Part 2: Akin Minds.- HT Tuning

With the rifle set up, Hector conducted his own series of tests just to verify what setting it would prefer on target. Once complete, he reached out to me to see if I would be willing to continue with this testing. Hector said that he would like to keep the rifle set up just the way he had it for my first phase of testing. After discussing the terms of this testing I agreed without any hesitation.

A few days later the rifle arrived. For this testing you would think that the equipment would consist of an old beat up stock and parts that were laying around in Hector's shop. After all, it would be packaged and shipped to my shop, plus be assembled and adjusted throughout the testing, and finally disassembled packaged and shipped back to Hector.

Much to my surprise when I received the package, I found an exceptionally well packed rifle in a padded hard case, with precisely cut out areas for each item.

Included were a Vortex 6-24x50 Diamondback Tactical, a custom parallax adjustment wheel, an accurized ZR mount, and the most beautifully detailed D54 stock I have ever seen. Wrapped over the stock was a padded leather cheek piece...very nice!

The first time cocking this rifle was eye opening. Even though it is short stroked, the cocking cycle utilizes the full swing of the handle due to the modified fulcrum. The cocking effort is incredibly light!

Unlike the factory set-up, the internal metal frame of the stock had been removed, and the action was solidly mounted on self leveling metal washers (no more rubber washers). With this set-up, there is an added bit of stability and smoothness that you can feel in the sled action. Additionally, unlike the factory rubber washers, where you have to be more critical of the stock screw torque (which I usually set at 10-15 inch pounds), you can now torque to 25+ inch pounds and quickly get a repeatable, smooth feel on the sled. The ability to disassemble and return to the exact same setting increases quite a bit with this set up.

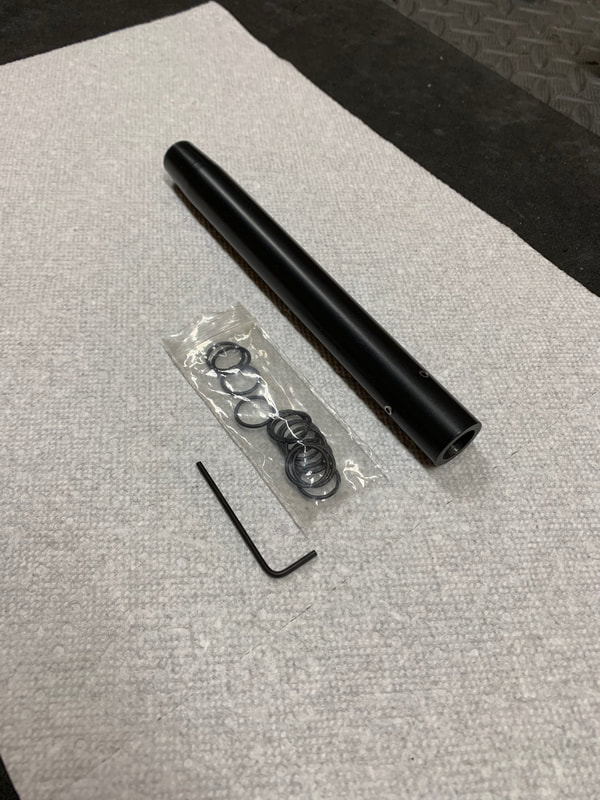

Here are some pictures showing the details of the HT, along with some comparisons to the factory muzzle weight.

The HT includes the tuning device, o-rings and an Allen wrench.

On to the testing

Summary of testing guidelines;

Testing was conducted across the entire adjustment range of the HT, one o-ring at a time from 0 to 10. After each adjustment was made, I shot 3 shots into a scrap bullseye, then 5 into the dedicated spot for each phase of the test (11 spots in all, plus a scrap spot for the 3 shots between each test)

The distance for this testing was 32 yards.

Pellets used for both tests were the JSB Exact 8.44 grain (4.53 head size). All pellets were from the same tin, unlubed, unweighed and unsized. Straight from tin.

The biggest challenge in this testing was seeking out calm days when there was no wind. On one of the test days this required a 4:45am start time.

28mm x 76mm HMO HT Test Results

Diana 56TH .177

28mm x 76mm HMO Short Stroke

JSB 8.44 Exact - 11.29 fpe

32 yards

Average c-t-c = .397"

Best group - .166"

Difference between largest and smallest group size - .502"

3 groups under .300" (in Bold)

# of o-rings / group size c-t-c

0 / .287"

1 / .409"

2 / .302"

3 / .361"

4 / .385"

5 / .654"

6 / .465"

7 / .668"

8 / .380"

9 / .166" Best

10 / .294"

For the next phase of testing I installed my AGT 22mm Skirtless Powerplant

AGT 22mm x 96mm Skirtless HT Test Results

Diana 56TH .177

AGT 22mm x 96mm Skirtless (stroke shortened by 9mm over the factory 105mm)

JSB 8.44 Exact - 11.40 fpe

32 yards

Average c-t-c = .366"

Best group - .215"

Difference between largest and smallest group size - .312"

4 groups under .300" - (in Bold)

# of o-rings / group size c-t-c

0 / .452"

1 / .215" Best

2 / .299"

3 / .461"

4 / .405"

5 / .241"

6 / .382"

7 / .305"

8 / .527"

9 / .285"

10 / .449"

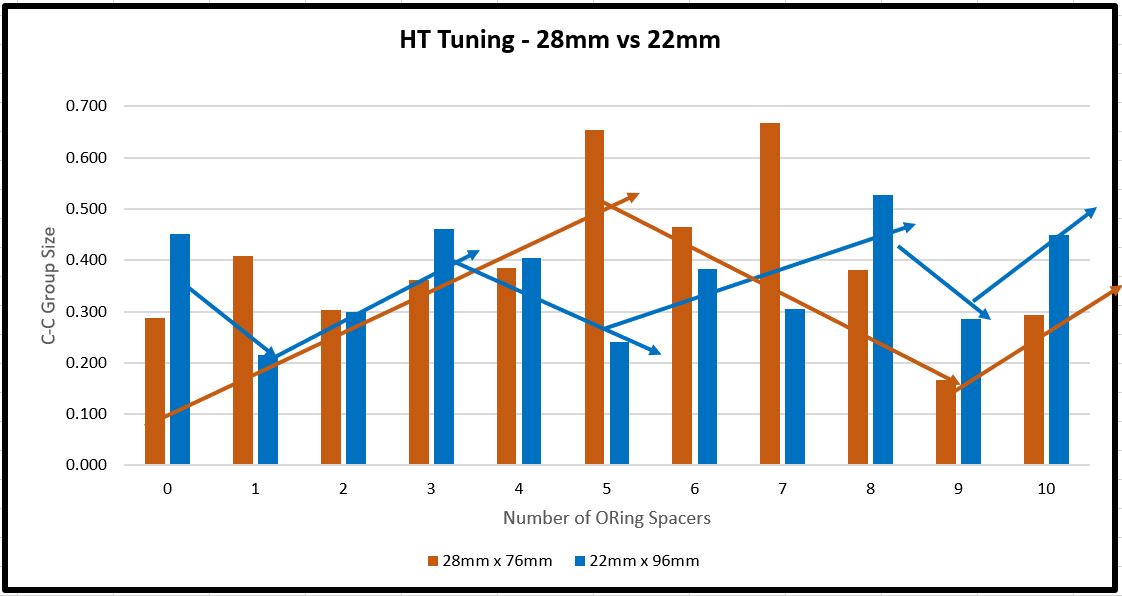

Here is a chart showing an overview of the testing outlined above, each set of bars corresponds to ONE pair of groups: the Ochre fired with the 28X76 mm's, the blue fired with the 22X96 mm's BOTH groups fired with the specified number of spacer ORings in the HT.

While I was doing this chart I saw a pattern to both tests that I did not notice before. Both tests have a sort of rolling pattern to them where the groups gradually increase, then decrease in size, and then start over again. Look attentively at the arrows in the chart above.

Ignoring the normal group to group variation that you would expect to see when shooting consecutive groups without making any changes, you can definitely see these patterns.

It looks like the 28mm set-up has a more pronounced climb from smallest to largest group sizes, and the 22mm has a less pronounced climb. This was reflected in my article and supported by the data. However, in the 0-10 o-ring range of testing, the 22mm had three cycles of this pattern, while the 28mm had only two. In my opinion this supports the theory of increased frequencies being produced by the 22 mm's kits.

The 28mm generates higher harmonics (as shown in the greater spreads from smallest to largest group sizes), but lower frequency (only 2 complete cycles of small to large groups in this testing)

The 22mm on the other hand made three complete cycles in this testing, indicating higher frequency. The peaks and valleys (group size differences) were lower so the harmonics were not as pronounced, but it occurred more frequently.

So, looking at this chart, I would bet that the targeted ranges for o-ring settings should be similar if you target the valleys (smallest groupings).

For example, on the 28mm the best settings could be either 0 o-rings or 9 O-rings (at this exact set-up, velocity, pellet, etc). A slight change to the set-up would require a new test, but results should be similar with 2 specific settings being revealed in the range of 0-10 O-rings.

On the 22mm set-up, you should find 3 valleys across the range of 0-10 O-rings due to the increased frequency of the harmonics.

This is VERY interesting!! I am theorizing that tighter groups in both tests would relate to the barrel being tuned to match an end point of muzzle movement with the release of the pellet.

28mm x 76mm HMO Short Stroke

The HT was very effective in tuning the 28mm x 76mm short stroked powerplant. You could see dramatic changes in group size with even the slightest change in HT settings. The size difference between the largest and smallest group was .512".

You could also clearly see when you were in the sweet spot ranges for the tuning (1-4 o-rings, and 8-10 o-rings). This powerplant did not like the range of 5-7 o-rings. This would be in direct relation to the barrel harmonics when using this particular powerplant, and at this particular power setting.

AGT 22mm x 96mm Skirtless

While I could see slight changes across the adjustment range of the HT, the overall effects of the adjustments were less. There is no doubt that a sweet spot could be found for dialing in for the smallest group, but the size difference between the largest and smallest group was only .312".

Further experimentation will be needed on the 22mm set-up. Now that the crown issue has been addressed, I will be following up with group testing using both the HT and the factory muzzle weight. This particular powerplant may very well prefer the added heft of the factory muzzle weight. Previous testing revealed .25" groupings at 49 yards on this set-up using the factory muzzle weight.

I hope you found this HT Testing interesting and helpful.

Up next will be an article that focuses on the two powerplants and some of the differences between them.

Steve

RSS Feed

RSS Feed