It took me a year to get back to these fine guns by request of a good friend of mine.

In the interim, we had imported the 12 ft-lbs kits directly from Germany, and results had been good with the LGU. But this friend wanted to have a "Matching Pair" of sub-12 Ft-Lbs guns. One built on an LGV, one on the LGU.

And so started our Odyssey.

I have posted enough info on tuning the LGU before, but I will try to outline those things that are different and important with the LGV.

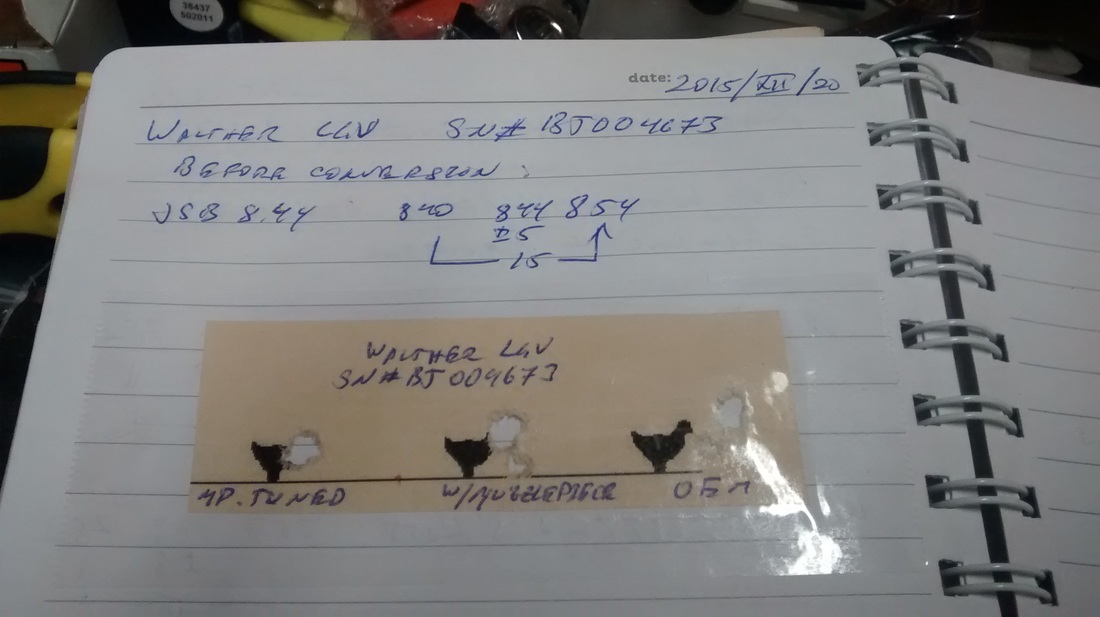

We start with a run of the mill 12 ft-lbs kit from Walther and the corresponding adjustable trigger:

There is no way of testing the accuracy of a gun without a proper sighting system, so a UTG drooped rail was machined to fit:

At 10 meters and full power, the gun was not keeping 10 shots inside the 6 meter chicken (rightmost group):

We sifted through our correspondence and found a cryptical allusion to a 'Hatsan Air Stripper' in one of my good friend Mark Bouchard's Emails.

And so I installed one of those "muzzle brakes" and proceeded to tune the center cone for the best possible group.

You can see how the group tightened from right to left.

After I was done, the gun was keeping all shots to the chicken's head. Not bad for factory part that was not even produced by the rifle maker! Thanks Mark!

And then we proceeded with the power conversion.

The pistons were extracted and compared:

Essentially, both pistons are identical in all aspects, EXCEPT construction. The 'new' pistons are a simplified construction version of the originals. Looking at the silver lining, our worries about the transfer port were abated a little.

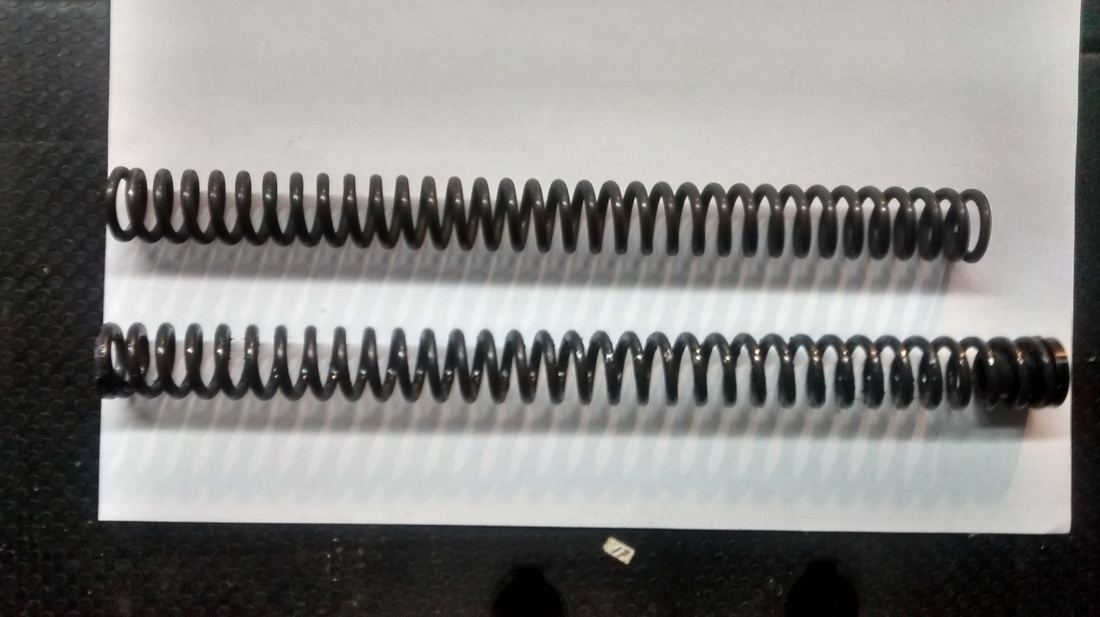

Then we measured and compared the springs:

There seemed to be little difference between one and the other. Not enough to make it develop 1.5 ft-lbs less.

Still, we decided to test the spring as it was delivered by Walther.

And sure enough we found a few things we did not like:

Power was high, about 13 ft-lbs which would make this illegal for FT, and the usual piston bounce-back and vibrations were there.

With the experience of the prior LGU tunes, we decided to cut off one full coil of the spring and install a composite TopHat that fit VERY tightly in the piston:

When cutting a spring, you need to forge and square the ends, otherwise ALL springs will kink and start giving problems. So, we forged and squared the spring's rear end.

Of course, this required the performance of the "stand-up" test.

A note here to support the use of the OEM greases. Walther provides two different greases: A larger jar of 'Piston Grease' (KolbenFett), and a smaller jar of 'Spring Grease' (FederFett):

The proportion tells you that Walther EXPECTS you to use 3 times more grease for the piston than for the spring. IF (BIG IF) the springs last about 15,000 rounds, then that means that you are expected to break open and make sure your piston is well lubricated every 5,000 rounds.

Maybe I should start working on an ORing'ed piston for these guns, but we'll se how it goes; for most people, 5,000 rounds is about a year's worth of shooting. So an ORing piston may not be completely warranted.

After the trigger swap, the gun is now shooting reasonably well and as soon as possible, we'll be testing it at distance.

If the short range groups hold, it will, indeed, be a sweet shooter!

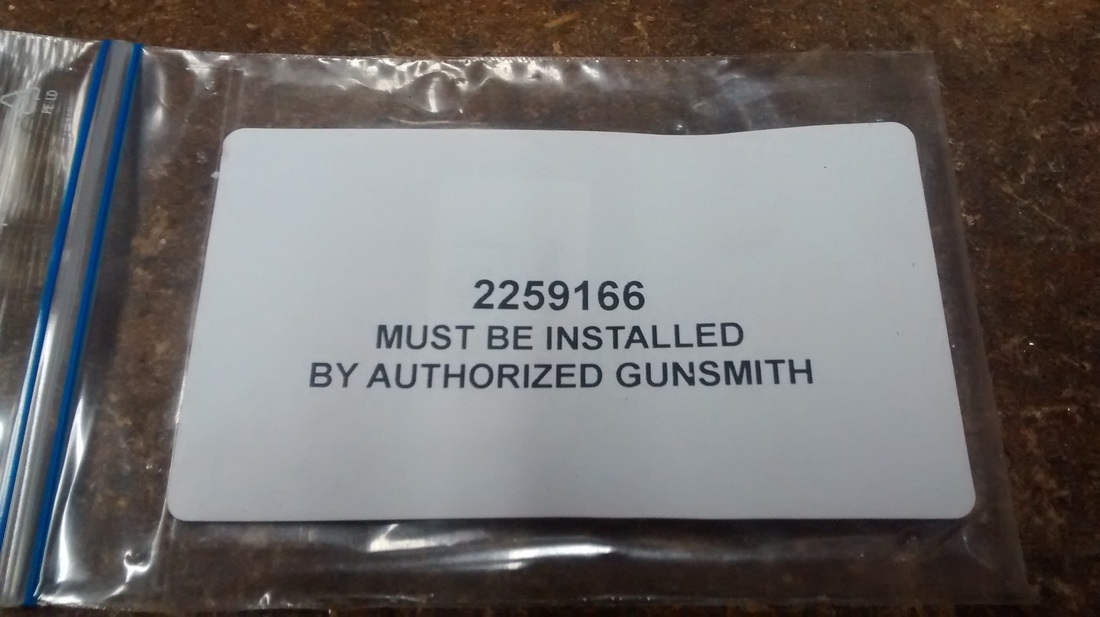

If I could have a Christmas wish granted, all shooters would heed Walther's admonition:

Keep well, shoot straight, and Merry Christmas to ALL!

HM

RSS Feed

RSS Feed