I often learn more from my mistakes than from my successes, and this mistake has been very educational! My understanding of how an air rifle recoils and how to measure it has dramatically improved thanks the revelations that Steve made!

So here are the conclusions, finally!

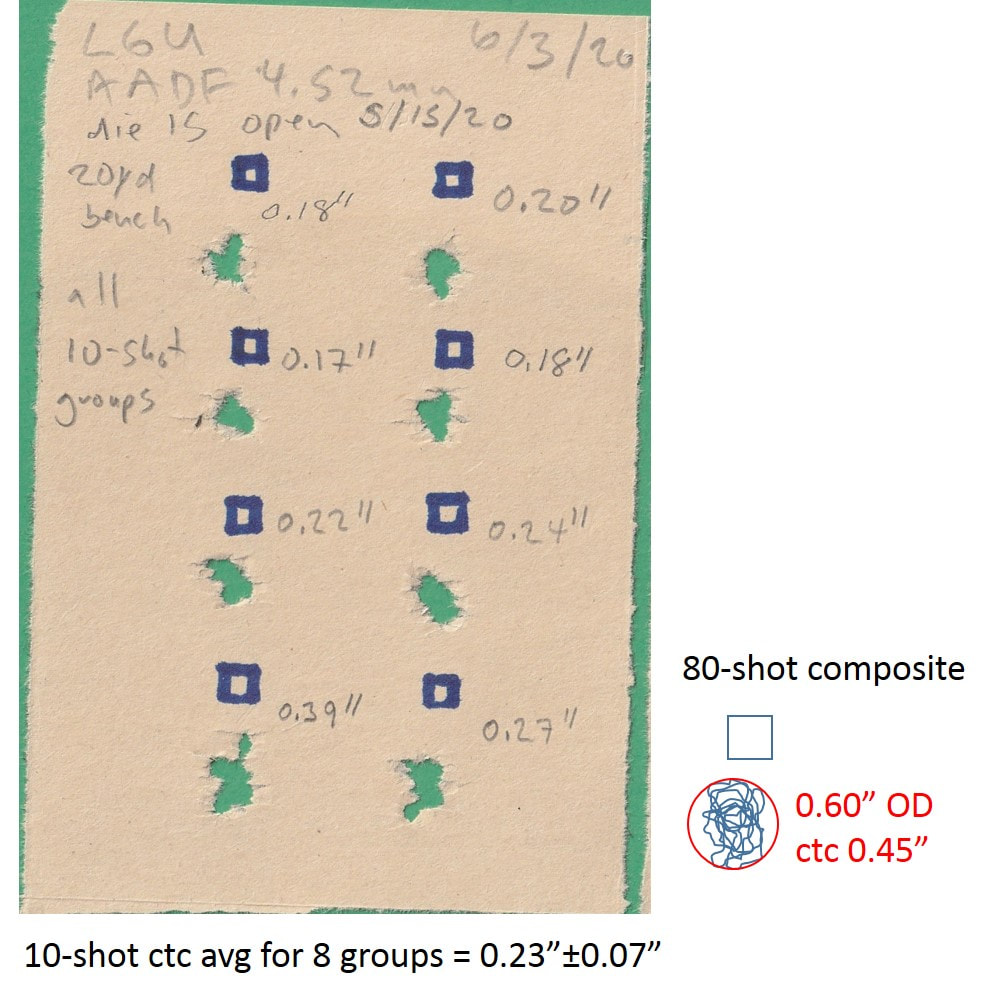

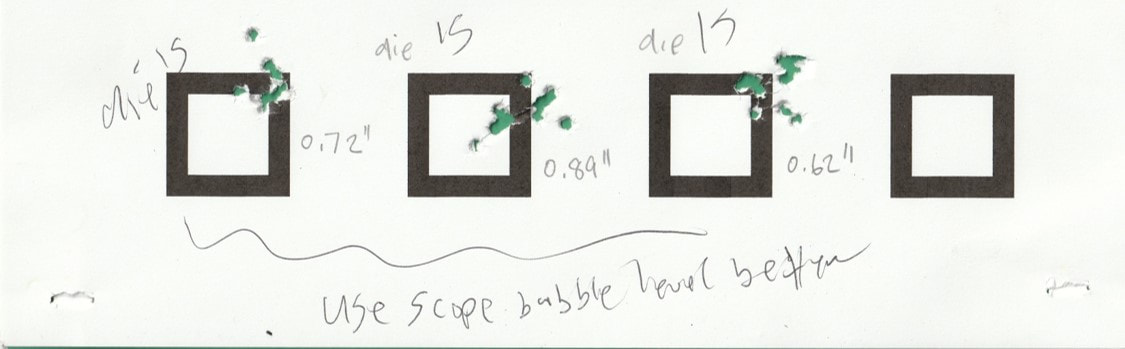

1. Airguns are fascinating! You probably wouldn’t have made it through the last eight chapters if you didn’t agree with this, but I have gained an even greater appreciation for the engineering and physics involved in air rifles. I’m still amazed that a bouncy mechanical system can put 10 pellets within a quarter inch of each other at 20 yards. The spread of pellet impacts corresponds to an angular separation of less than 0.02 degrees. That’s an angular resolution of 1 part in 18,000! Even more remarkable is the fact that my forty year old FWB 124, with its break barrel, can match the accuracy of modern underlever air rifles, built in this century! For a break barrel to achieve this kind of accuracy, the muzzle of the barrel needs to repeatably return to the same position within 0.006” when the barrel is closed. And this is done with a simple ball detent to lock the barrel in place. I wouldn’t be surprised if most barrels have a runout from one end to the other that is at least a few thousandths of an inch. This accuracy is achieved in spite of fairly violent recoil motion, with the rifle moving almost a centimeter back before the pellet leaves the barrel in the artillery hold. Figure 9.5 shows some of the best 10-shot groups that I have ever shot from a springer at 20 yards. In Fig. 9.6 you can see how my LGU did at 52 yards outdoors. The groups all have a similar POI, especially the first and third groups, which are right on top of each other. These groups would be pretty respectable for a 22 rimfire rifle, so I’m very happy and a bit surprised by the performance of my LGU at 52 yards.

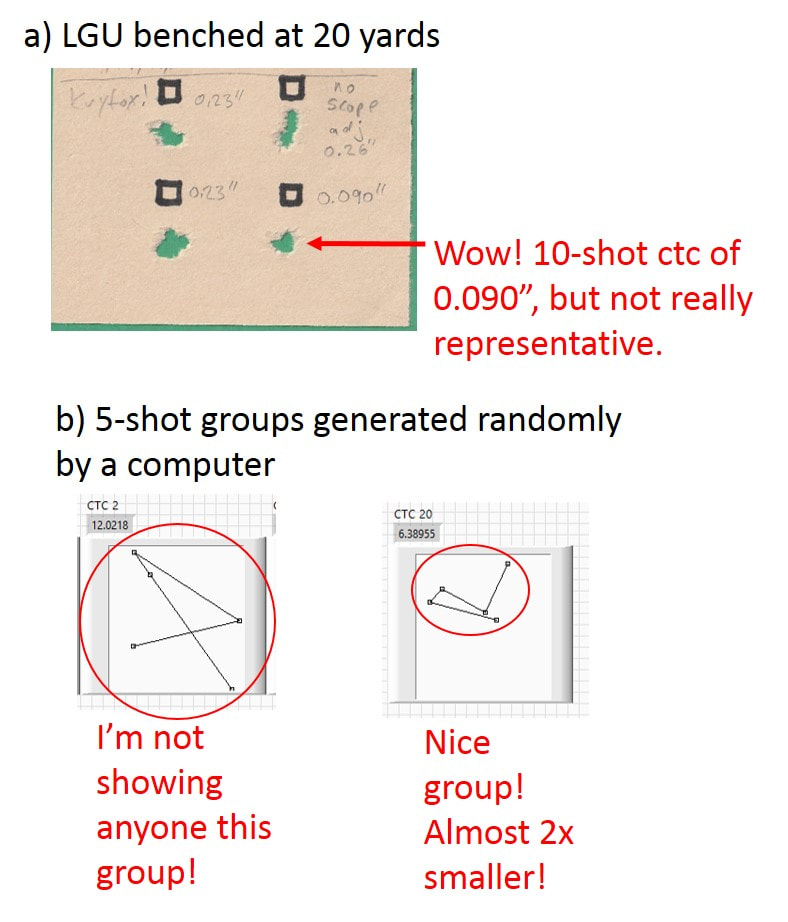

Figure 9.7a) shows four 10-shot groups at 20 yards from my LGU. The first three groups are pretty typical, but the last had a ctc of around 0.090”. This is pretty remarkable, but unfortunately does not reflect what I can normally expect out of this rifle. If we can get a remarkably small group for 10-shot groups, mostly by accident, the likelihood for getting a tiny but non-representative 5-shot group is even greater. Figure 9.7b) shows largest and smallest five-shot groups out of a total of twenty groups that were generated completely randomly on a computer. One can pretty easily get a difference of nearly a factor of two in group sizes for purely random groups, so when I get a super tiny five-shot group, I have to wonder if it may have just been luck.

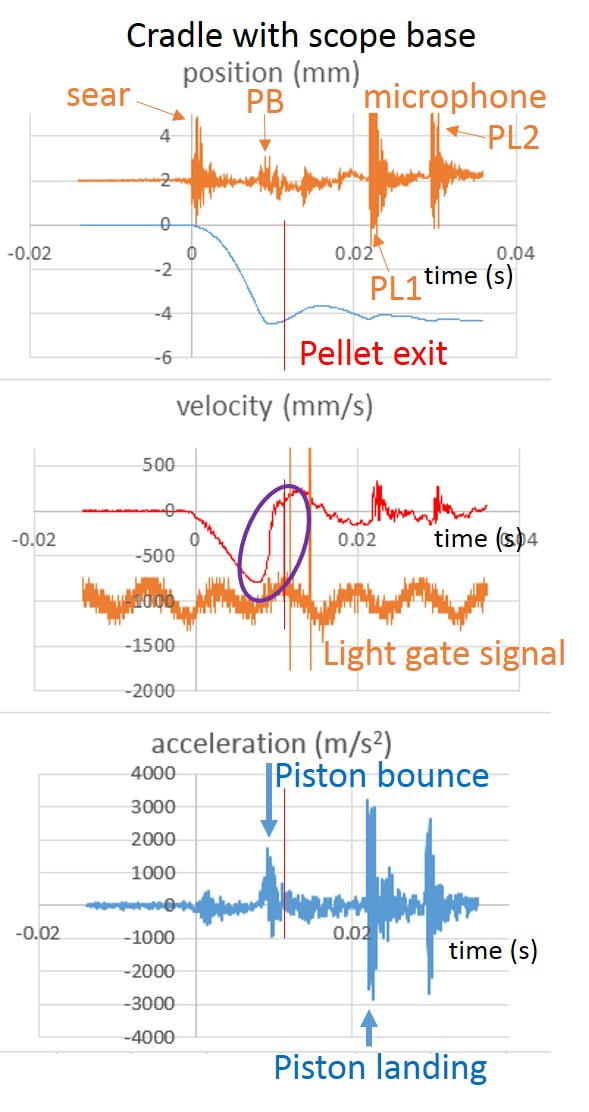

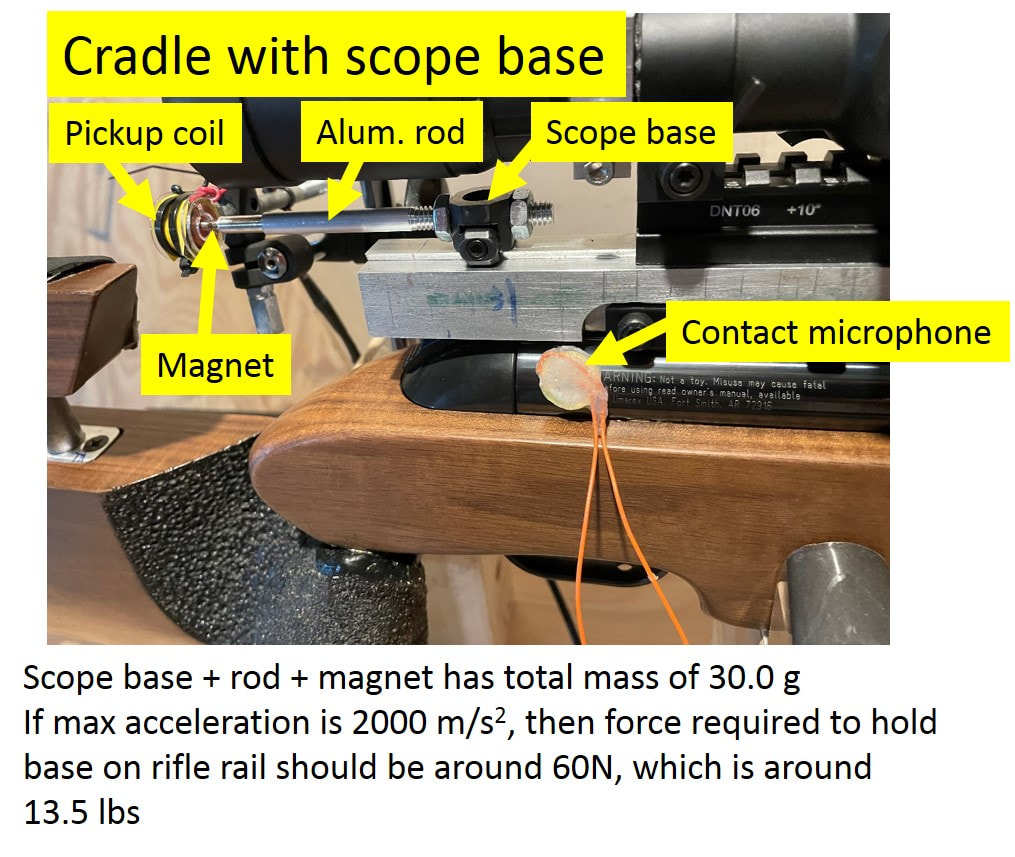

Figure 9.8 shows the position, velocity, and acceleration of an air rifle as a function of time. It also shows when the pellet left the barrel and records the sounds that the rifle made. There’s a lot of complex and interesting information here, but the challenge is to figure out what it all means!

I have greatly enjoyed and benefitted from talking with fellow airgunners from all over the world. A great example was my experience at my first Pyramyd Cup in 2019 (see Fig. 9.9). I was having some technical problems with new equipment and at the end of the first day of competition, many of the people that I was competing against spent their limited free time to help me. Several of these people were national and international champions in FT, so it was wonderful (albeit a bit embarrassing!) to have a group of FT veterans working with me to get the technical problems sorted out before the match continued on the second day.

I hope that you have found these chapters interesting and that they stimulate more discussions and new friendships!

JC

Aug/2021

RSS Feed

RSS Feed