1.- Swapping the trigger blades WILL invalidate the warranty of your rifle.

2.- ANY user intervention in the triggers MAY result in an UNSAFE condition. Once you get into the trigger you are on your own.

3.- I have no control of YOUR actions, so I can take NO responsibility for the results YOU get. This process proved safe and sound in MY gun. I cannot guarantee that it will be the same in YOURS.

Having said that to the satisfaction of the company's counsel, lets start:

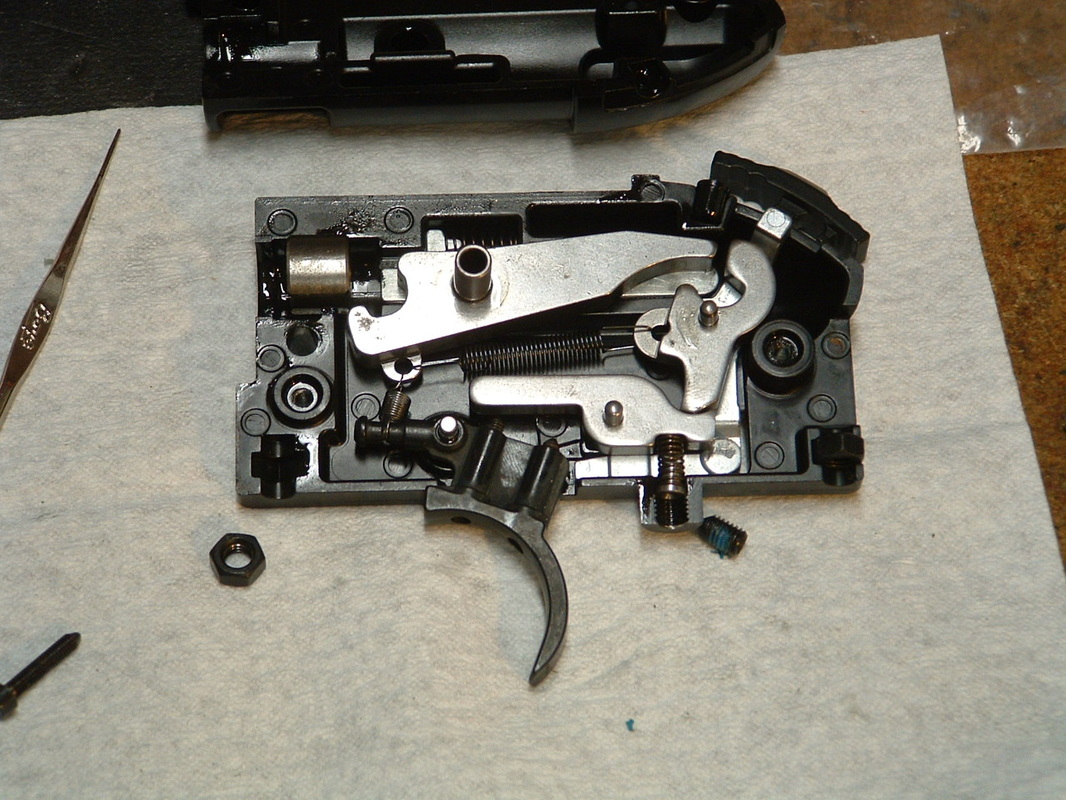

Following our initial experiments with the Walter LGU and its excellent performance, but horrible trigger; we decided to distribute the "Match Abzug" (or "Tuning Trigger") to all those that got their guns from Ct Custom Airguns free of charge. We saw no reason to have an excellent gun saddled by a hideous trigger . . . or so we thought! LOL! but more on that later.

The "Tuning Triggers" were obtained and mailed to all, but time precluded the real effort of creating a detailed swap-guide for people that are not experienced tuners till yesterday, when we could afford the time and tranquility needed to tackle the operation with the mind set of a beginner. Those of you that are experienced airgun tinkerers will have to bear with me and if I go too fast, then those that have questions, do feel free to post them as comments to this entry.

SO, here we go.

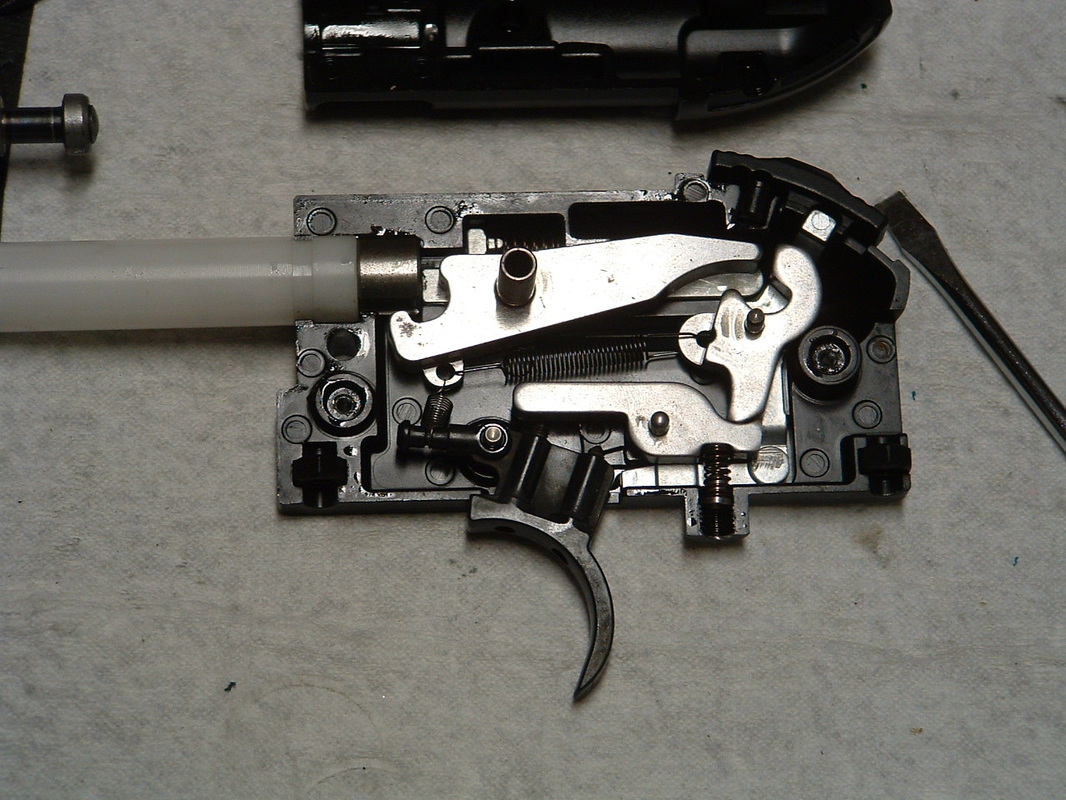

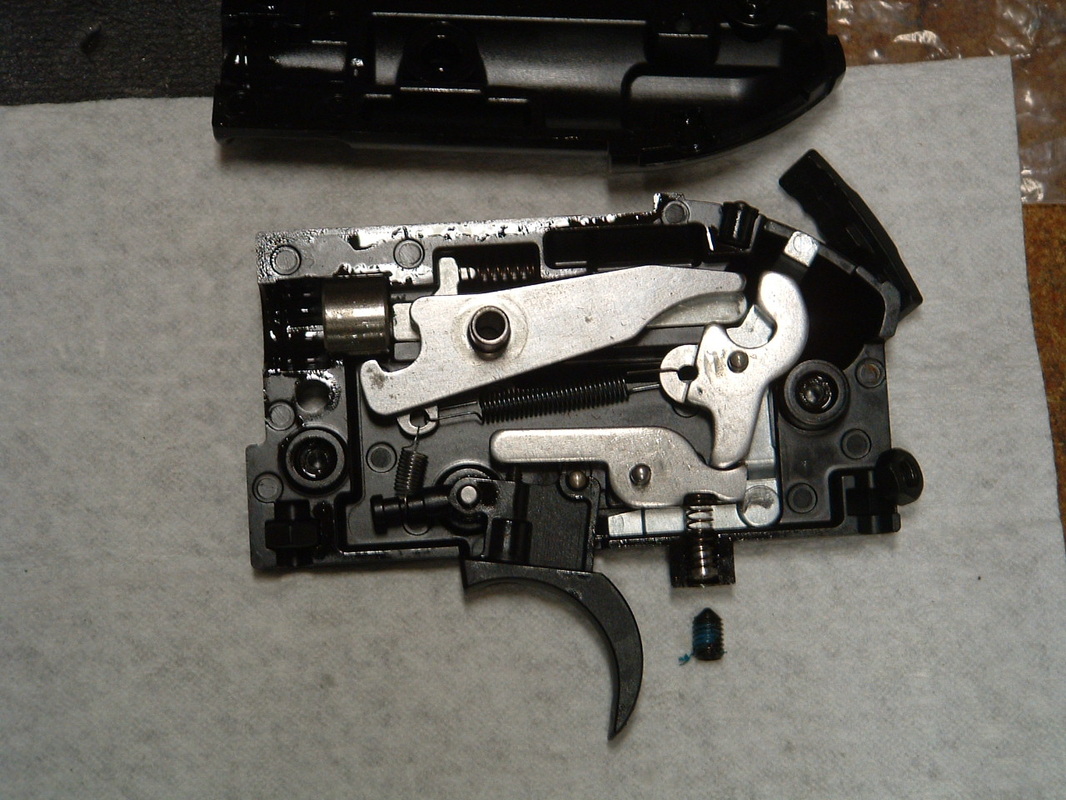

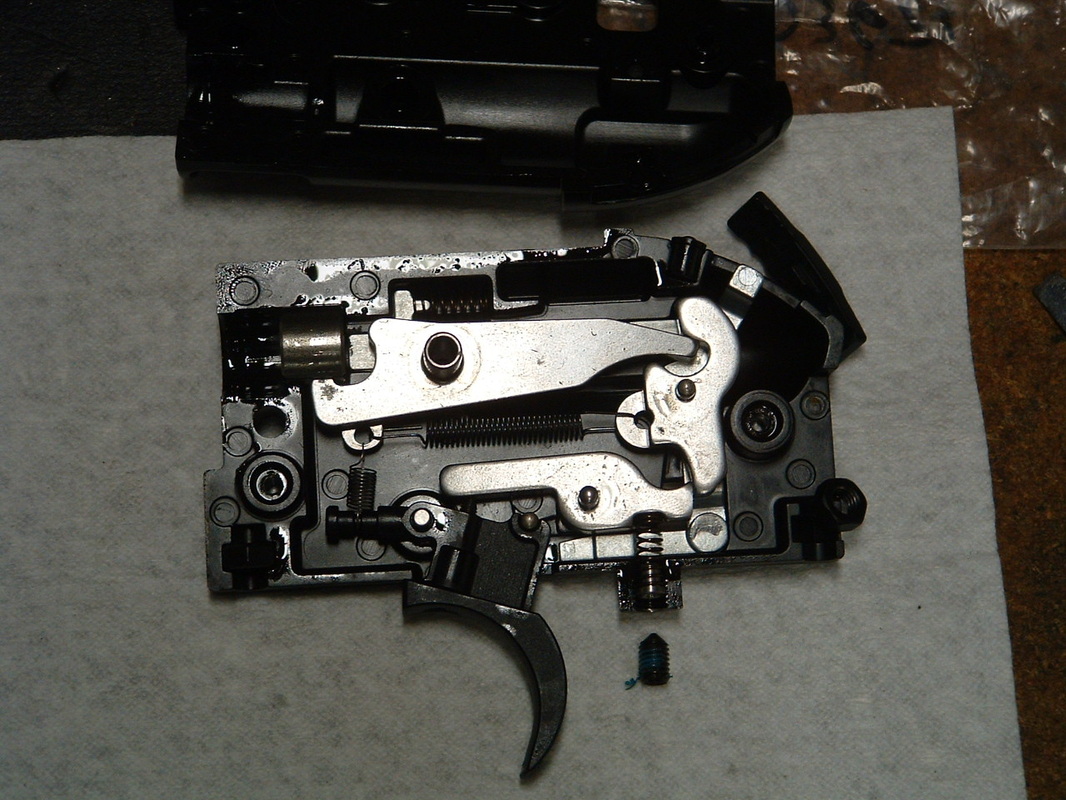

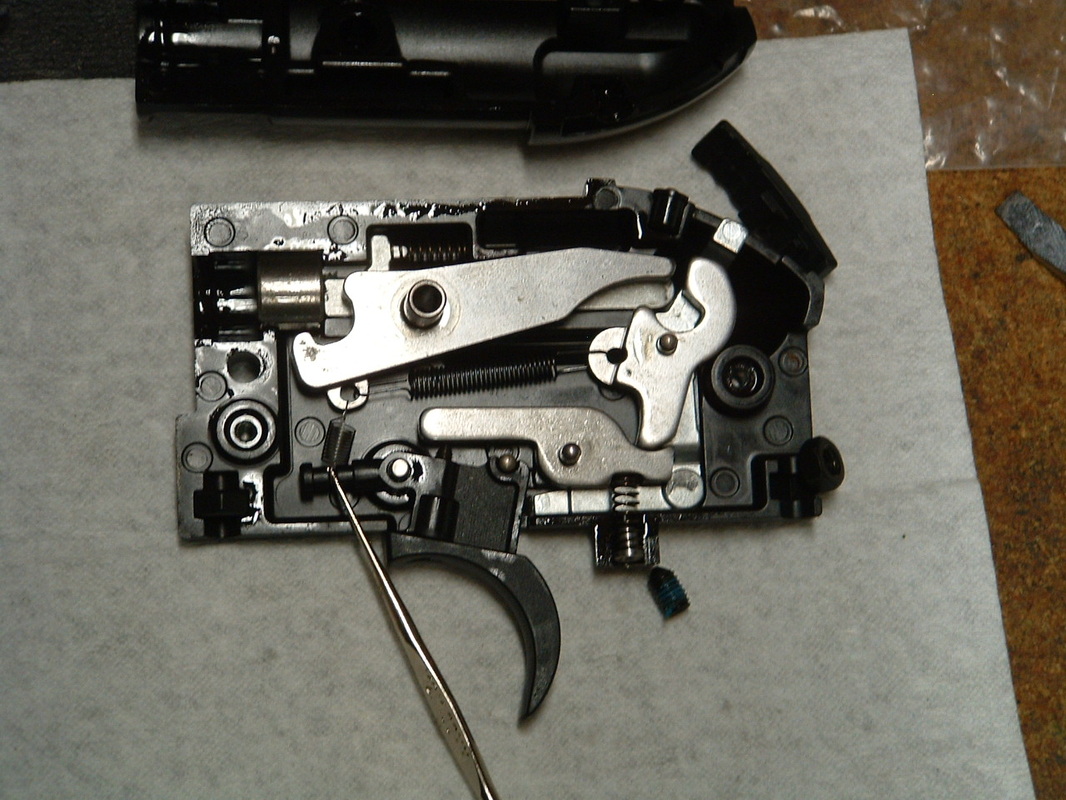

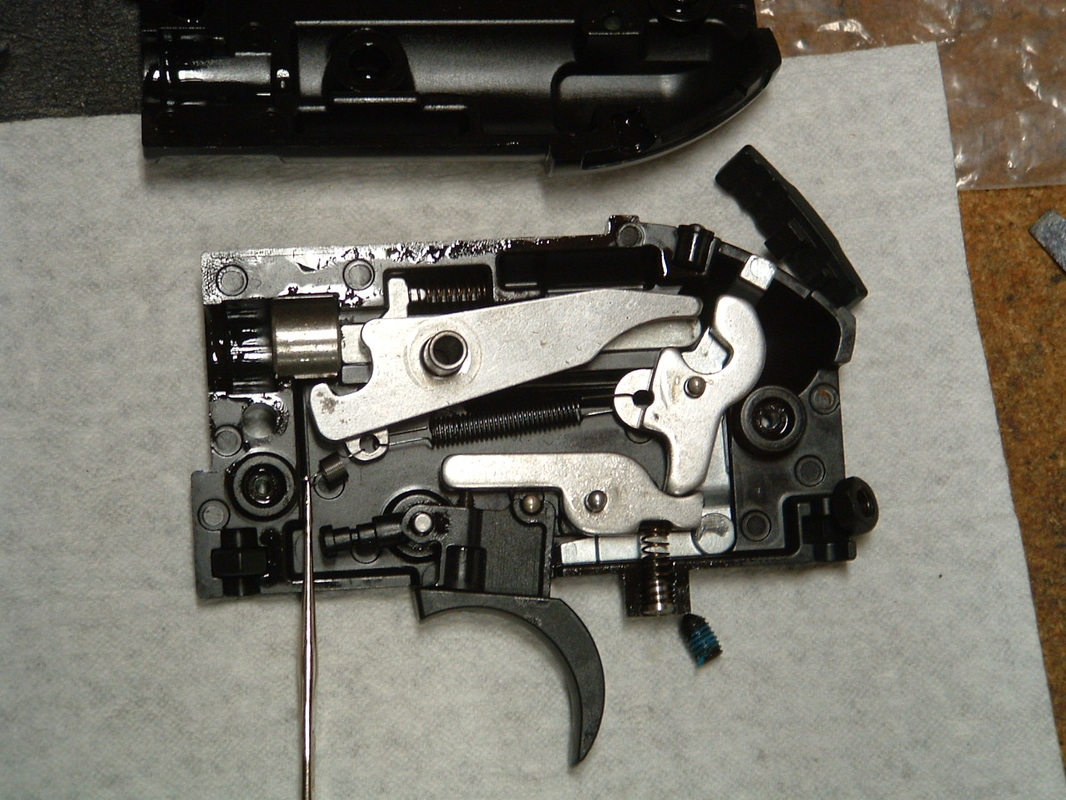

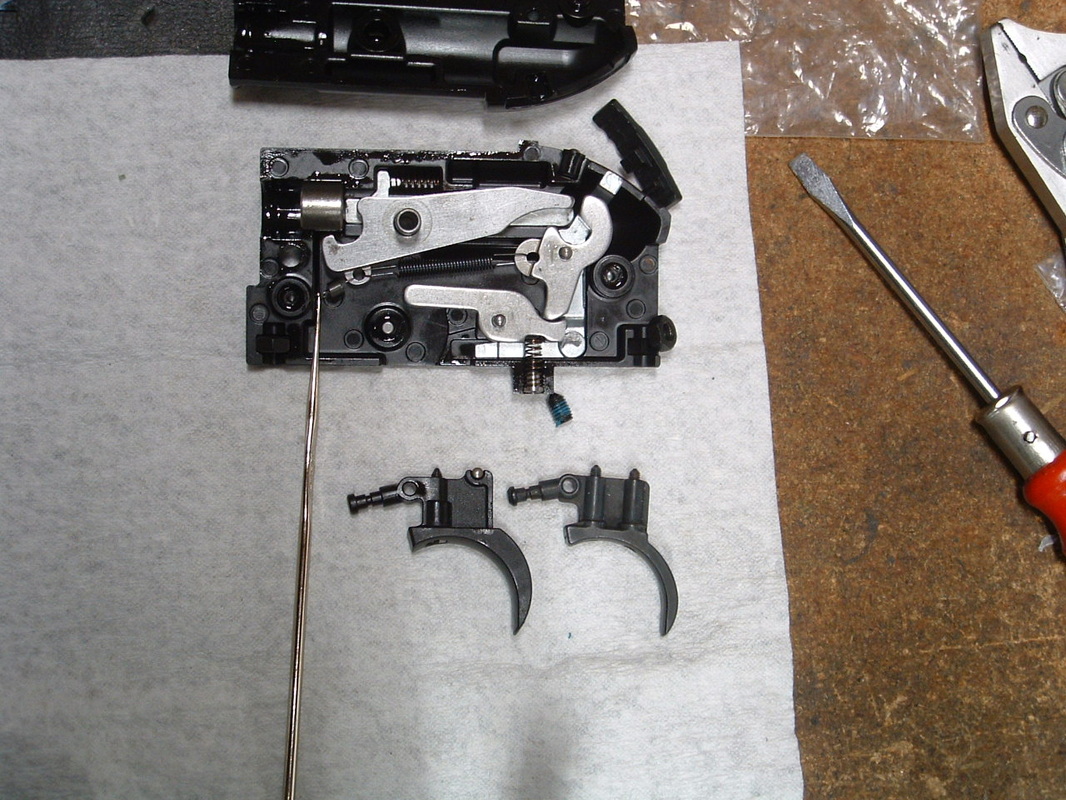

Tighten to something between snug and slightly tight and use thread locker, the blue one that is "medium strength" to make sure that the whole housing will not vibrate loose, open, and dropping trigger parts all over the field.

From here, just follow the reverse procedure to put your gun together.

Make sure that you insert the piston into the compression chamber BEFORE you insert the compression chamber into the gun.

Make sure that the Top Hat and Thrust washer are inserted into the spring and guide respectively.

Make sure that you release the anti-beartrap safety when re-inserting the compression chamber.

Make sure you align the compression chamber to the slot in the action for the cocking lug. NOTE that the cocking lug is held onto the compression chamber by a claw that has no hook. It is held in place by the location of a plastic runner that rides on a slot in the stock. The stock is, therefore, a MECHANICAL component of this gun.

Once you have everything together, cock the gun and holding the cocking lever firmly, make sure the trigger fires. Re-cock and fire several times. Once you are satisfied that the trigger unit is working well, then de-cock the gun and head for a test range.

You will need to fire the gun at least 50 times before attempting to reach the final adjustment of the trigger screws. If you polished the lever surface and the trigger screws discussed above, then you can start adjusting, but if not, do not worry, surfaces will become "burnished" by each other and you probably need the trigger time anyway.

Once you have fired the gun at least 50 times, you will need to start screwing IN both screws: first the front and then the rear.

Screw them in by ¼ turns, you will see how the trigger release becomes lighter and crisper. Lighter and crisper.

Adjust till you have the letoff you want.

The adjusting was tougher than the swapping, but once done, you're good for a substantial number of shots. You will have to adjust the fine details after every 1,000 and then after every 5,000 shots, or thereabouts.

HTH

Un abrazo!

Héctor Medina

PS.- in the next blog entry we will tackle what can be done to the PLASTIC trigger blade to make it a good trigger blade.

RSS Feed

RSS Feed