Chapter 2. How do the Walther LGU, Walther LGV and FWB 124 compare?

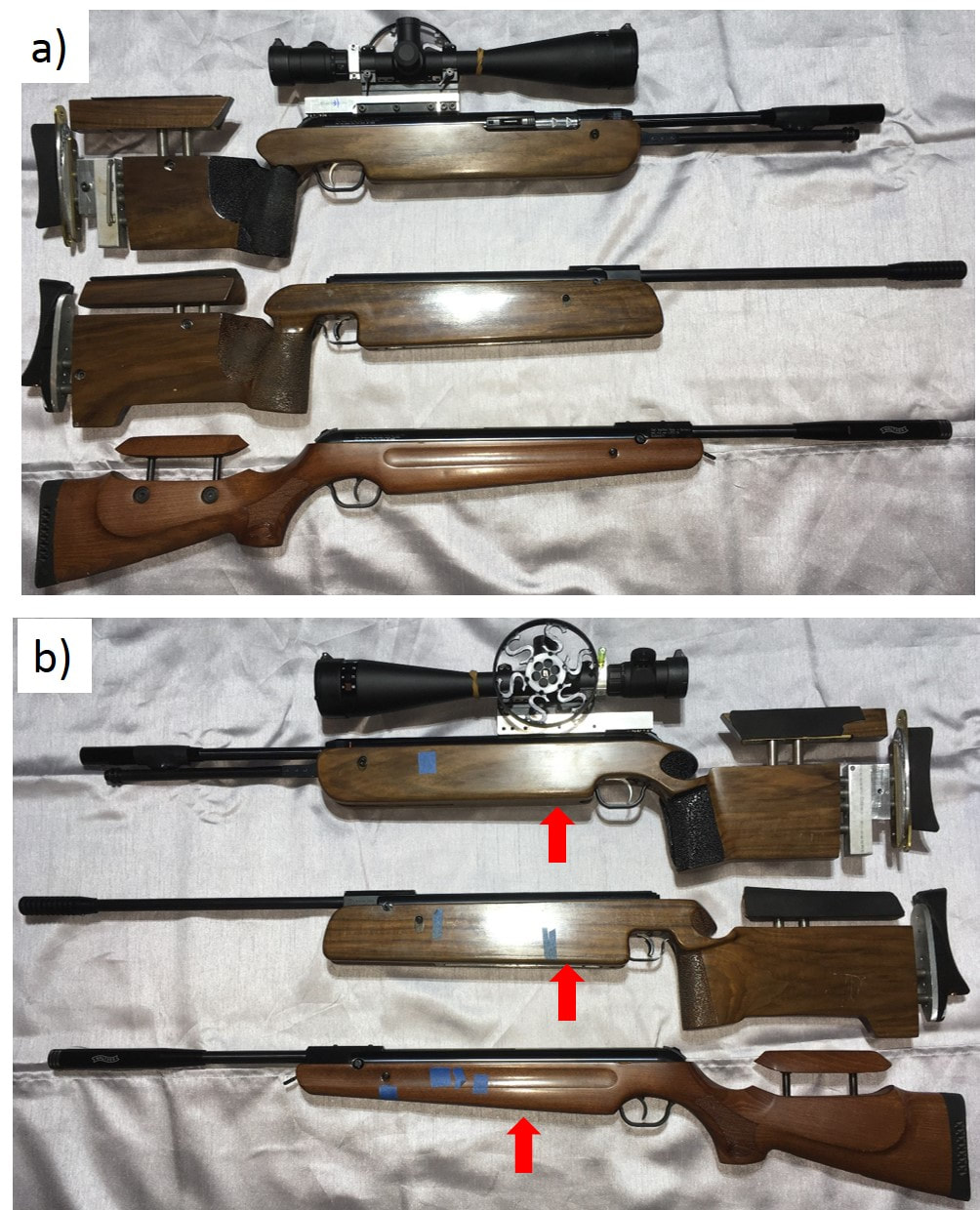

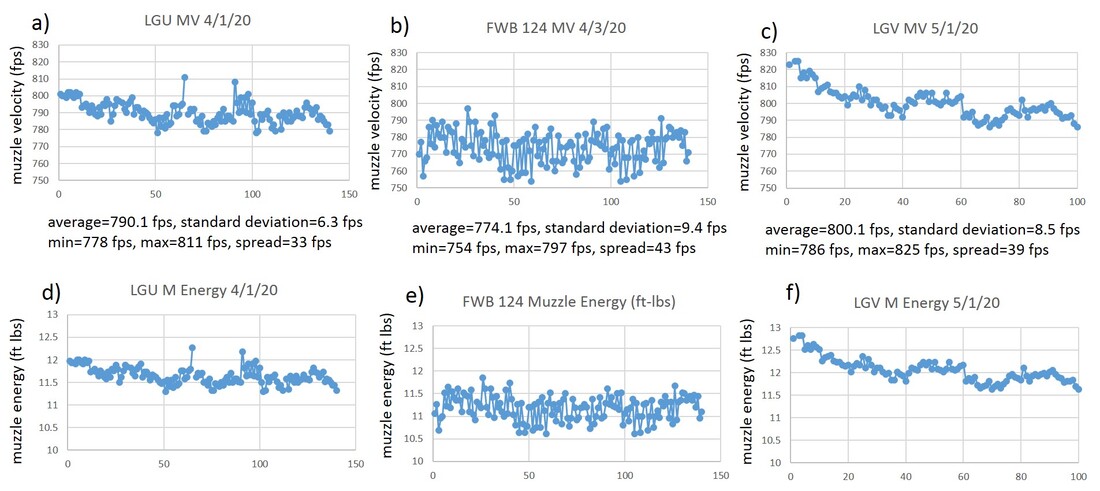

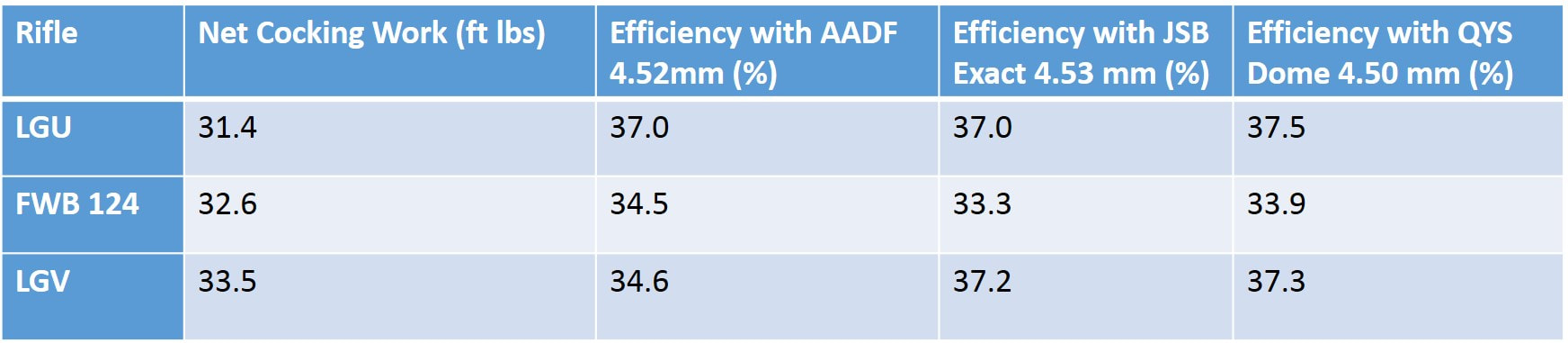

Being able to compare and contrast airguns allows us to see aspects that normally would be hidden or taken for granted. In this chapter we look at three German spring piston air rifles in 0.177 caliber with muzzle energies around 12 ft-lb Figure 2.1 shows the three air rifles. In all the tests, I mounted the same Sightron SIIISS1050X60FTIRMOA-H scope.

The Walther LGU

Walnut stock is homemade. The receiver is glass-bedded and all the stock screws are pillar-bedded with aluminum tubes. For more info on the stock, please see:

https://www.gatewaytoairguns.org/GTA/index.php?topic=164358.0

I also modified/changed some of the metal parts. The trigger is from Tony Leach:

https://www.airgunforum.co.uk/community/index.php?threads/tony-leach-lgu-trigger-blade.253470/

https://www.airgunnation.com/topic/walther-lgu-lgv-a-new-trigger-option/

I replaced the 15 ft-lb factory spring with a 12 ft-lb Walther LGU spring so that the rifle could be used in World Field Target competitions. I removed the muzzle cap and built a magnetic latch to hold the barrel in place. The original detent barrel latch was hard to use when wearing a shooting mitt and I was concerned that it may have been stressing the barrel. The weight of this rifle with the Sightron scope is 16.3 lbs. The scope with base and rings weighs about 3.4 lbs. For more details on these modifications, please see:

https://www.gatewaytoairguns.org/GTA/index.php?topic=168525.0

The FWB 124 was my first high quality air rifle that I bought in the early 1980’s. I installed the Maccari (Air Rifle Headquarters) Slightly Softer Mainspring kit. I made the stock out of the same walnut blank that was used for my LGU. The reason that there’s an aluminum block at the butt end of the LGU stock is that I didn’t have enough wood left for the LGU after making my FWB 124 stock! The trigger is a Maccari (Air Rifle Headquarters) stainless steel trigger. As with my LGU, the receiver is glass-bedded and all the stock screws are pillar-bedded with aluminum tubes. The weight of this rifle with the Sightron scope is 14.3 lbs. For more background on this rifle, please check out my post on the FWB 300S vs FWB 124 shootout:

https://www.tapatalk.com/groups/yellow/fwb-124-and-fwb-300s-shootout-t239102.html

The Walther LGV belongs to Hector. He custom-tuned it with an anti-bounce piston (ABP). The ABP has a cavity in an enlarged piston stem that holds a non-Newtonian fluid steel. The enlarged stem also functions as a spring guide, it just happens to be inside the piston, not at the rear, as usual. The fluid steel holds a shape (behaves like a solid) when accelerated or under pressure, but when acceleration becomes zero (as when the bounce cycle starts), then the steel becomes fluid again and tries to remain in position by its internal inertia. So the piston is stopped from bouncing and the piston, by holding the position in the compression chamber, maintains the pressure behind the pellet, so that with the same energy input, it can achieve almost 10% more muzzle energy. The weight of this rifle with the Sightron scope is 13.1 lbs.

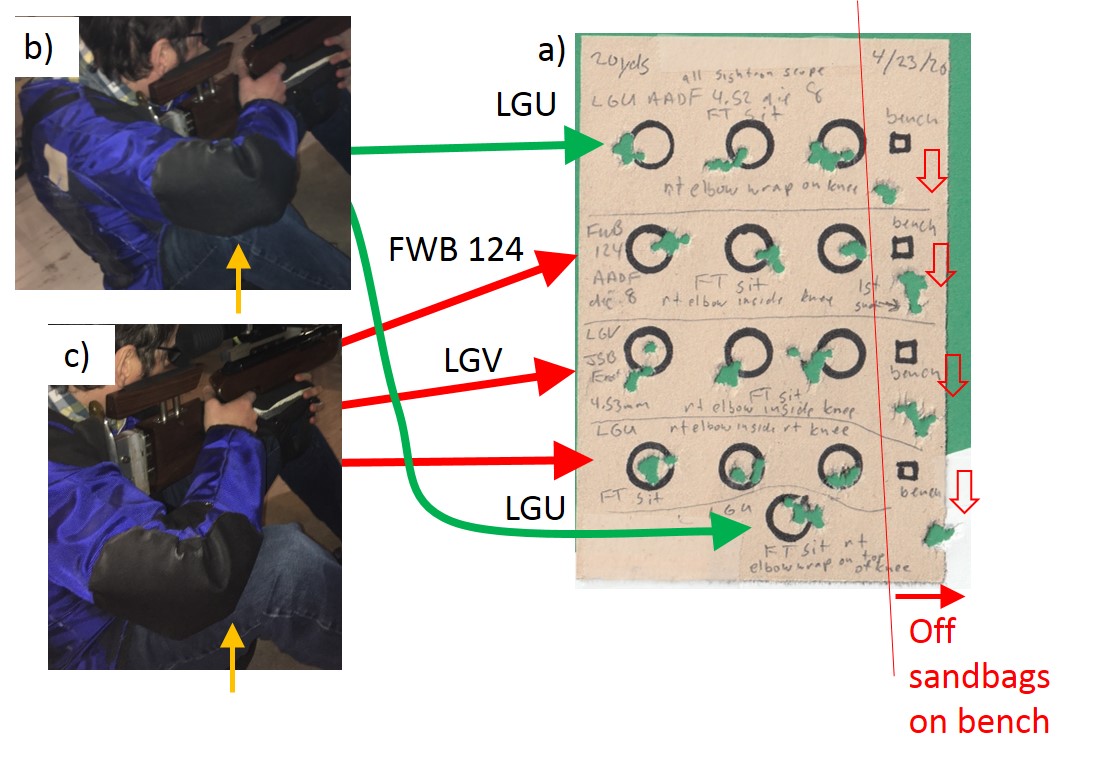

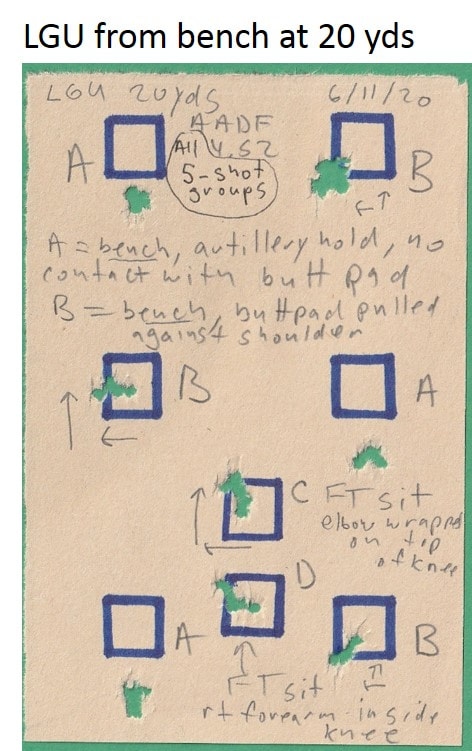

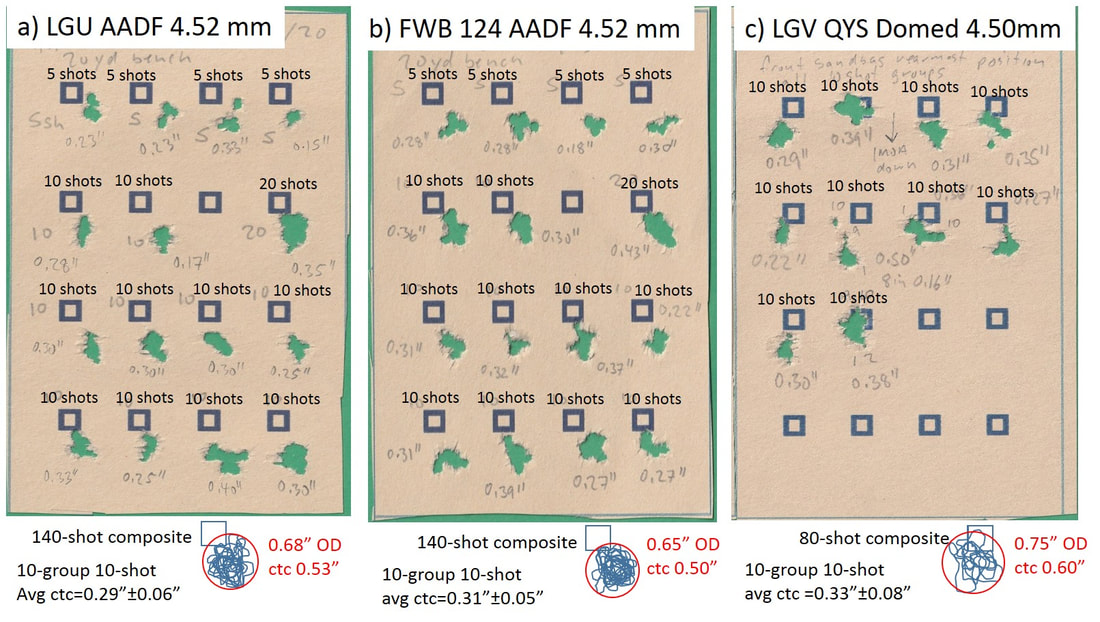

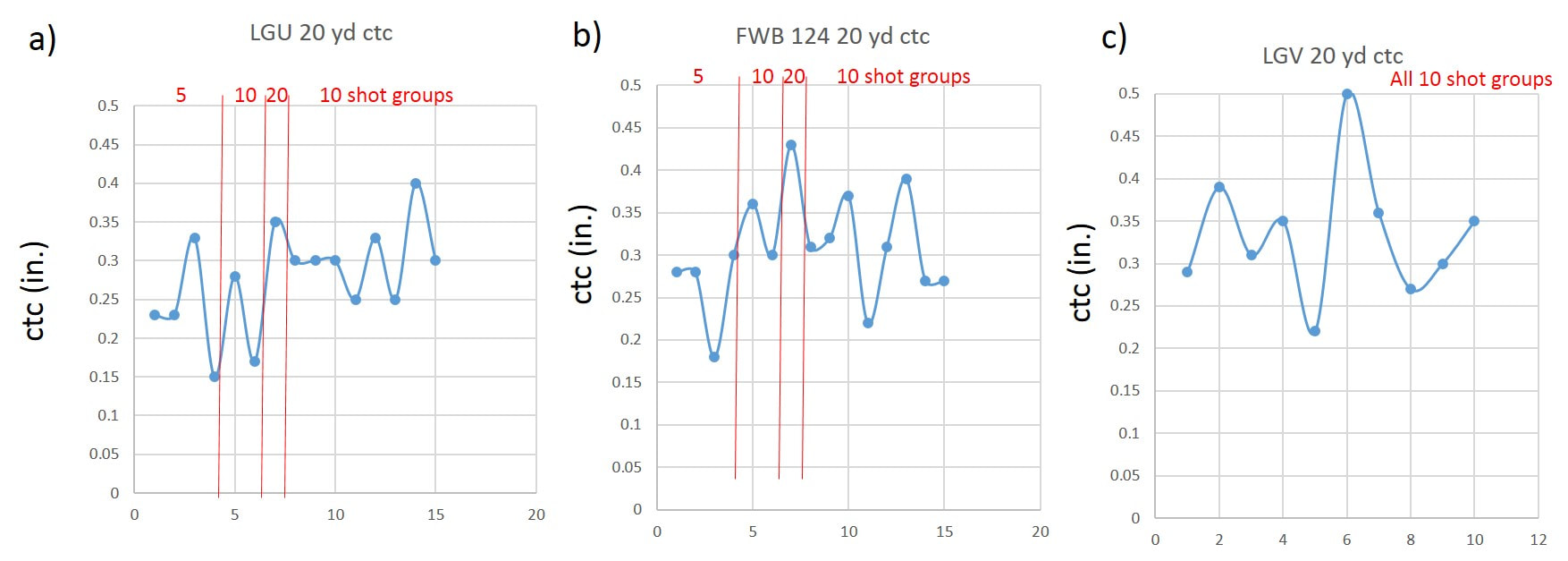

In Fig. 2.2 I test the accuracy of these rifles at 20 yards. All the shooting was done indoors with the rifles rested on sandbags. In Chapter 3 we will discuss the statistics of group sizes, but I think the key point is that one needs to shoot multiple groups. A single 5-shot, or even a single 10-shot group, doesn’t really say much about accuracy. Maybe it’s just my scientific skepticism, but if someone shows me an amazing 5-shot one-hole group, my first question would be what did the group right before or after that one-holer look like?! With a high quality 50x scope and a solid rest, operator error has been pretty much removed and the group sizes and positions are strictly due to the rifle.

I could have simply shown the best groups for these rifles, for example the 0.17” 10-shot group for the LGU, the 0.22” 10-shot group for the FWB 124, and the 0.22” 10-shot group for the LGV, but this would not be telling the whole story and could even be misleading. If the groups were shot outdoors and I had to contend with wind, then it would make more sense to discard bad groups due to wind and focus on the best groups where wind was less of an issue. However, with these tests indoors, there are no external factors except for the rifle itself to blame for larger groups. The best groups here are simply due to luck, where fluctuations in the rifle/pellet system happened to cancel each other out better for one particular string of shots! In most sports, it makes sense to talk about personal bests, so I think we tend to use the best group that a rifle makes to judge its accuracy. However, as we will see in Ch. 3, there is a lot of randomness involved in a single 5-shot or 10-shot group. There is a reasonably good chance (1 in 36) that one could roll the same number three times in a row with a six-sided die, but does that make that die special? Any other die would have the same probability of achieving that remarkable string of rolls!

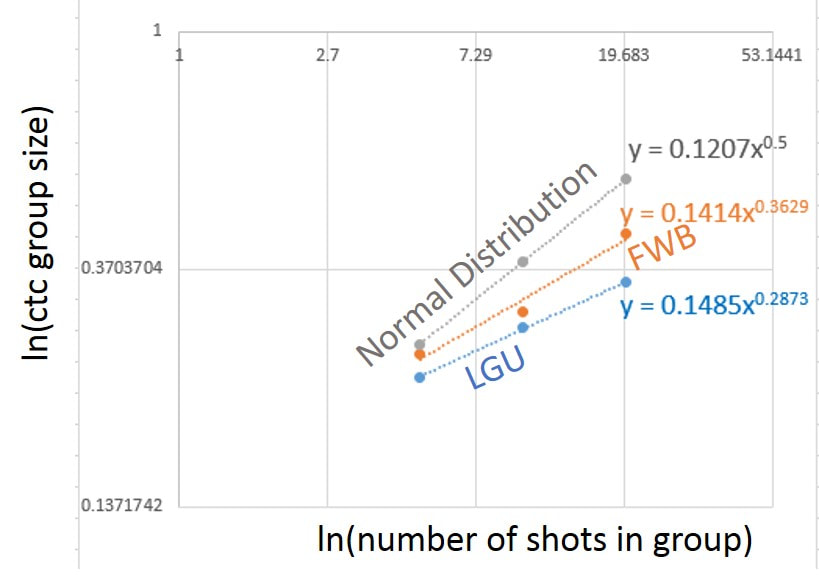

Figure 2.3 plots the ctc distance for each group. One can clearly see the fluctuations in ctc distances. In Figs. 2.3 a) and b) we can also see how the ctc distance varies with the number of shots in each group for the LGU and FWB 124, respectively. The 5-shot groups tend to be a bit smaller, but not by that much! In a purely random normal distribution (bell curve) one would expect the range of values to increase as one includes more samples. For example, if you measure the height of 20 students in a small classroom, the range of heights you get will be smaller than if you measure the height of 300 students in a large classroom (there’ll be a better chance that some really short and some really tall students can be found in the large classroom). For a normal distribution, this range of values should increase as the square root of the number of samples (in this case the number of student heights measured). Instead of looking at student height, here we are looking at where different shots land on the target. If we include more shots, there’s a better chance that one shot will land farther from the others. However, the group size (analogous to the range of heights in the student example), does not scale as the square root of the number of shots. If that were the case, the 10-shots groups should be 1.4 times bigger than the 5-shot groups (number of shots is twice as large, so we need to multiply the ctc distance by √ 2 = 1.4) and the 20-shot groups should be 1.4 times larger than the 10-shot groups and 2 times larger than the 5-shot groups. It would help if we had a few more 20-shot groups to get a better idea of the average 20-shot group size, but I think it’s clear that were not seeing bell curve scaling of the ctc distance with the number of shots in these groups.

https://www.gatewaytoairguns.org/GTA/index.php?topic=168525.0

This is a wonderful two stage trigger that comes pretty close to the light weight and crispness of the triggers on my Anschütz 2002CA and FWB 300S! This trigger changed the way I shoot at FT matches. I simply let the rifle sit where it wants and can pull the trigger without moving the rifle off target.

Hector modified his LGV trigger by adding longer adjustment set screws. The trigger pull is a bit heavier than the Leach trigger, but it is more than light and crisp enough for a clean trigger pull that doesn’t disturb one’s aim. Photos and a more detailed description can be found at:

https://www.ctcustomairguns.com/hectors-airgun-blog/a-yankee-tune-for-the-walther-lgu

Unfortunately, the FWB 124 doesn’t have the multilever lever arrangement with adjustable engagement points like the LGV and LGU, which use the same trigger and are very similar in design to the Weihrauch Rekord and Air Arms TX 200 triggers. However, with careful honing of the engagement surfaces and adjusting the pull weight screw so that one just barely feels the second stage engage, one can get a pretty good trigger pull in the FWB 124. I had a hard time figuring out how the FWB 124 trigger works and found the article below to be very helpful:

https://forum.vintageairgunsgallery.com/feinwerkbau-rifles/feinwerkbau-modell-124/

In my FWB 124 I replaced the factory aluminum trigger blade with a solid stainless steel trigger blade from Jim Maccari at Air Rifle Headquarters. I could feel the original aluminum trigger flex as the shot was about to be released, but that’s not a problem with the beefy stainless steel trigger. One can lower the pull weight by backing the adjustment screw out to the point that one loses the second stage, but this results in a long (albeit fairly light) pull with no hint of when the rifle will fire. By screwing in the adjustment screw until one can just barely feel the second stage engage, one can get a very predictable two-stage pull. On my FWB 124, the trigger feels like it snaps into a position as the second stage engages, and then it takes only a bit more pressure to release the shot.

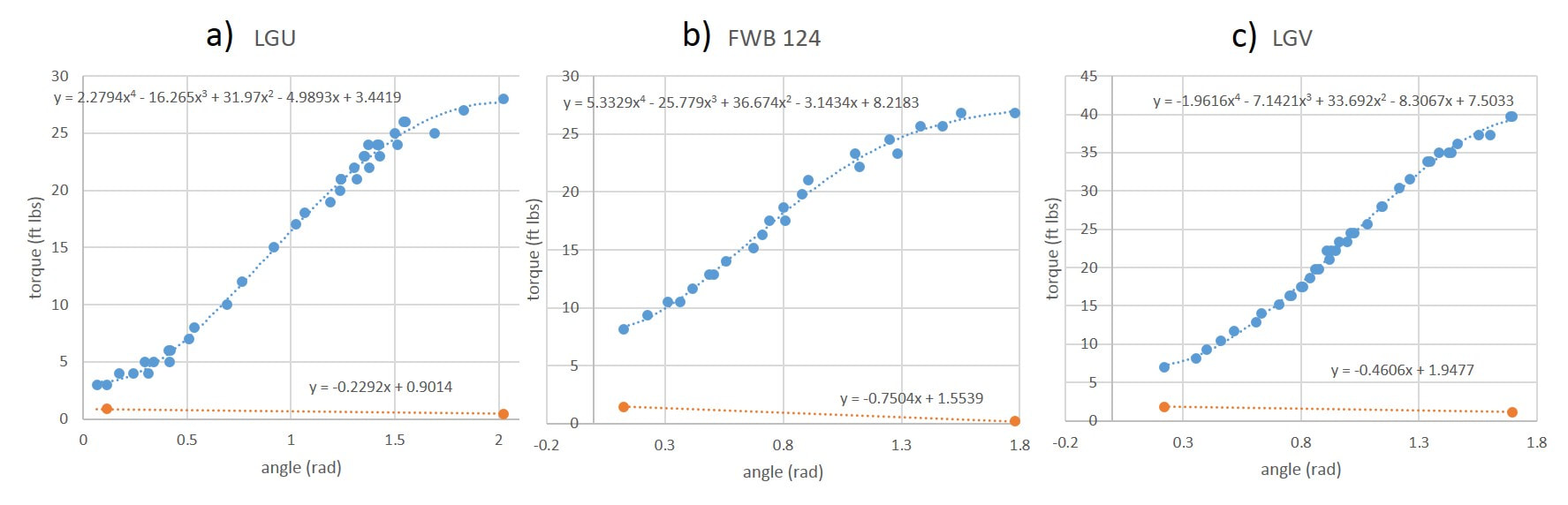

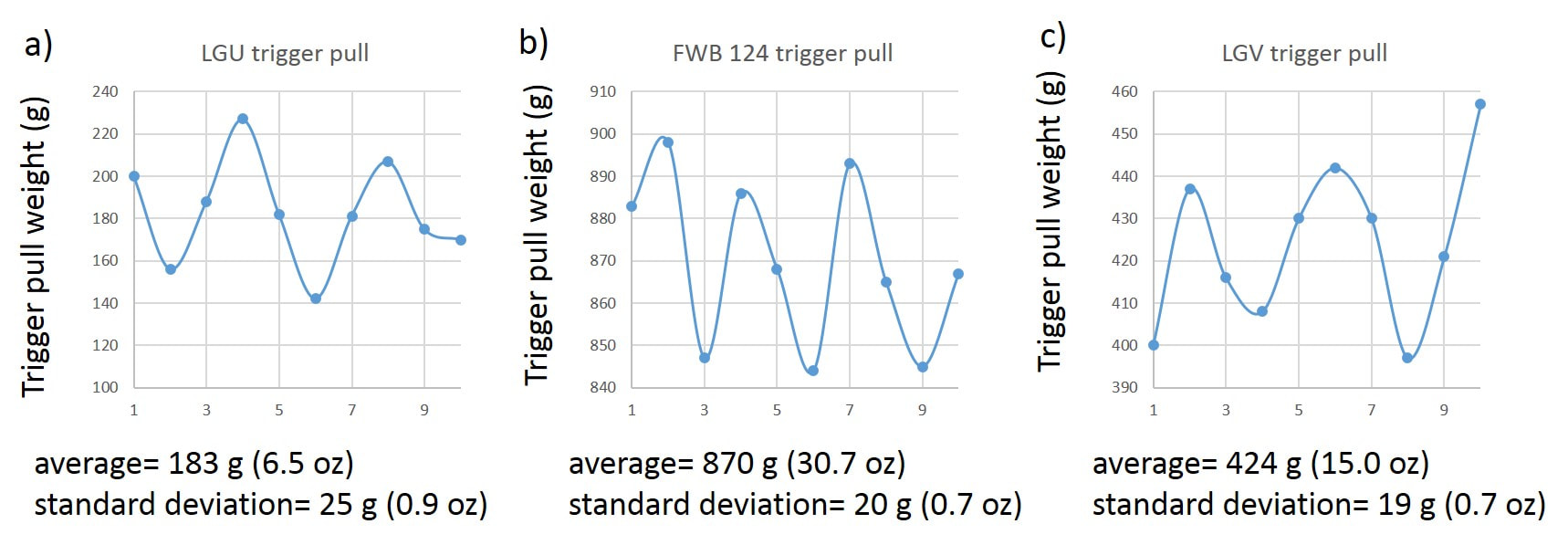

Figure 2.10 shows the trigger pull weight for 10 shots with the a) LGU, b) FWB 124, and c) LGV. The light pull weights on the LGV and LGU make them easier to shoot accurately, but the FWB 124 trigger also works great. The pull weights are also quite consistent.

I recently built a system to measure Pellet Dwell Time (time from trigger pull to pellet leaving the muzzle). I placed a contact microphone on the receiver tube near the trigger, which picks up the sound of the sear tripping. The signal from the microphone is sent to one of the channels on the oscilloscope, and the other channel records the light gate signal, allowing the time between sear release and pellet exit to be measured. This setup is too new to be included in this series, but I hope to post the results someday soon.

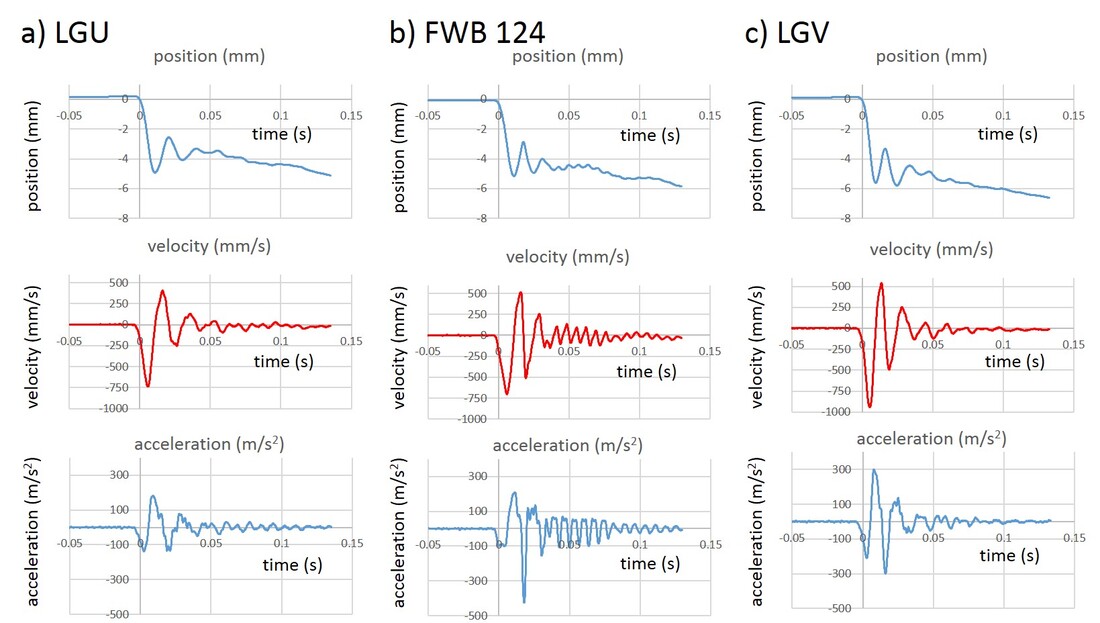

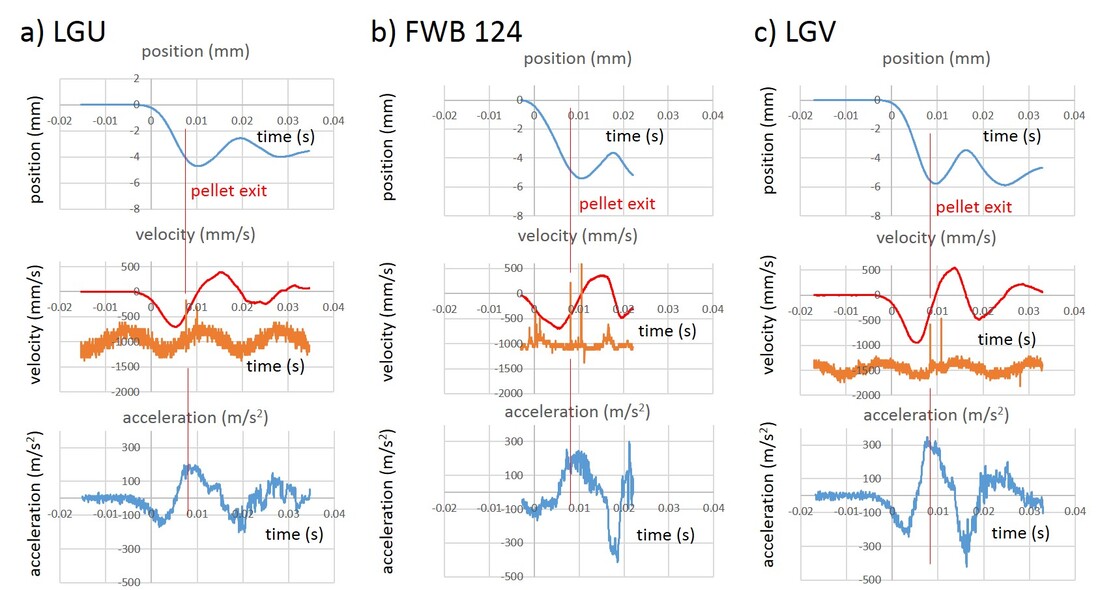

Now one can see more clearly that the initial backward acceleration of all three rifles is smaller than the forward acceleration when the piston bounces, which is consistent with the picture of the initial gradual push that the spring imparts on the piston and the more abrupt bounce of the piston backward when it reaches the front end of the compression chamber. One dramatic difference is that the first dip in the backward acceleration of the FWB 124 (-130 m/s²) is significantly smaller in magnitude compared to the dips in the backward accelerations of the LGU (-150 m/s²) and LGV (-244 m/s²). I think that this is due to the longer and softer spring in the FWB 124 compared to the shorter and stiffer springs in the LGV and LGU. The preload in the FWB 124 is around 1.5” while the LGU and LGV have only about 1” of preload. Since the LGV and LGU get more energy out of their springs with less preload than the FWB 124, they must have stiffer springs. It would be very interesting to see what longer and softer mainsprings in the LGU and LGV would do to their recoil cycles. I agree with Jim Tyler in his July 2018 Airgun World column, that softer springs with more preload can soften piston bounce and improve accuracy. Although the reduction in backward acceleration of the FWB 124 is consistent with a softer spring, it doesn’t look like the peak positive acceleration at the piston bounce is reduced that much compared to the LGU. To test this, we really should try different springs and preloads in the same rifle, rather than comparing different rifles with different preloads. When the piston bounces back, the rifle moves forward and one gets a peak in the rifle velocity in the red traces in Fig. 2.12. According to that peak, the anti-bounce piston mechanism does not appear to be significantly decreasing the piston bounce in the LGV compared to the LGU and FWB 124.

On the other hand, since the pellet has left the rifle before the rifle starts moving forward, maybe we shouldn’t be so concerned with piston bounce, at least as far as accuracy is concerned? Of course, it would be much better to try a regular piston in the same LGV rifle and compare it to the ABP results, rather than comparing with other rifles. We’ll take another look at this in Ch. 4. Now that we have the capability to record the recoil traces with sub-ms time resolution, we can see with great detail what tuning is doing to the recoil cycle!

RSS Feed

RSS Feed